Power generating apparatus of renewable energy type

一种发电装置、再生能型的技术,应用在风能发电、风力发电机组件、安装/支撑风力发动机的配置等方向,能够解决发电机热损失变大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

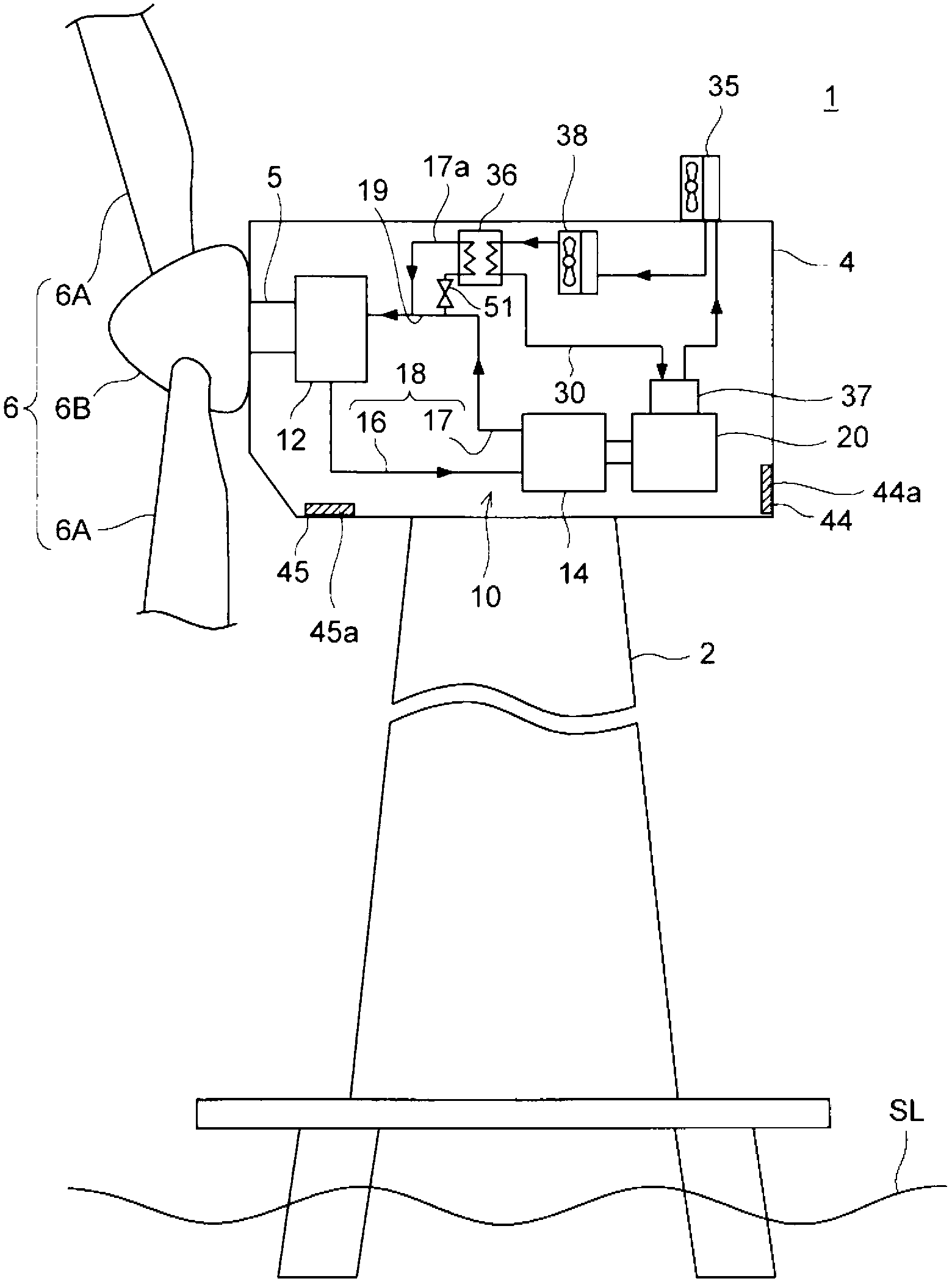

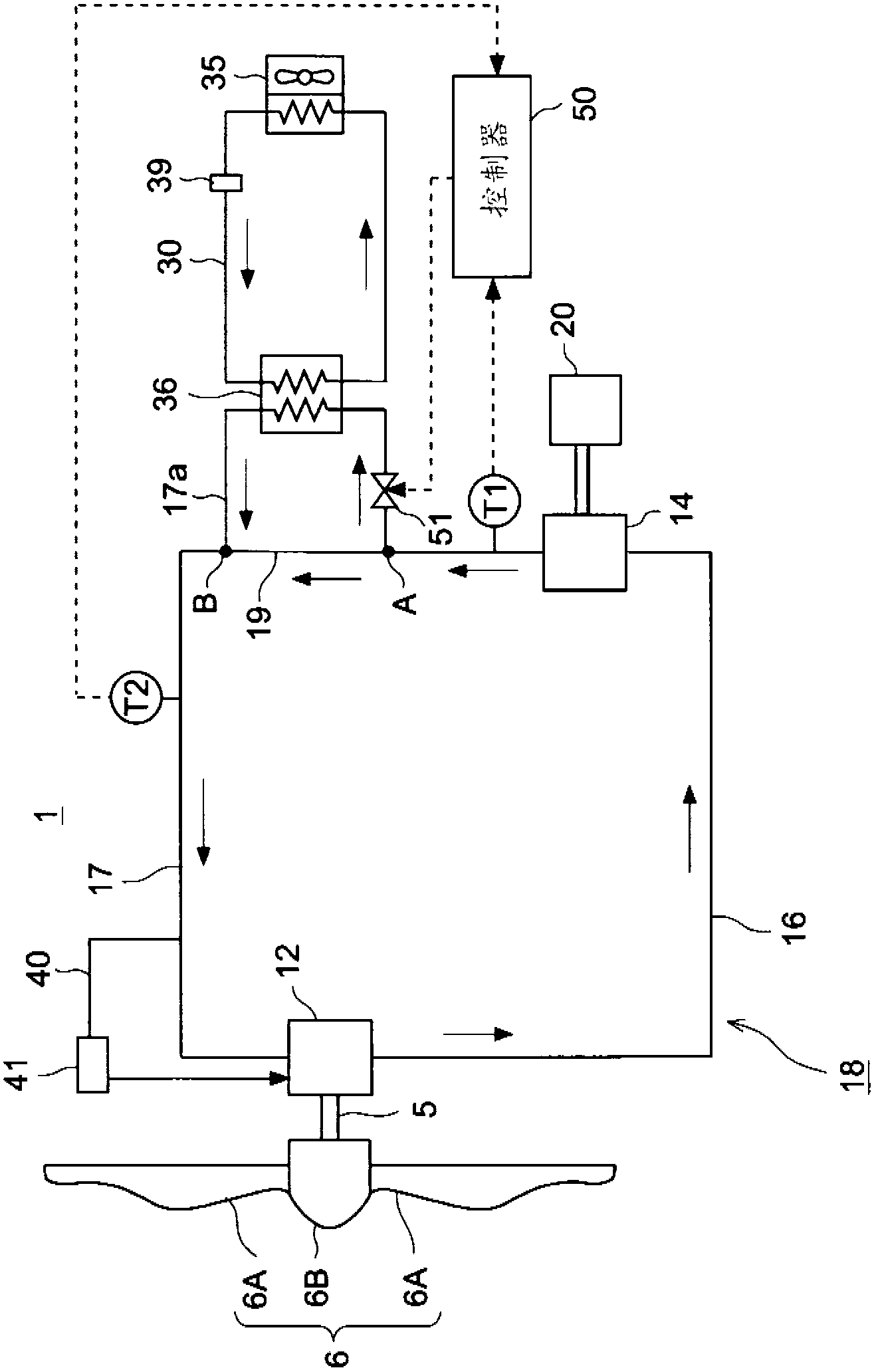

[0058] Reference figure 1 with figure 2 The wind power generation device according to the first embodiment of the present invention will be described. here, figure 1 Is a diagram showing the overall structure of the wind power generation device of the first embodiment, figure 2 It is a diagram showing an example of the structure of the oil pipeline and the cooling medium pipeline.

[0059] Such as figure 1 As shown, the wind power generator 1 mainly includes a tower 2, a nacelle 4 supported by the tower 2, and a rotating body 6 that rotates using energy of wind.

[0060] figure 1 Here, the offshore wind power generator installed on the sea surface SL is exemplified as the wind power generator 1, but the wind power generator 1 may be installed on land.

[0061] The rotating body 6 includes at least one (for example, three) blades 6A and a hub 6B that supports the blades 6A. The hub 6B is connected to the main shaft 5 housed in the nacelle 4. Therefore, when the blade 6A receives w...

no. 2 example )

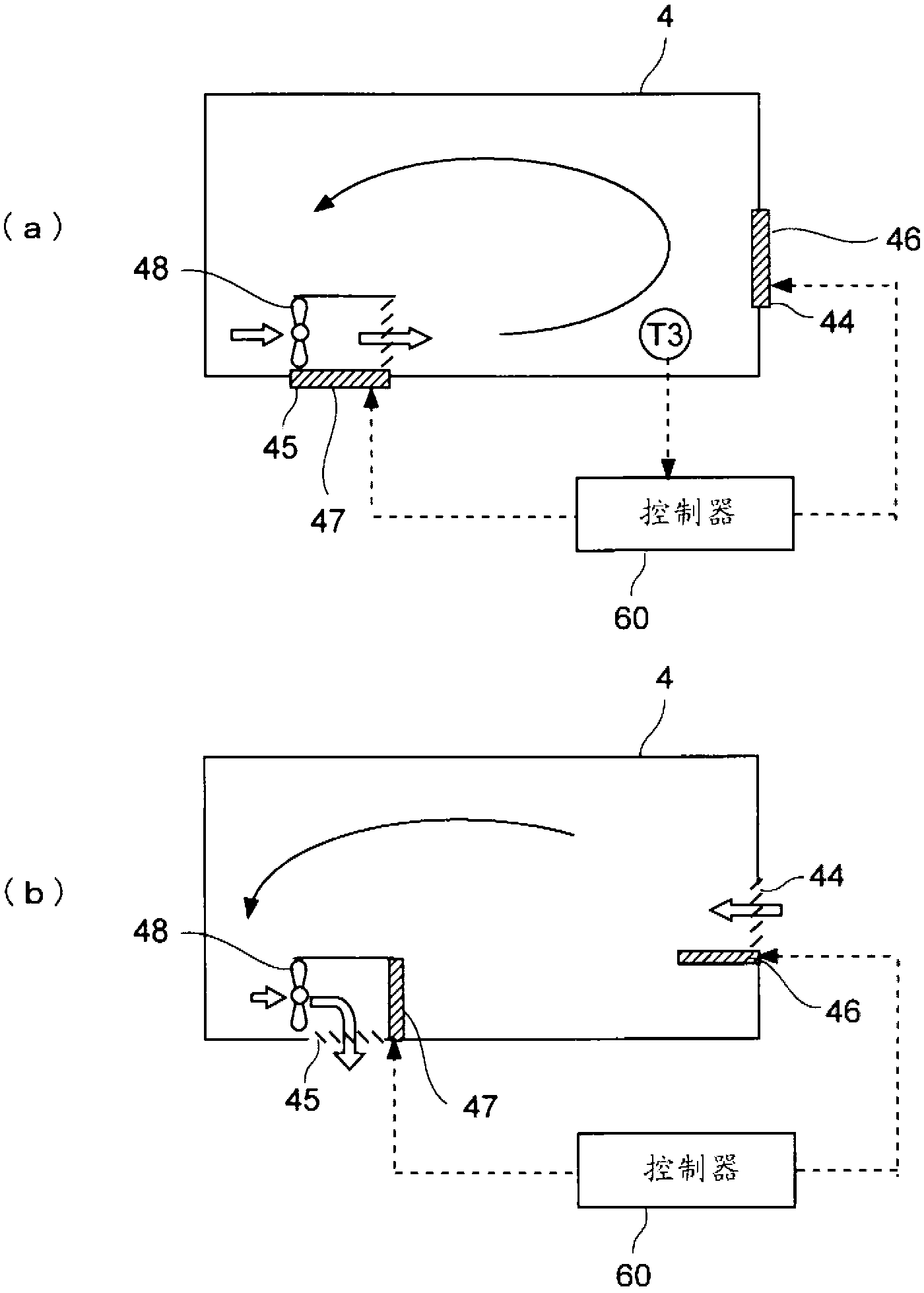

[0103] Next, the wind power generator of the second embodiment will be described. The wind power generator of this embodiment has the same structure as the wind power generator 1 of the first embodiment already described, except for the cooling mechanism in the transformer chamber 72. Therefore, the components common to the first embodiment are given the same reference numerals, and their description is omitted, and the description will focus on the parts different from the first embodiment.

[0104] Such as Figure 7 As shown, the wind power generator 1 includes a transformer room cooler 91 that cools the transformer room 72. The transformer compartment cooler 91 is connected to a cooling medium line 30 that supplies a cooling medium to the oil cooler 36. In the same figure, the cooling medium line 30 on the side of the oil cooler 36 and the cooling medium line 30' on the side of the transformer chamber 72 are connected to the heat exchanger 35 for heat exchange between the env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com