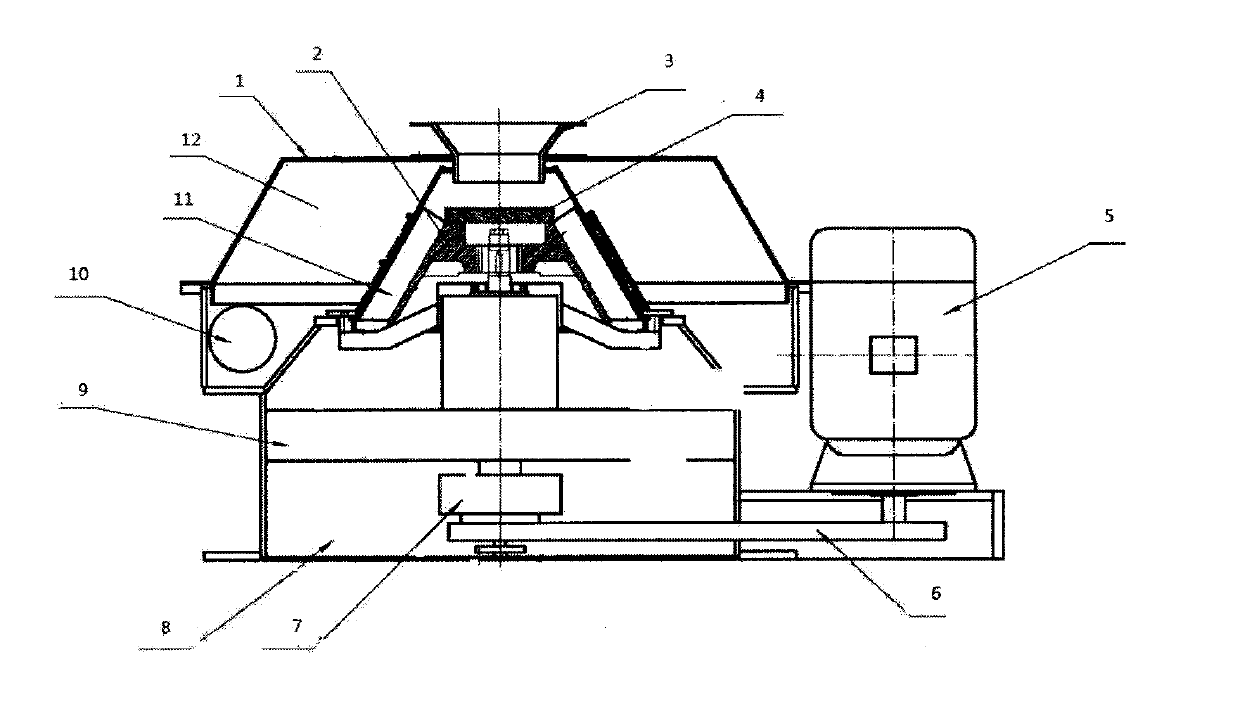

Equipment and method for spin-drying oil-based drilling fluid wastes

An oil-based drilling fluid and waste technology, which is applied in the field of drilling fluid waste drying and treatment equipment, can solve problems such as waste pollution, and achieve the effects of low energy consumption, cost reduction and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

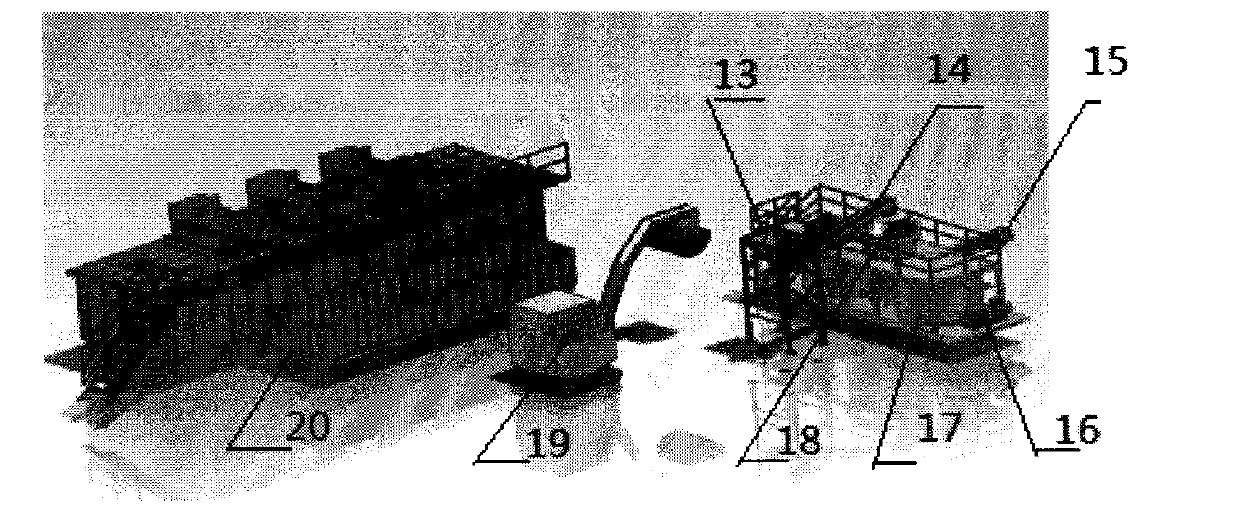

[0023] a. Check the condition of each equipment (all parts are not loose, the lubrication is normal, and the circuit is intact). After it is completely normal, it is ready to start. (Start the program, start in sequence: drying machine → 2# screw conveyor → 1# screw conveyor) , for 5-10 minutes test run;

[0024] b. When the drying machine is turned on, first turn on the oil pump, and then turn on the main engine; when the drying machine is turned off, first turn off the main engine, and then turn off the oil pump;

[0025] c. Stop the processing procedure and turn off in turn: 1# screw propeller → 2# screw pusher → spin dryer;

[0026] d. When the liquid phase tank exceeds the calibrated liquid level, turn on the high-speed centrifuge, turn on in turn: auxiliary machine → main machine → liquid supply pump; turn off the centrifuge, turn off in order: liquid supply pump → main machine → auxiliary machine.

[0027] From July 16th to July 26th, the accumulated cuttings processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com