Improved automatic paper cone coiling machine set for tube coiling mechanism

An improved and fully automatic technology, which is applied in the direction of paperboard winding products, can solve the problems of high cost of rolling tubes and low utilization rate of raw paper, and achieve the effects of stable rolling process, low cost and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

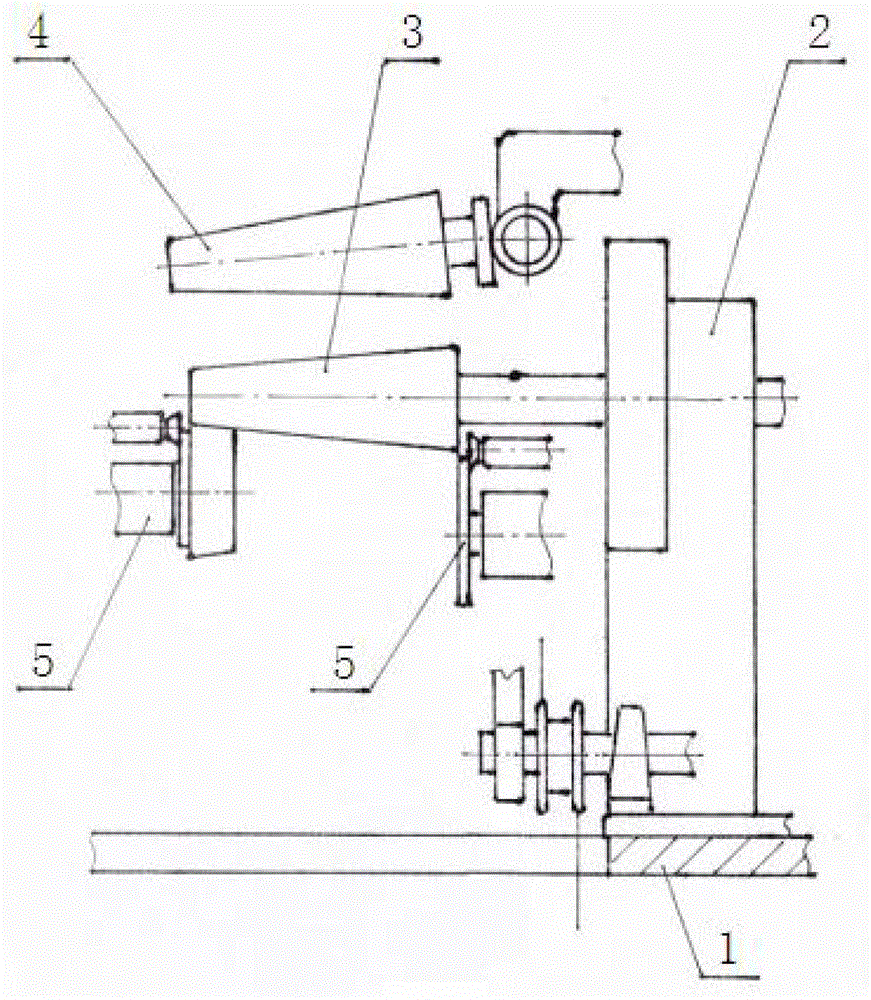

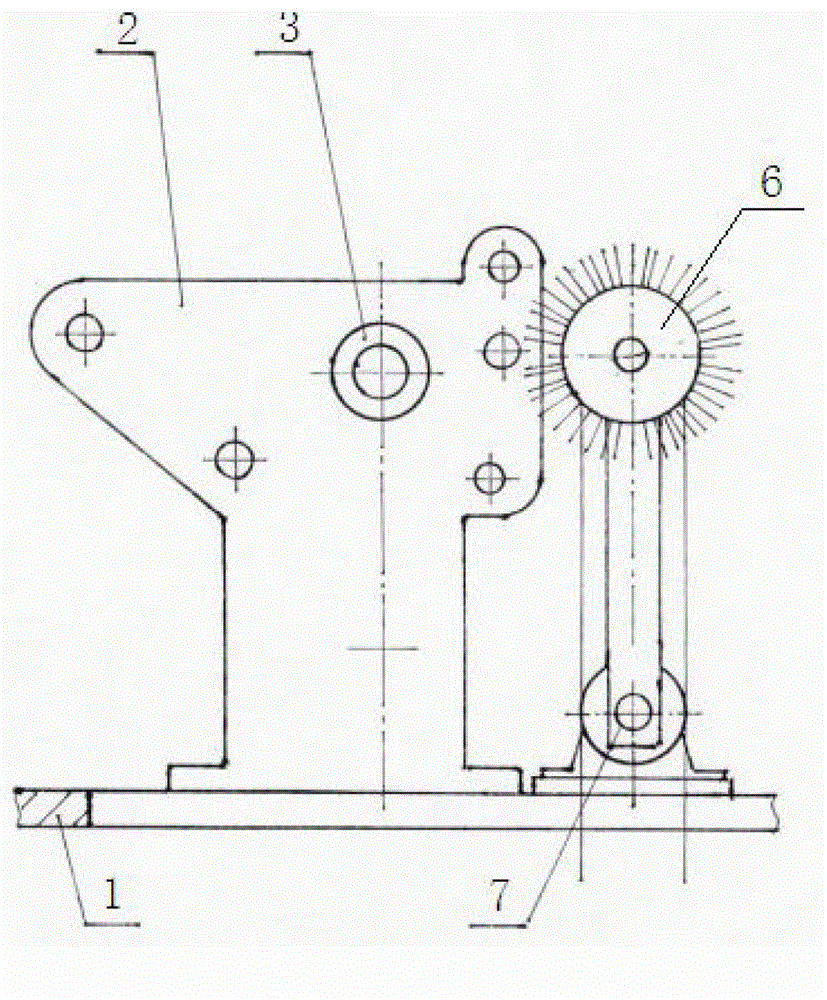

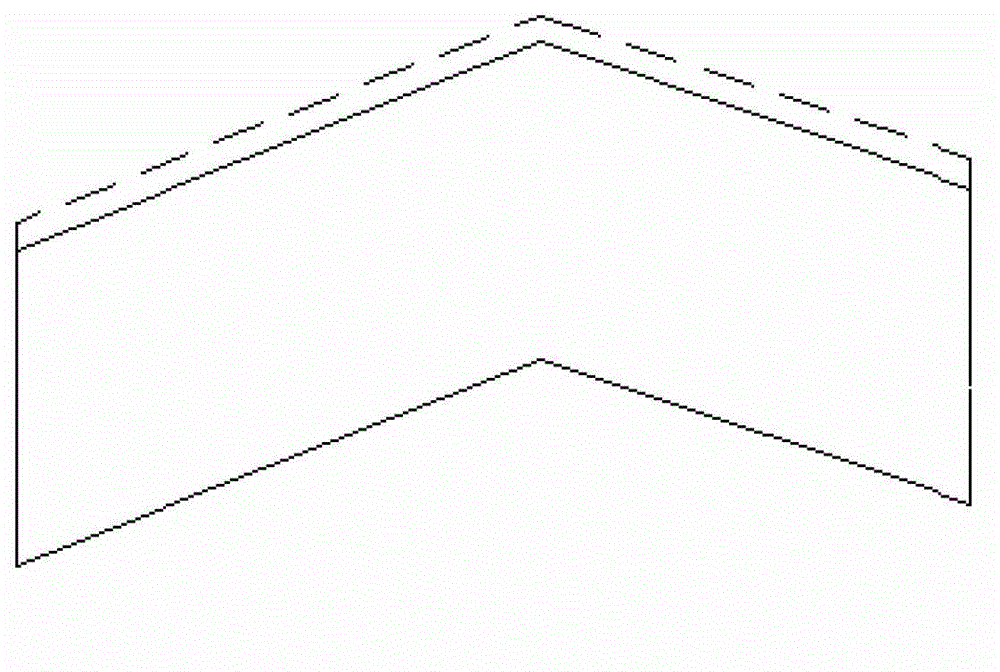

[0017] Such as Figure 1~3 Shown, a pagoda paper tube automatic coiling unit with an improved tube rolling mechanism, including an operating table, a frame fixed on the operating table, a conical tube rolling mold on the frame, a floating Roller mechanism, shearing mechanism and brush mechanism, the tapered tube rolling mold is horizontally fixed on the frame, and rotates under the drive of the motor; the two ends of the tapered tube rolling mold are respectively equippe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap