Process for hot rolling steel strips and hot rolling train

A technology of steel strips and trains, applied in heat treatment furnaces, metal rolling, heat treatment equipment, etc., can solve problems such as inability to ensure the cooling of steel strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

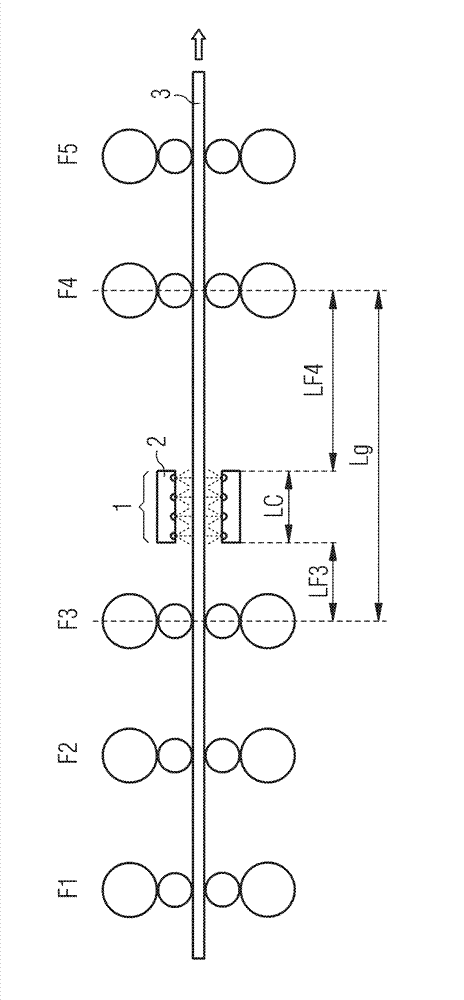

[0057] The steel strip 3 enters the hot rolling train consisting of rolling stands F1 to F5 at an input temperature of less than 1050° C., preferably less than 1020° C., for example from the roughing mill train connected to the continuous casting plant on the left in the drawing. The temperature of the steel strip 3 refers to the average value of the temperatures obtained by taking the average value on the cross section of the steel strip. In the first three rolling stands F1 to F3 the steel strip 5 is rolled in the austenitic state, leaving the rolling stand F3 with a strip thickness of generally less than 3 mm.

[0058] Here, the cooling section 1 has a plurality of nozzles 2 on both sides of the belt, which nozzles are arranged in at least one nozzle row per belt side, and the cooling section 1 has a length Lc of at least 350 mm. The distance LF3 between the third rolling stand F3 and the beginning of the cooling section 1 is here only a fraction of the distance LF4 between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com