Concrete block for road construction and construction method

A concrete block and road construction technology, applied in the direction of roads, roads, pavements paved with prefabricated blocks, etc., can solve the problems of dilapidated roads and incompetent roads, and achieve simple construction, rapid speed, and convenient road repair and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

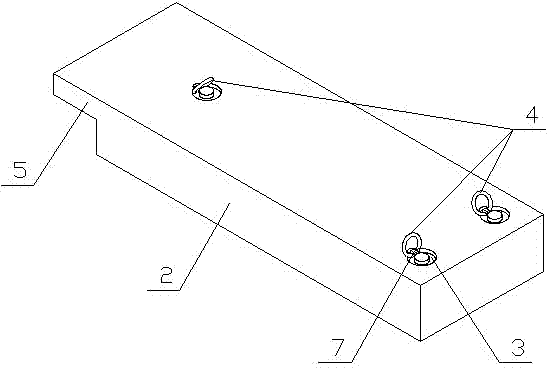

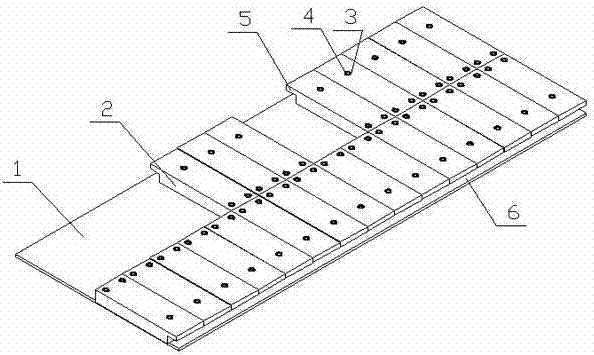

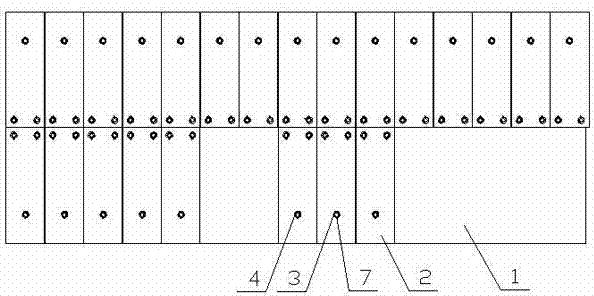

[0020] A concrete block used in road construction such as Figure 1 to Figure 3 As shown, the concrete block is laid on the roadbed 1. The concrete block includes a soil block body 2, at least three annular grooves 3 arranged on the soil block body 2, and a suspension ring 4 arranged in the annular groove 3. The annular The groove 3 matches the size and shape of the suspension ring 4, and one end of the soil block body 2 is provided with a convex strip 5, and the soil block body 2 is connected with the convex strip 5, and the soil block body 2 is connected to the roadbed through the convex strip 5. 1 to form a groove 6. A collar 7 is arranged in the annular groove 3 , and the suspension ring 4 is nested in the collar 7 .

Embodiment 2

[0022] The method of construction of concrete blocks for road construction is as follows:

[0023] The road subgrade 1 is divided into several road surface unit blocks, the shape of the soil block body 2 is long, and the length of the soil block body 2 is 1 / 2 of the width of the subgrade 1 .

[0024] It is set that one end of the soil block body 2 with the convex strip 5 is the front, and the other end is the reverse side, and the reverse sides of the adjacent two soil block bodies 2 are connected in pairs to form an integral unit soil block, and the fronts of the above two soil block bodies 2 Facing both sides of the subgrade 1 respectively; filling the above-mentioned integral unit soil blocks into the divided pavement unit blocks;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com