Mounting rail for mounting and positioning a seal

A sealing device and slat technology, which is applied in the sealing device, transportation and packaging, engine sealing, etc., can solve problems such as uneven pressure distribution, spring tongue material fatigue, etc., and achieve the effect of increasing the replacement interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

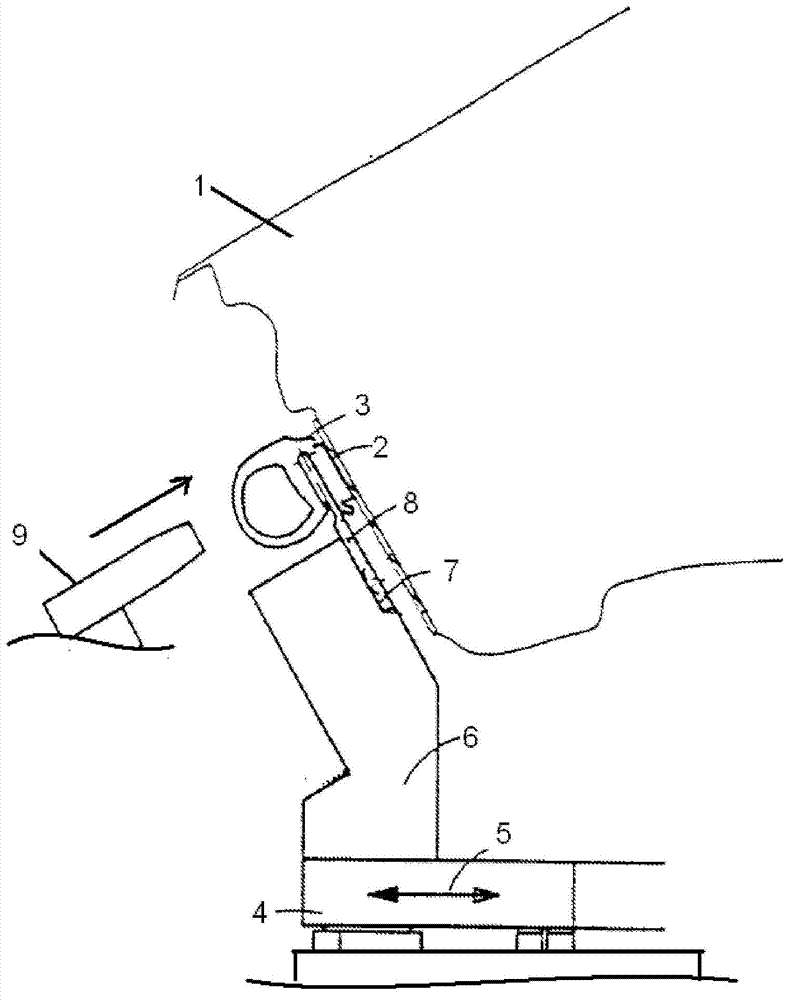

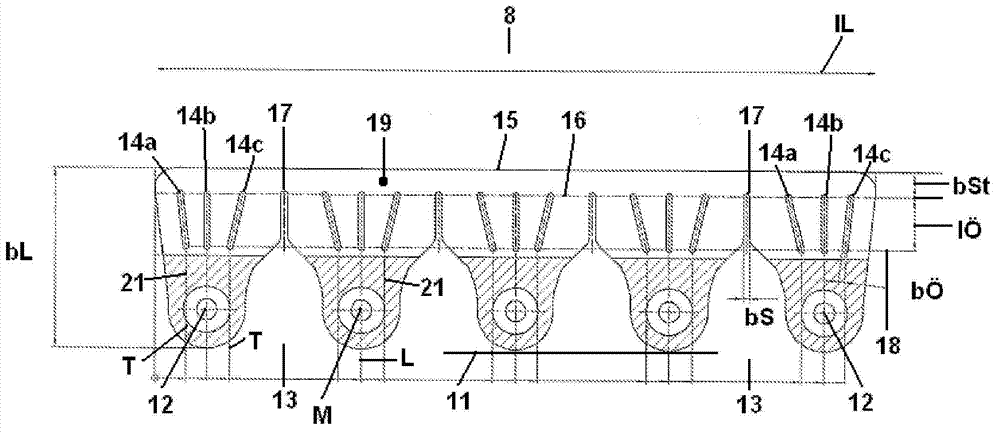

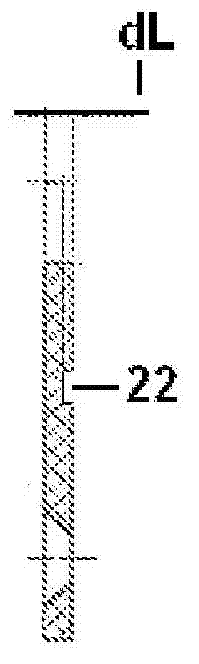

[0022] figure 1 The middle section shows a vehicle door ( 1 ) with a surrounding adhesive surface ( 2 ) to which the seal ( 3 ) is to be attached. This takes place by means of an application device, to which belongs a large number of mobile units ( 4 ) arranged next to each other and following the contour of the vehicle door. Each displacement unit ( 4 ) is movable back and forth in the direction of the double arrow ( 5 ), wherein the direction of movement of each displacement unit ( 4 ) is oriented relative to the respectively associated section of the door contour or adhesive surface ( 2 ). A profile element (6) with a profile surface (7) is attached to the displacement unit (4). A retaining strip ( 8 ) is screwed onto the contoured surface ( 7 ), the retaining strip ( 8 ) protrudes beyond the contoured surface ( 7 ) and the seal ( 3 ) is pushed onto the free edge of the retaining strip.

[0023] The seal ( 3 ) is applied by plugging it onto the retaining strip ( 8 ). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com