Method for scanning ultrasonic microscope and measuring thickness, sound velocity, density and attenuation of thin material simultaneously

A thin-layer material, ultrasonic technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, using ultrasonic/sonic/infrasonic waves, using sonic/ultrasonic/infrasonic waves to analyze solids, etc. The value selection is not good and other problems to achieve the effect of avoiding the convergence problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

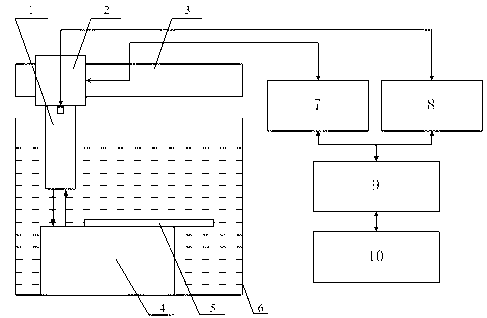

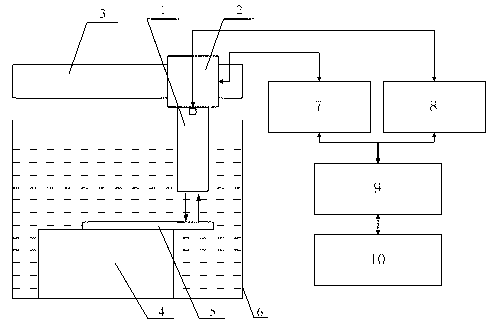

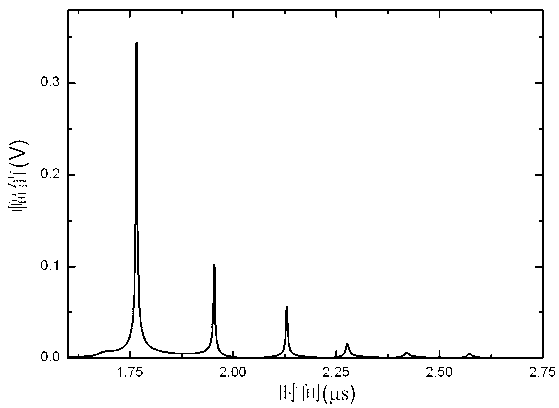

[0041] The scanning ultrasonic microscope is a method for simultaneously measuring the thickness, sound velocity, density and attenuation of a thin-layer material. A scanning ultrasonic microscope is used. The scanning ultrasonic microscope includes an ultrasonic probe 1, a three-dimensional linear motor 2, a guide rail 3, a base material 4, a thin-layer material 5, and a water tank 6 , motor controller 7, ultrasonic transmitter receiver 8, computer 9, display 10, base material 4 is placed on the bottom of the tank 6, thin layer material 5 is provided on the base material 4, ultrasonic probe 1 is arranged on the top of the base material 4, ultrasonic probe The upper end of 1 is connected with the three-dimensional linear motor 2, the guide rail 3 is provided with the three-dimensional linear motor 2, the ultrasonic probe 1 is connected with the ultrasonic transmitting receiver 8, the three-dimensional linear motor 2 is connected with the motor controller 7, and the computer 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com