Quick-release water dropper device for dropping soft capsule machine

A technology of soft capsules and drippers, applied in capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve problems such as messy production sites, cumbersome operations, and non-compliance with GMP requirements, and achieve the effects of improving productivity and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

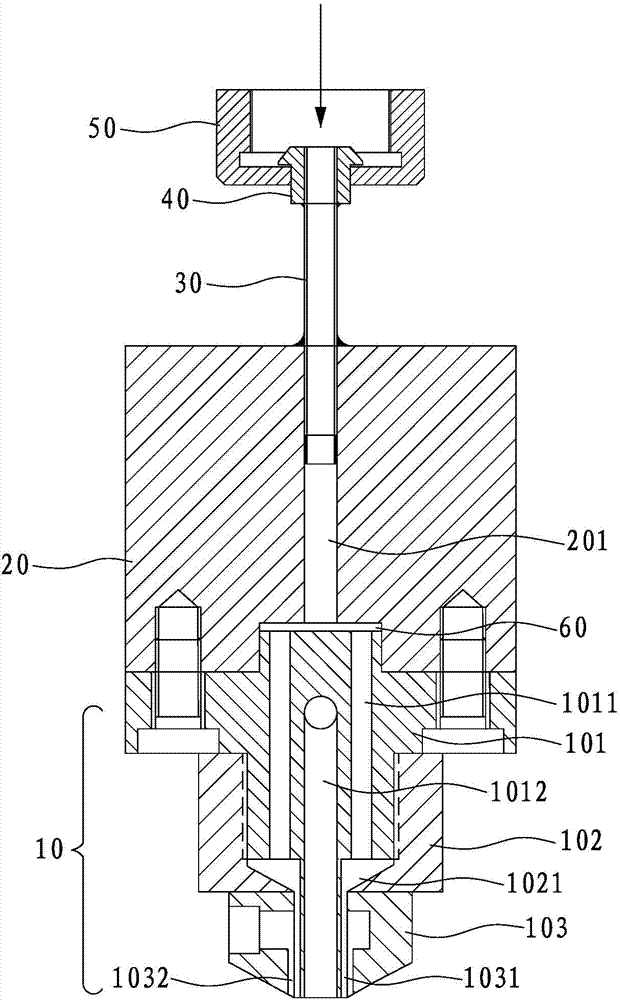

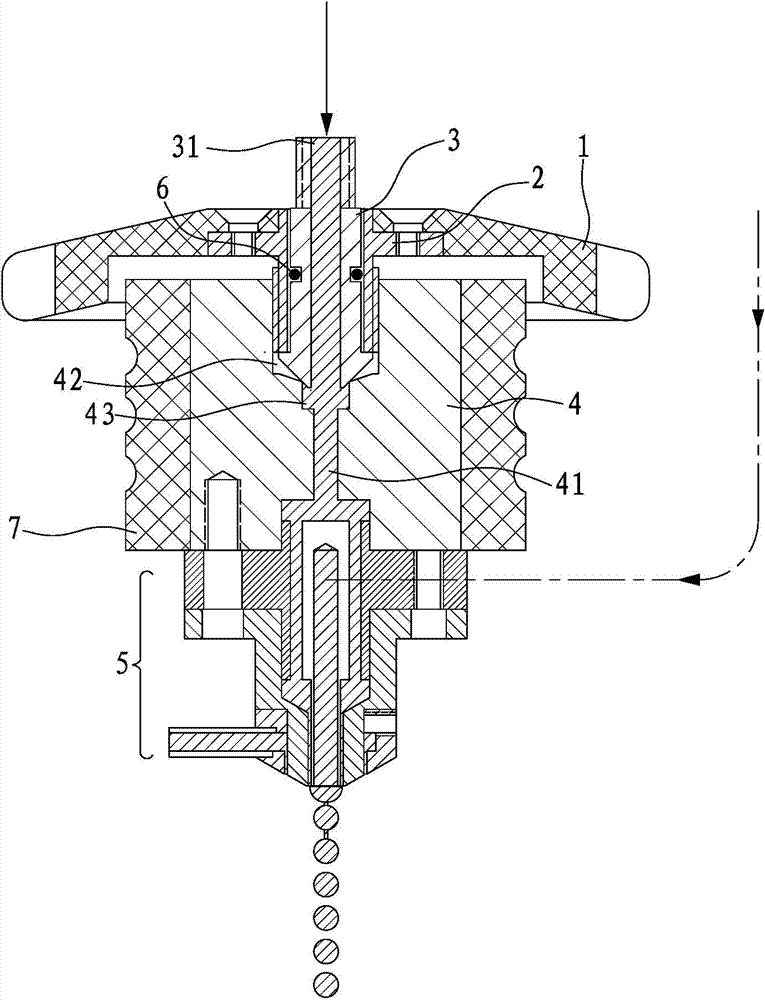

[0031] refer to figure 2 As shown, the invention discloses a quick-release dripper device for a soft capsule making machine, including a fixed mounting plate 1, a cylinder connector 2, a pump connector 3 connected to the pump, a cylinder 4 and a drip nozzle 5 .

[0032] The fixed plate 1 is mounted on the cylinder connector 2 , the cylinder connector 2 is screwed on the pump body connector 3 , and the pump body connector 3 forms a glue channel 31 .

[0033] The cylinder 4 is screwed on the cylinder connector 2 and forms a through groove 41 communicating with the glue channel 31 of the pump connector 3 .

[0034] The drip nozzle 5 is installed at the lower end of the cylinder body 4, and the structure of the drip nozzle 5 and its installation method with the cylinder body 4 are the same as those of the prior art, and will not be repeated he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com