Lacquering device for varnished wire

A technology of painting device and enameled wire, applied in the direction of insulating conductors/cables, etc., can solve the problems of poor wire painting quality, high production cost, waste of insulating paint, etc., to avoid waste, ensure paint quality, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

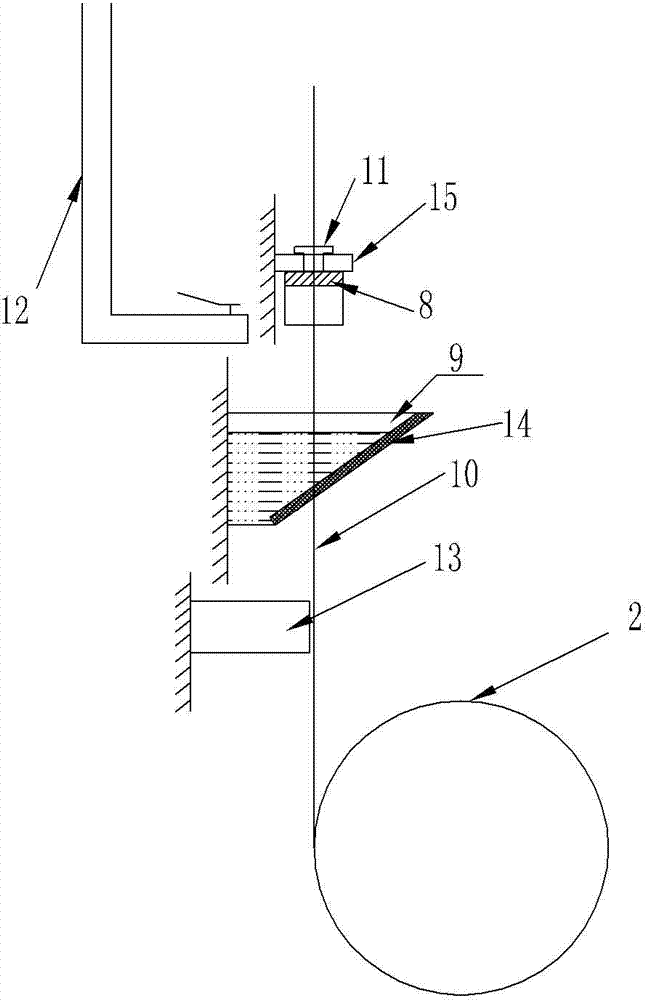

[0011] See figure 2 , the present invention includes a painting mold device, a paint vat 1 and a guide wheel 2 arranged from top to bottom, the paint vat 1 is a transparent cylindrical structure, the painting mold device is installed on the top of the paint vat 1, and the bottom of the paint vat 1 passes through the bottom cover 3 sealing, paint felt 7 is installed on the bottom cover 3. The painting mold device includes a mold base 4, a mold 5 and a mold cover 6. The mold base 4 is coaxially fixed on the top of the paint vat 1. The mold cover 6 fixes the mold 5 in the mold base 4. The mold cover 6 and the mold base 4 are threaded. Connection; the inner wall of the bottom cover 3 is threadedly connected with the outer wall of the bottom end of the paint vat 1, and the paint felt 7 pads are laid on the bottom cover 3.

[0012] When the painting device of the present invention is used to paint the wires, the wires 10 to be processed are conveyed vertically and continuously upw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap