Duplex constant-speed driving shaft

A constant-velocity drive shaft and intermediate shaft technology, used in couplings, elastic couplings, engine components, etc., can solve the problems affecting the performance output and safety of the vehicle, insufficient torque output, and insufficient strength. Improve the maximum bearable torque output, high torsional strength and good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

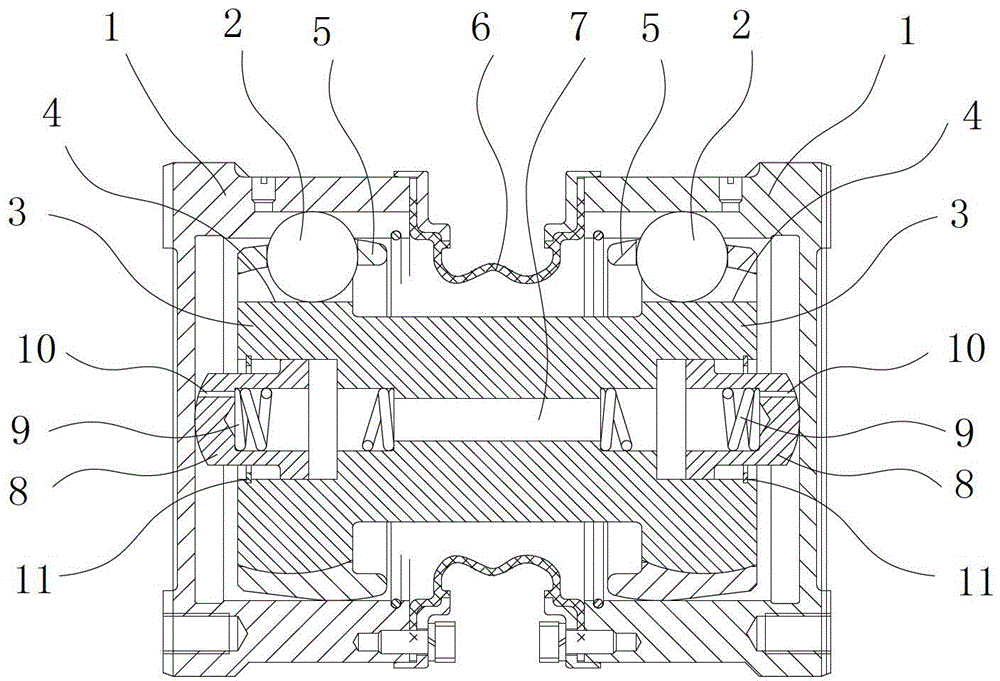

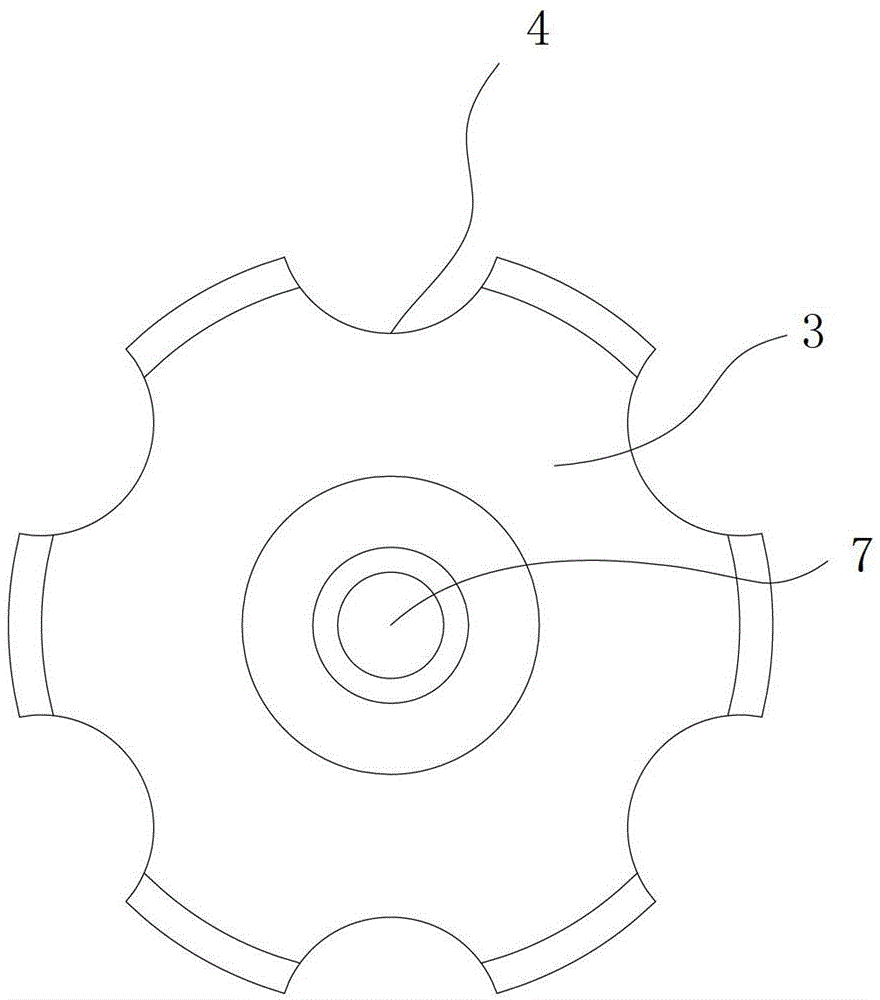

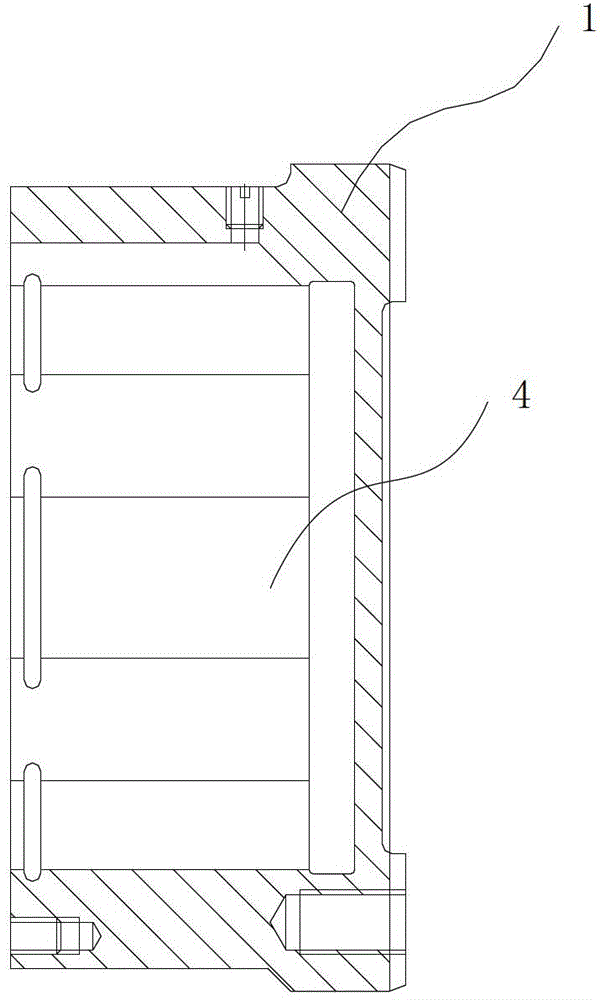

[0021] Such as Figure 1 to 5 As shown, a double-linked constant velocity drive shaft includes an intermediate shaft 3, both ends of the intermediate shaft 3 are respectively sleeved with a universal joint casing 1, and the side wall of the intermediate shaft 3 is sleeved on it Steel balls 2 are provided between the inner walls of the two universal joint casings 1 on the upper side, and steel balls 2 are provided on both side walls of the intermediate shaft 3 and the inner walls of the two universal joint casings 1. Fairway 4. A limit block 8 is provided between the end of the intermediate shaft 3 and the bottom wall of the universal joint casing 1 provided at the end, and the end of the intermediate shaft 3 is provided with a groove for accommodating the limit block 8. The groove is provided with a spring 9 which presses the limit block 8 to make the limit block 8 abut on the bottom wall of the universal joint casing 1 at the end. The inner wall of the groove is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com