A method for on-line detection of wear amount of slewing bearing and automatic filling of lubricating grease

A technology of slewing bearing and automatic filling, which is used in lubricating parts, engine lubrication, engine components, etc. It can solve the problems of changing and complex working conditions of slewing bearings, affecting the lubrication effect, and insufficient grease injection, and achieving real-time optimization of lubrication. conditions, good promotion and application value, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

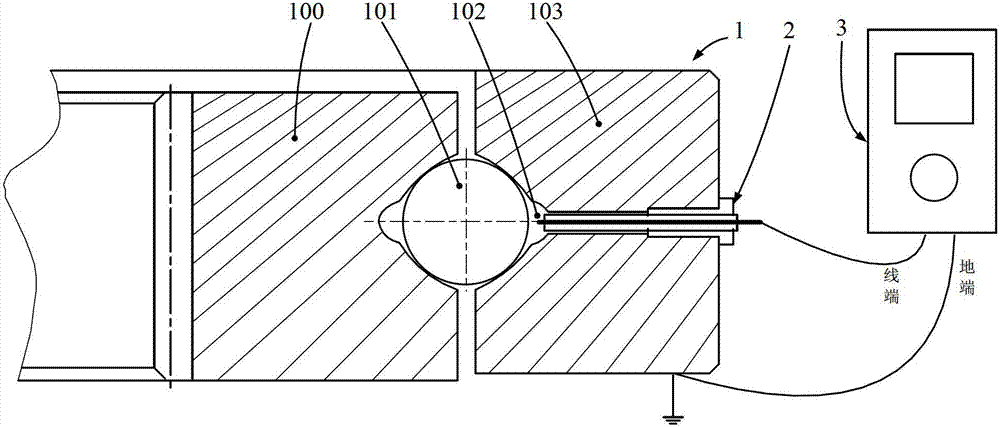

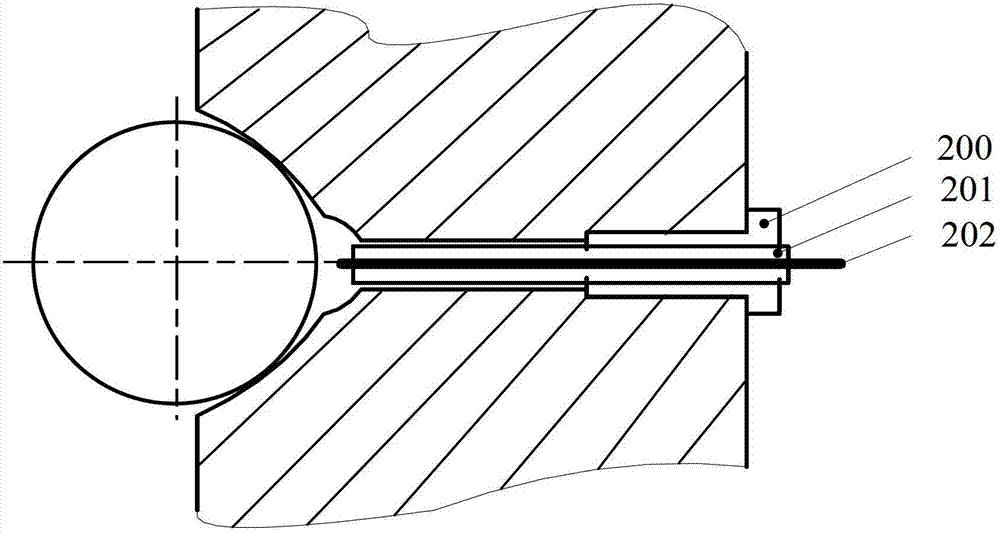

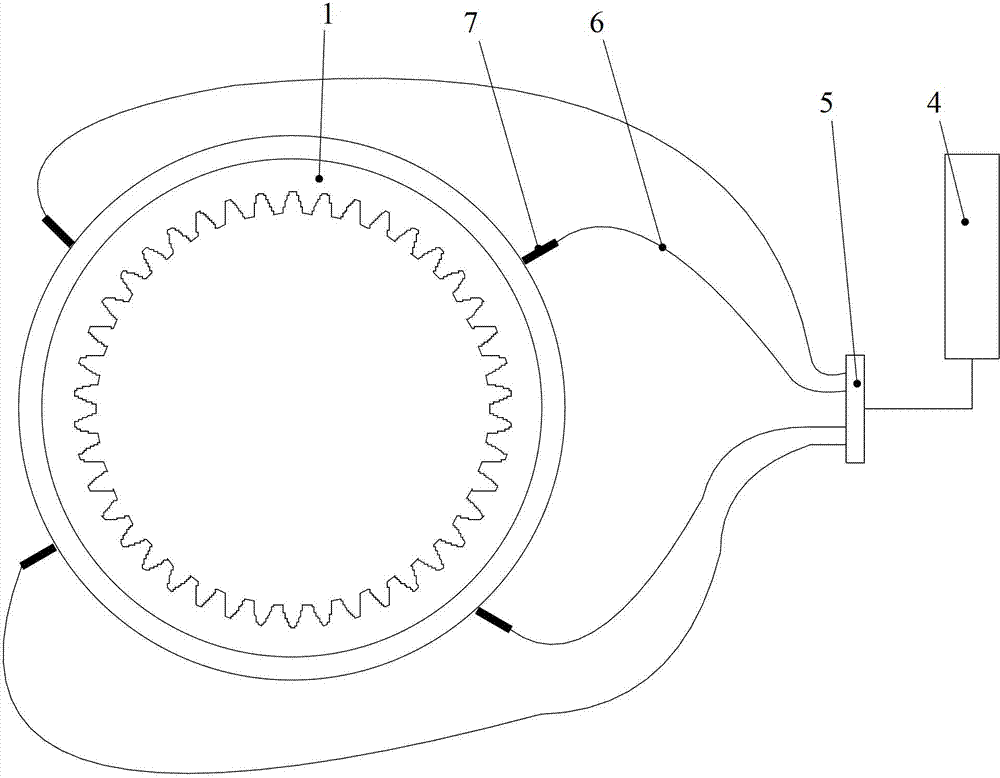

[0020] A method for on-line detection of wear amount of a slewing bearing and automatic filling of lubricating grease, including the step of judging the change of the content of metal particles in the lubricating grease by using the change of the insulating performance of the lubricating grease, that is, using the on-line wear amount detection system to measure the distance between the lubricating grease and the slewing bearing Insulation resistance value, the smaller the insulation resistance value, the more metal particles in the grease, so as to judge the wear condition of the slewing bearing raceway and judge whether to start the automatic grease filling system.

[0021] It also includes the step of determining the amount of grease injection and the interval between grease injection according to the insulation resistance value between the grease and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com