Broken warp capture device of water jet loom

A water-jet loom and capture device technology, applied to looms, auxiliary weaving equipment, textiles, etc., can solve the problems of excessively long warp yarn breakage, reduce work efficiency, increase yarn cost, etc., and achieve large working area, Prevent interlacing and improve the effect of capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

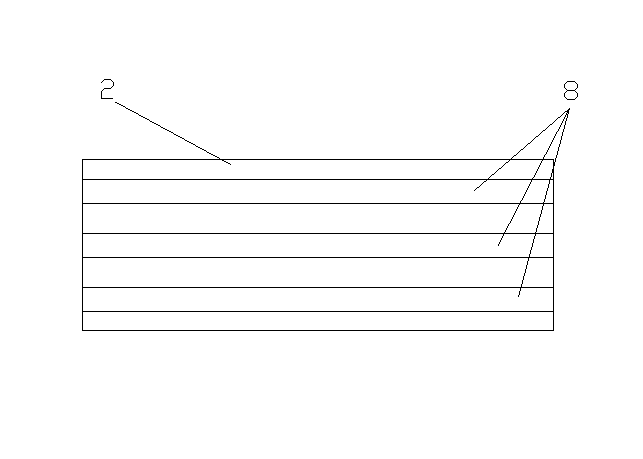

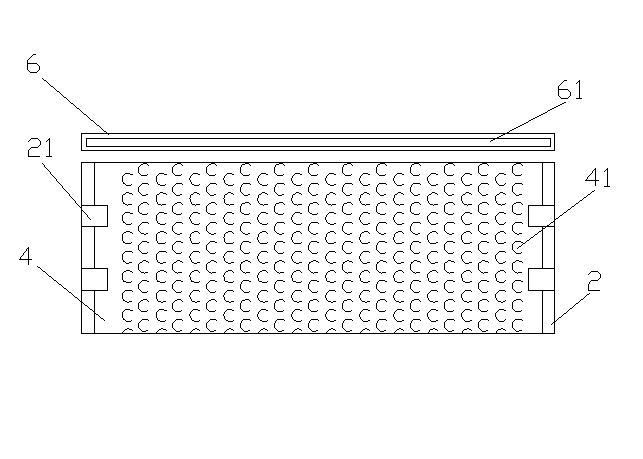

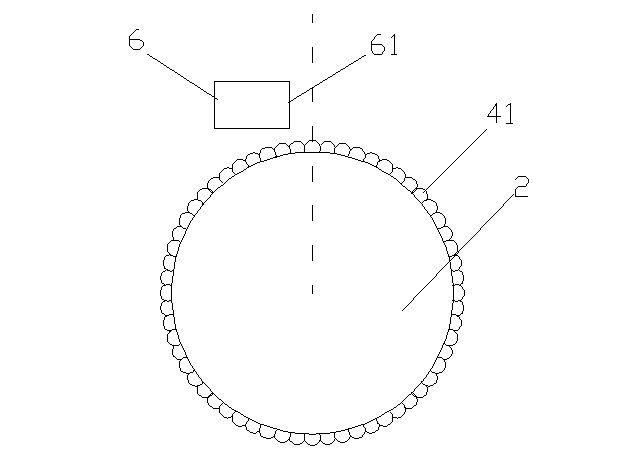

[0018] Such as Figure 1-3 As shown, a broken thread catching device of a water jet loom according to the present invention comprises a thread catching roller 2 extending laterally with a rotating shaft, a hook and loop fastener 4 with loop-like protrusions 41 arranged on the outer peripheral side of the thread catching roller 2, and the menopause Mechanism and the suction blower 6 that is located at the wire catch roller 2 tops. The side of the thread catching roller 2 is provided with 4-12 strip grooves (not shown) evenly distributed in the circumferential direction, each strip groove extends along the axial direction of the thread catching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com