Pre-tensioned pre-stressing fender post

A technology of retaining piles and pretensioning, which is applied to sheet pile walls, excavation, construction, etc., can solve the problems of difficult control of pile body quality and steel welding quality, difficulty in mud treatment, pollution of the environment, troublesome construction of pile joints and high costs , to achieve the effect of improving the shear connection performance, convenient pile connection, and low joint cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

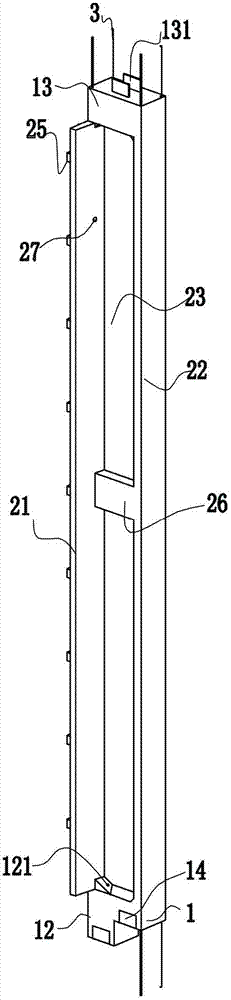

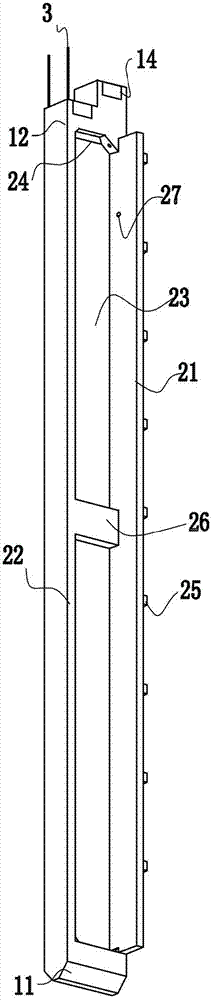

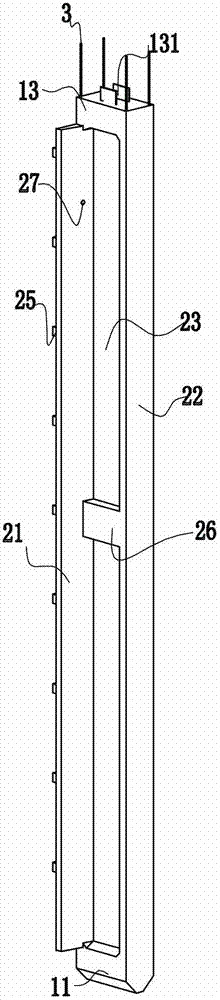

[0027] see figure 1 , Figure 4 with Figure 5 , the embodiment of a kind of pre-tensioned prestressed enclosure pile provided in the present invention, comprises pile head 1 and pile body 2, and pile body 2 is the I-shaped cross-section that upper flange 21 width is greater than lower flange 22, Pretensioned prestressed steel strands or steel wires 3 are embedded in the upper flange 21 and the lower flange 22 . The protective pile of the invention adopts an I-shaped section, has good bending resistance, can not only meet the strength requirement, but also can save materials and reduce costs. The use of prestressed steel strands or steel wires as the main reinforcement of the enclosure pile can greatly reduce the amount of steel used for the main reinforcement and reduce the bending deformation of the pile.

[0028] see figure 1 , figure 2 with image 3 , in the above-mentioned embodiment given by the present invention, the pile head 1 is composed of two kinds of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com