Adjustable guide/stationary blade control device and method for axial flow compression system under variable working condition

A technology of compression system and control method, applied in pump control, non-variable-capacity pump, machine/engine, etc., can solve the problems affecting the efficient operation of the compression system, complex action mechanism, complex measurement signal, etc., to achieve control capability and processing Increased speed, intuitive measurement control, and easy handling of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

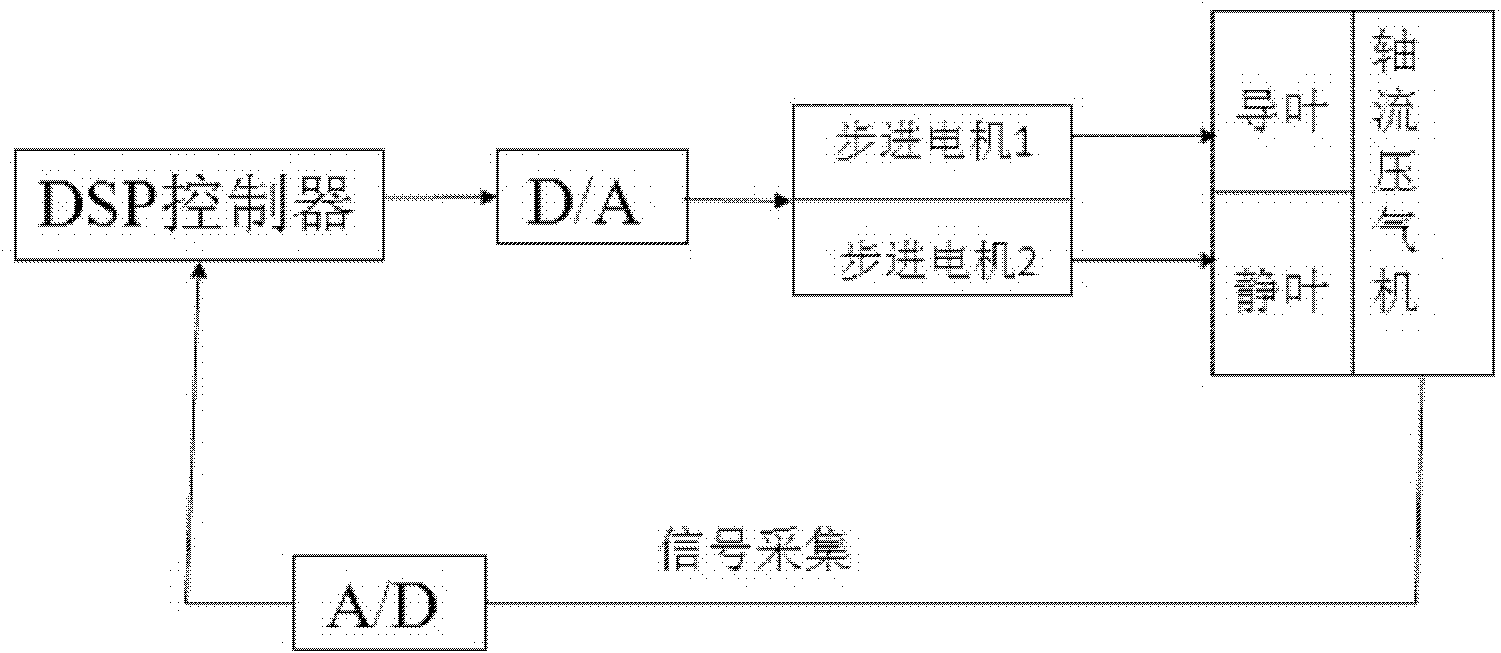

[0036] The adjustable guide / stator vane controller used for variable operating conditions of the axial flow compression system of the present invention has been tested on a three-stage axial flow compressor test bench, and its flow block diagram is as follows figure 1 shown.

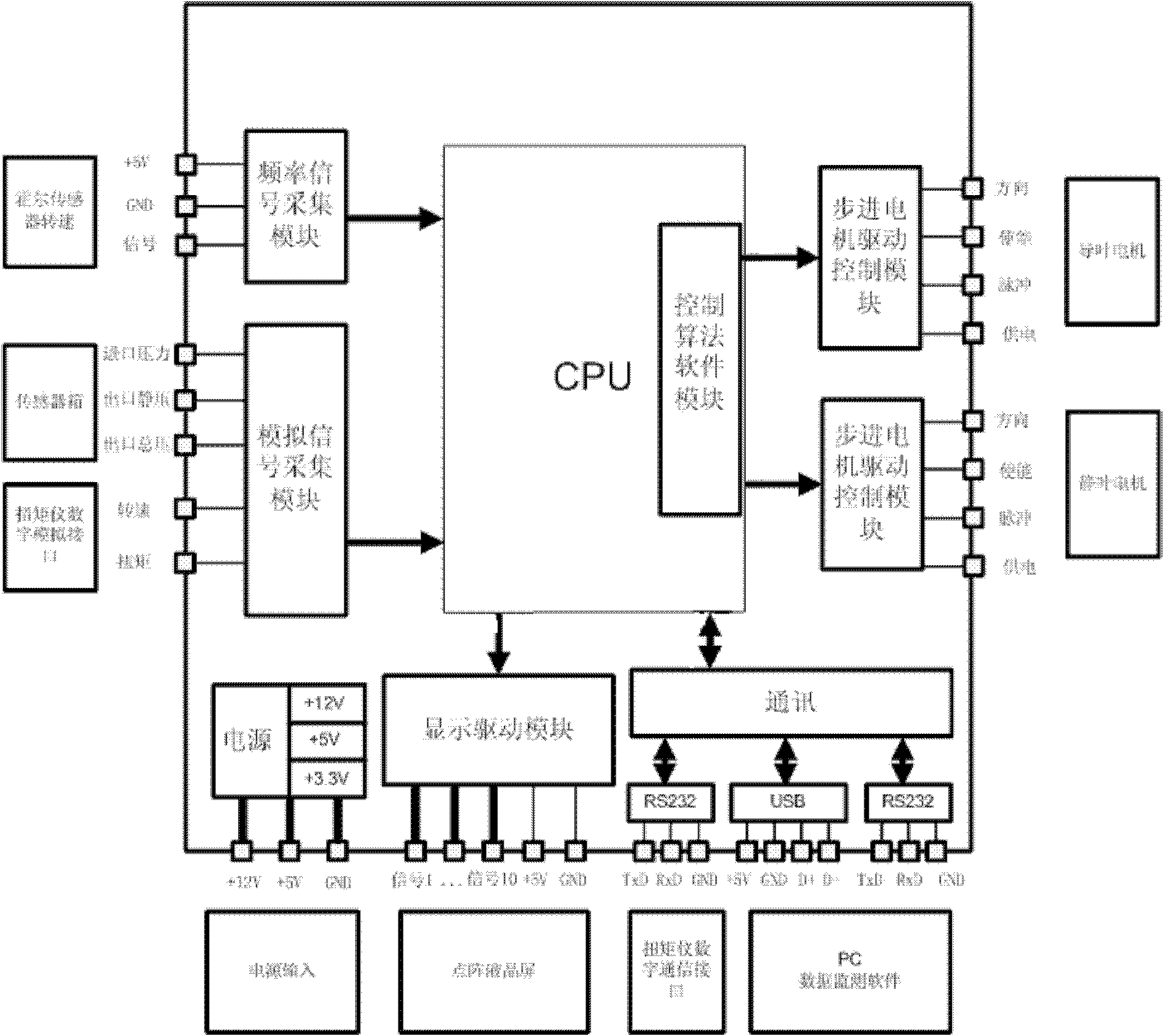

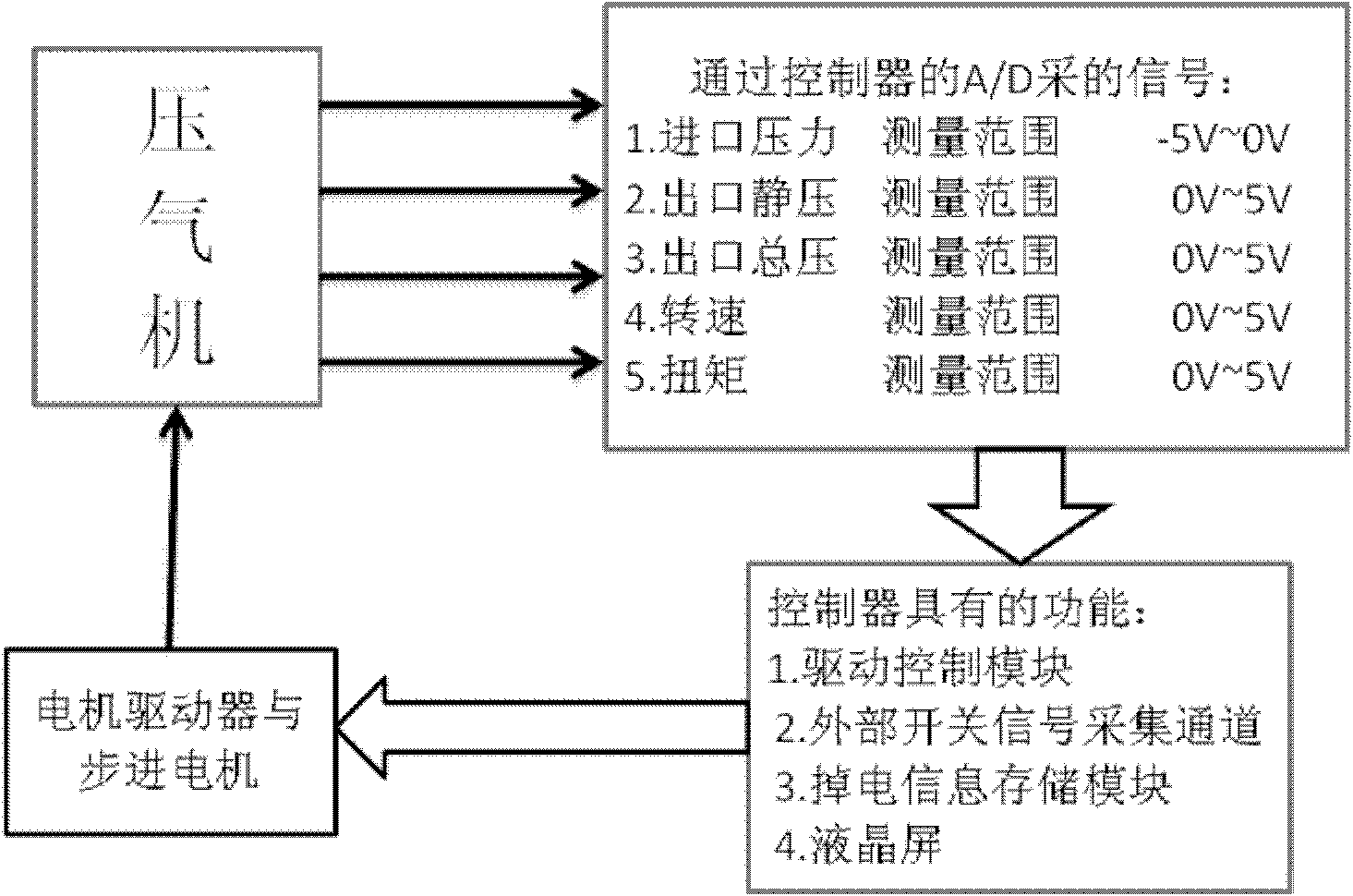

[0037] The structure of the controller is as figure 2 As shown, in the experiment, the static pressure at the inlet and outlet of the axial flow compressor, the total outlet pressure, and the speed and torque are collected, and input through the A / D port of the controller. The controller uses an embedded operating system and a 32-bit signal processor , the controller has real-time processing capability, small size, high calculation accuracy, and can replace the role of the computer in the actual complex operating environment. After calculating the efficiency value of the current angle online in real time, the guide vane and The direction of the vane angle change, the angle signal is output from the D / A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com