Magnetic eddy-current type kinetic energy-to-heat energy heat storing device

A heat storage device, magnetic eddy current technology, applied in the direction of engine, wind power generation, wind turbine, etc., can solve the problems of wind energy waste, wind speed lag, impact and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

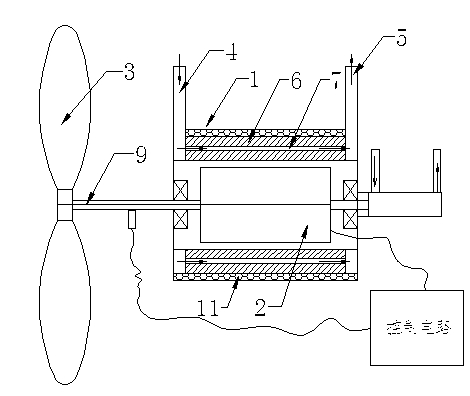

Embodiment 1

[0021] Such as figure 1 As shown, the magnetic eddy current type kinetic energy-to-heat heat storage device of the present invention includes a rotor 2 connected to the wind-driven blade shaft 9 and a stator 1 sleeved outside the rotor. The blades 3 are installed on the blade shaft 9 and can be placed outside Under the action of the driving force, the rotor 2 is driven to rotate. One end of the blade shaft 9 is equipped with a cooling device 10 for cooling the rotor 2; the stator 1 is covered with a layer of thermal insulation material 11; the rotor 2 is provided with an excitation coil, and there is a control The device 12 can control the magnetic field that the rotor acts on the stator; the stator 1 is provided with a heating element made of a ferromagnetic material that can induce changes in the magnetic field and generate eddy currents, and a heat storage space that can be filled with a heat exchange medium is provided in the stator 1, The heat storage space is connected t...

Embodiment 2

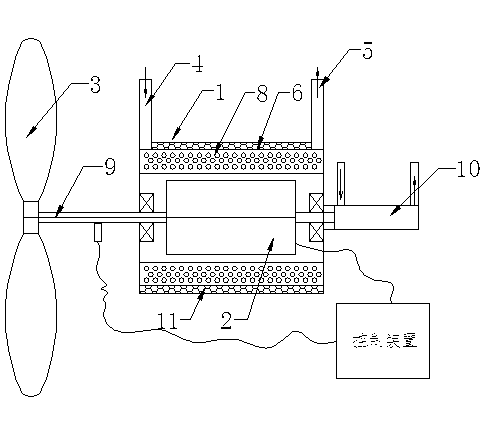

[0023] Such as figure 2 As shown, in this embodiment, the magnetic eddy current type kinetic energy-to-heat heat storage device of the present invention includes a rotor 2 connected to the wind-driven blade shaft 9 and a stator 1 sleeved outside the rotor, and the blades 3 are installed on the blade shaft. 9 and can drive the rotor 2 to rotate under the action of an external driving force. A cooling device 10 for cooling the rotor 2 is installed at one end of the blade shaft 9; the stator 1 is coated with an insulating material layer 11 on the periphery; The coil has a control device 12 that can control the magnetic field that the rotor acts on the stator; the stator 1 is provided with a heating element made of a ferromagnetic material that can induce changes in the magnetic field and generate eddy currents, and at the same time, a heat exchange medium can be filled in the stator 1 The heat storage space is connected to the external circulation heat exchange system through th...

Embodiment 3

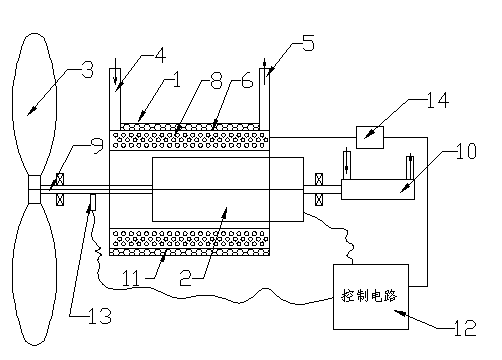

[0025] Such as image 3 As shown, in this embodiment, the magnetic eddy current type kinetic energy-to-heat heat storage device of the present invention includes a rotor 2 connected to the wind-driven blade shaft 9 and a stator 1 sleeved outside the rotor, and the blades 3 are installed on the blade shaft. 9 and can drive the rotor 2 to rotate under the action of an external driving force. A cooling device 10 for cooling the rotor 2 is installed at one end of the blade shaft 9; the stator 1 is coated with an insulating material layer 11 on the periphery; The coil has a control device 12 that can control the magnetic field that the rotor acts on the stator; the stator 1 is provided with a heating element made of a ferromagnetic material that can induce changes in the magnetic field and generate eddy currents, and at the same time, a heat exchange medium can be filled in the stator 1 The heat storage space is connected to the external circulation heat exchange system through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com