Hard alloy amphibious sand pump capable of being idled and connected in series

A cemented carbide, amphibious technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

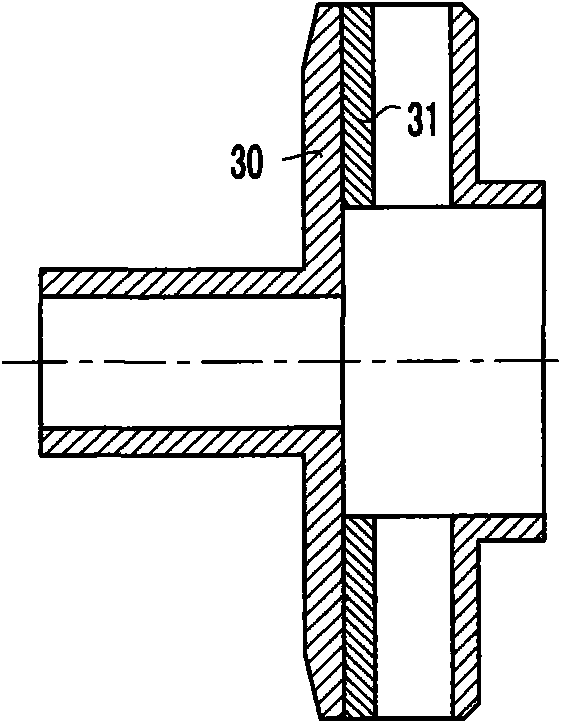

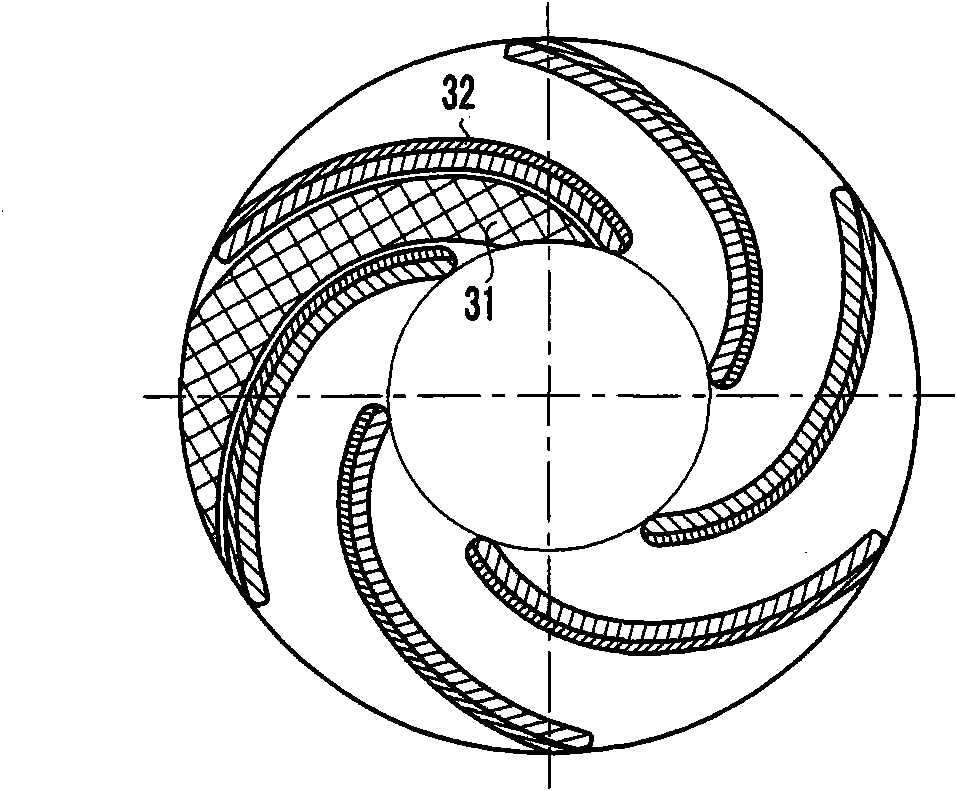

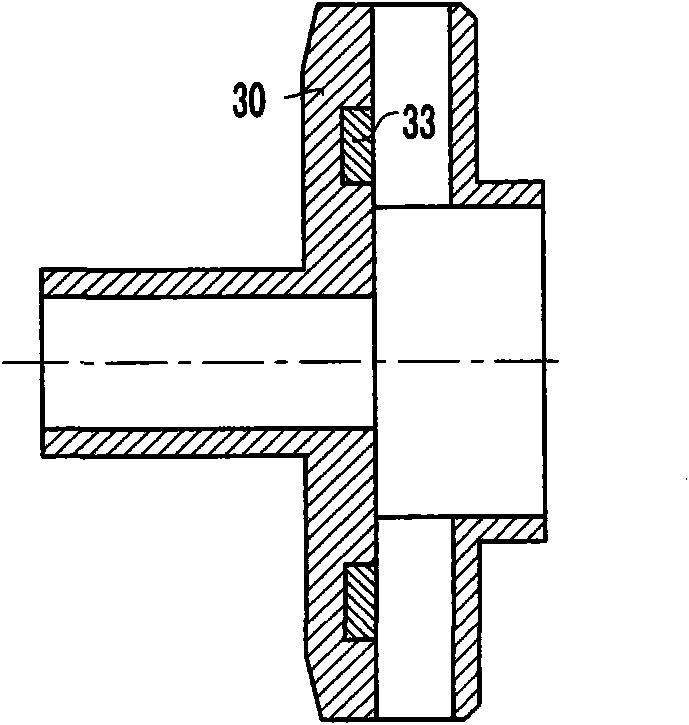

[0012] The following is a further description of the cemented carbide idling and series-connected amphibious sand pump of the present invention in conjunction with the accompanying drawings.

[0013] figure 1 The figure is the first embodiment of the cemented carbide sand pump that can be idling and can be connected in series for amphibious purposes. Figure 1 to Figure 5 , is a schematic diagram of a cover plate made of wear-resistant alloy metal material and original metal material welded to the parts of the pump body and impeller where pits appear due to the high-speed impact of sand particles. This overlay can be Figure 5 The surface of the deflector in the body of the pump body 37 that is impacted by the water outlet of the impeller 38 at a high speed is welded with a wear-resistant alloy material to cover the cover plate 36 in the pump body, and its periphery is welded with the deflector on the surface of the original pump body .

[0014] Overlay panels can be figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com