Method for testing jitter and slippage of belt of engine gear train and swinging angle of tension roller

A test method and engine technology, applied in the field of slippage and tensioner swing angle, and testing the vibration of engine gear belts, can solve problems such as lack of performance, achieve the effect of preventing abnormal noise and failure, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

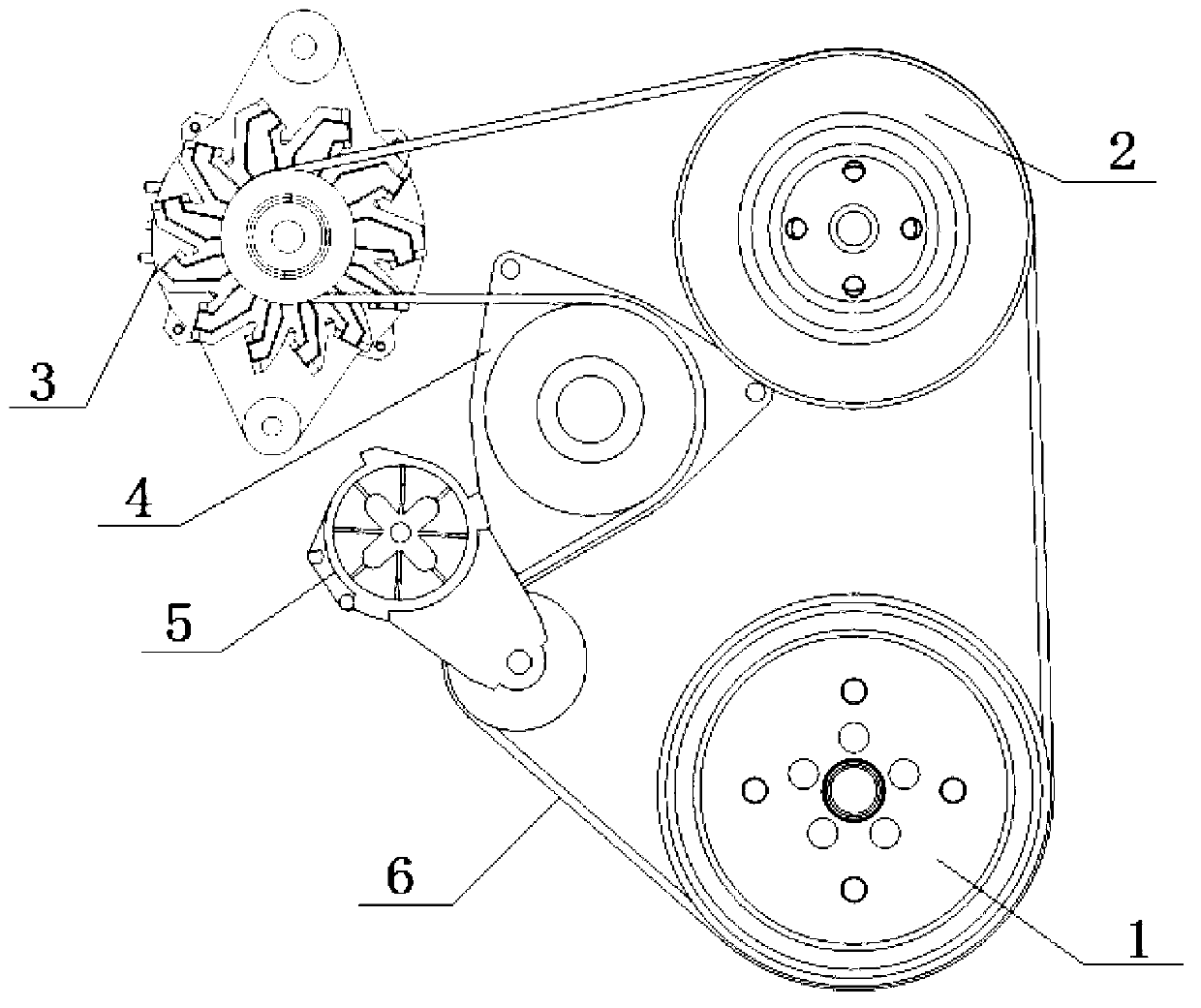

[0020] figure 1 It is a schematic diagram of the test gear train of the present invention: 1-crankshaft pulley 2-fan pulley 3-generator 4-water pump 5-automatic tensioner 6-belt, the embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

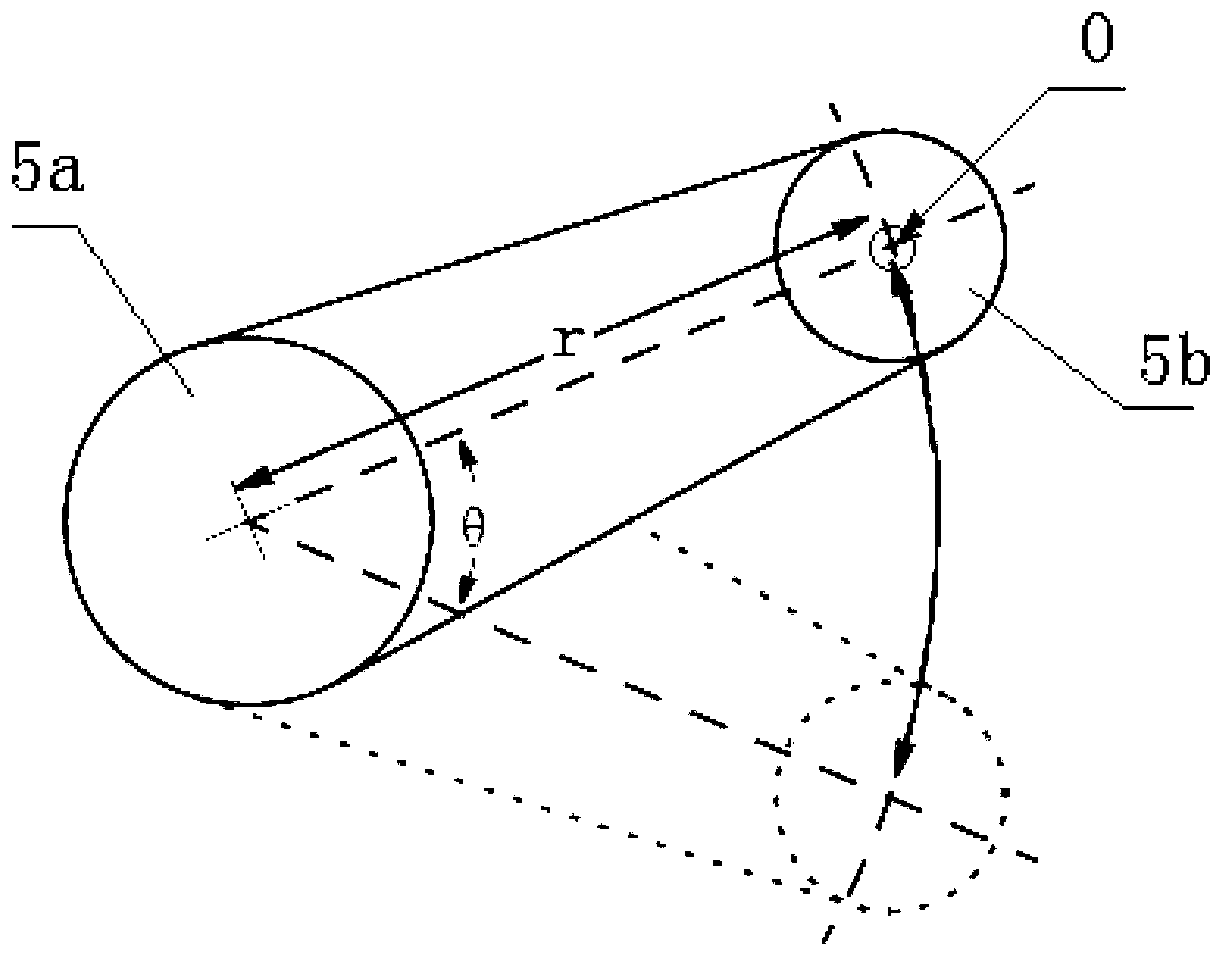

[0021] figure 2 It is a schematic diagram of the swing angle of the tensioner wheel movement of the present invention: 5a is the tensioner wheel mounting seat, 5b is the tensioner wheel, θ is the swing angle of the tensioner wheel, and r is the swing radius of the tensioner wheel.

[0022] 1: Test method for the jitter of the front wheel train belt of the engine:

[0023] see figure 1 , Test the amount of belt vibration D between the crankshaft pulley 1 and the fan pulley 2.

[0024] When the engine is stopped, the maximum span of the belt in the entire wheel train is taken as the test object, and a test mark is made at the middle position of the test belt.

[0025] Take the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com