Motor

A technology for motors and armatures, applied in the field of motors, can solve problems such as weakening of end cap strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

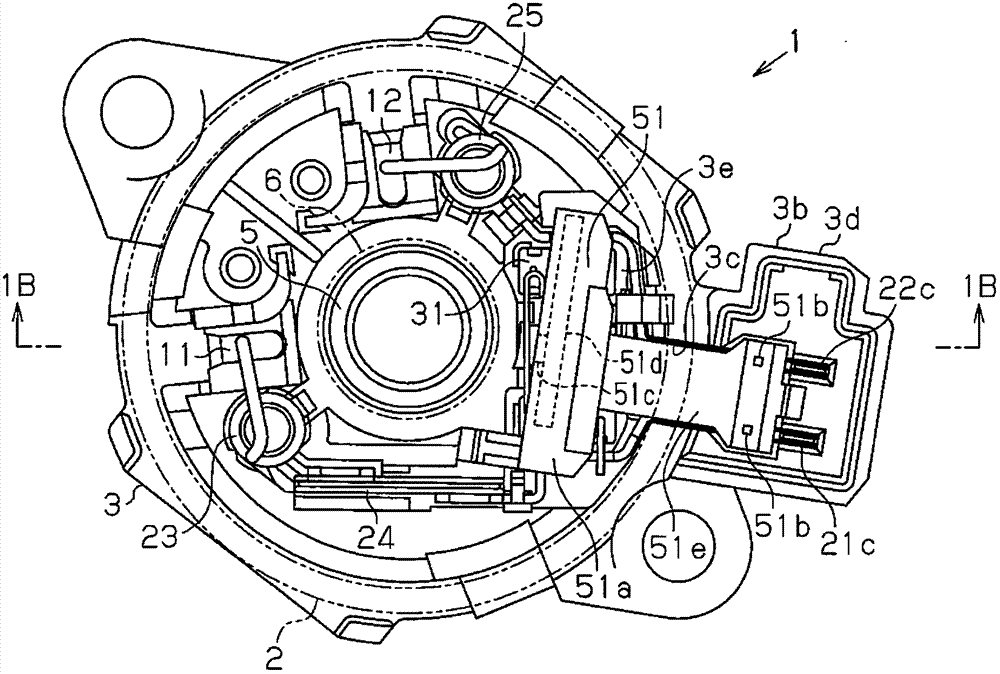

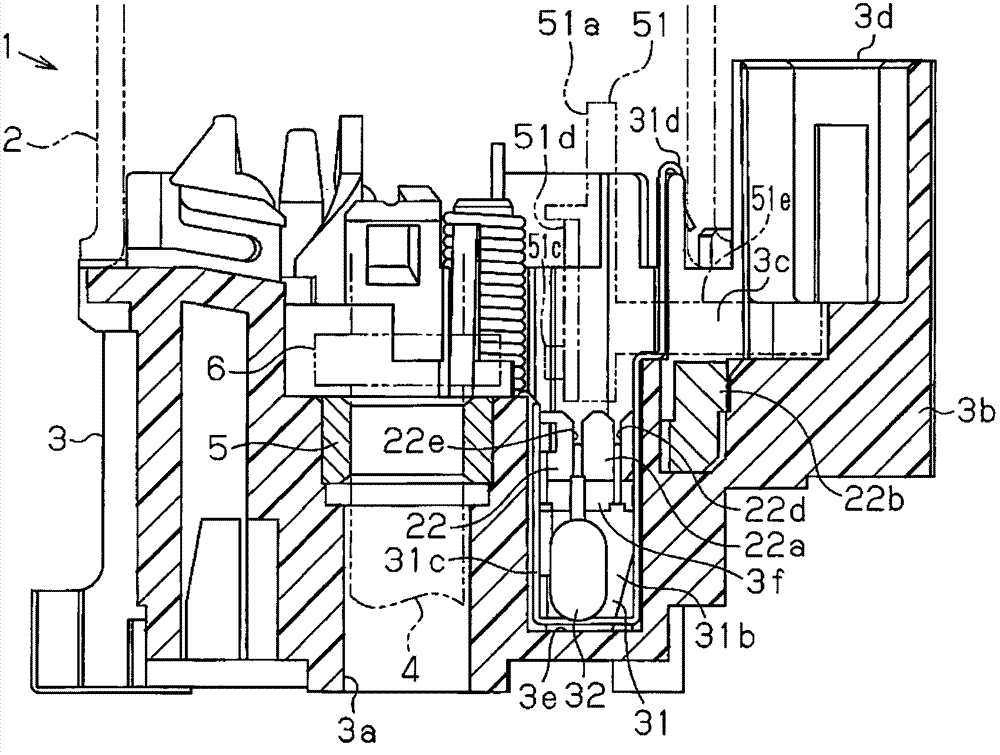

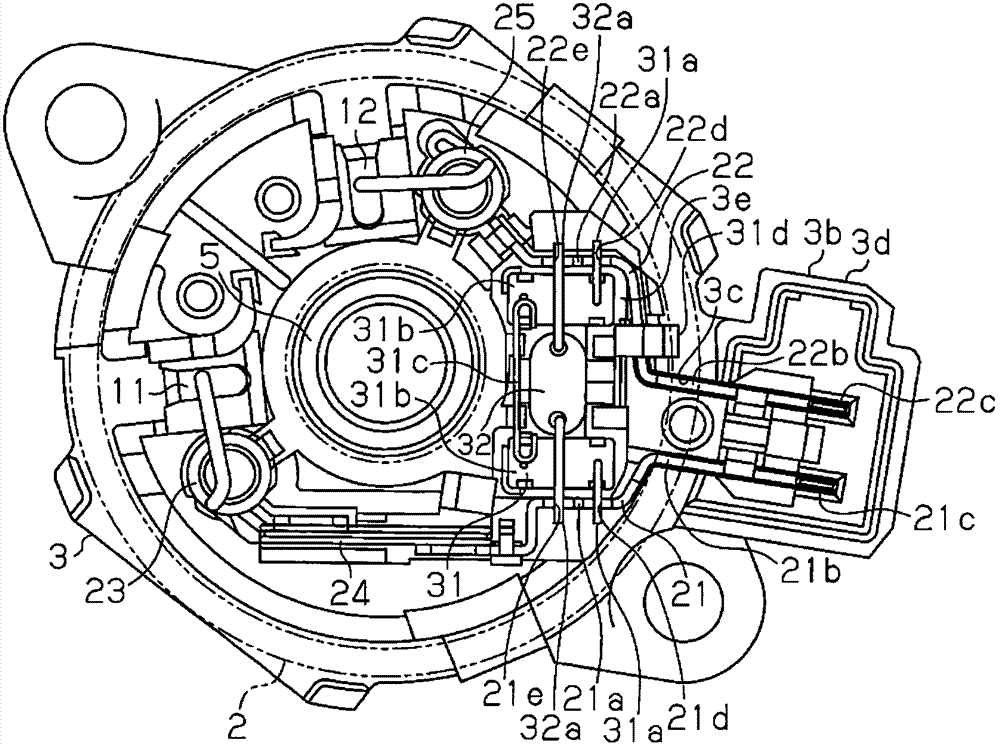

[0014] Hereinafter, an embodiment embodying the present invention will be described with reference to the drawings.

[0015] Such as Figure 1A as well as Figure 1B As shown, the motor 1 includes: a yoke 2 formed of a magnetic metal material into a substantially cylindrical shape having a bottom and an open end; and an end cover 3 fixed to substantially close the open end of the yoke 2 . A magnet (not shown) is fixed on the inner peripheral surface of the yoke 2 . An armature is accommodated in the yoke 2 . The rotating shaft 4 of the armature is rotatably supported by an unillustrated bearing and a bearing 5. The unillustrated bearing is held at the center of the bottom of the yoke 2, that is, at the center of the end face opposite to the open end. 5 is held on the bottom of the end cap 3. On the rotating shaft 4, in addition to the core on which the winding is wound, a commutator and a sensor magnet 6 are also fixed (refer to Figure 1B ). Such as Figure 1B As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com