Drying-out-free type die bonding glue and preparation method thereof

A crystal-bonding adhesive and no-baking technology, which is applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of affecting the bonding process, polluting the PCB board, and prone to tailing, etc., achieving long storage period, Good adhesive performance and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

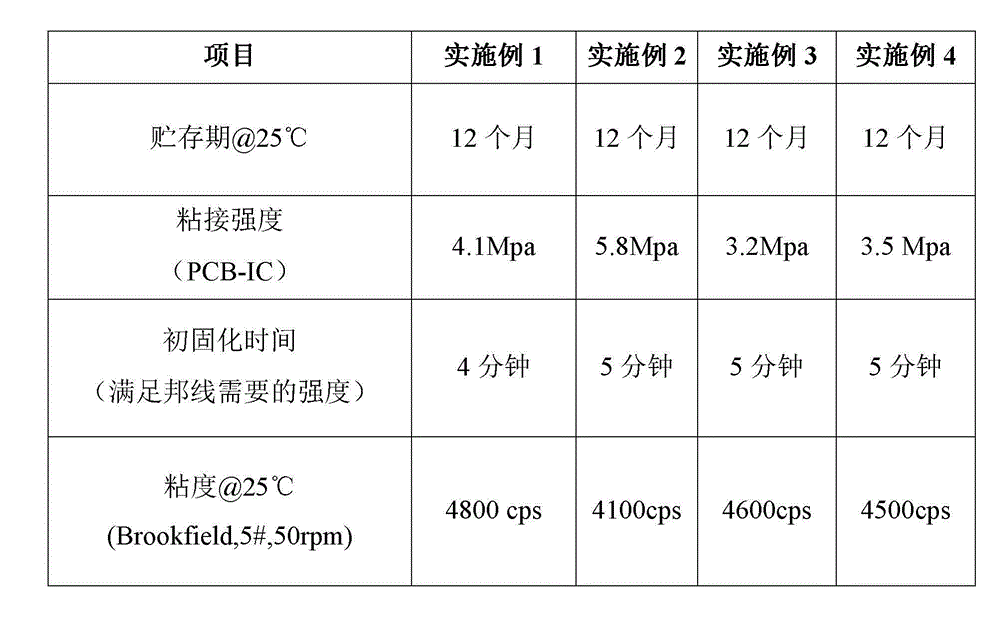

Examples

Embodiment 1

[0021] The preparation method of this no-baking type crystal-bonding glue comprises the following steps in sequence:

[0022] (1) Take 50Kg (kilogram) of bisphenol A epoxy diacrylate (both bisphenol A epoxy diacrylate with a viscosity of 500000cps and a hydrolyzable chlorine content of 100ppm), 5Kg of reactive diluent (both are methacrylic acid hydroxyl ethyl ester), 3Kg o-sulfobenzimide, 0.5Kg accelerator (both acetophenylhydrazine), 0.15Kg stabilizer (including hydroquinone 0.05Kg, edetate tetrasodium 0.1Kg), and Add to the first reaction vessel that is clean, dry and has a circulating water jacket; then run the circulating water jacket of the first reaction vessel (in this step, the internal water temperature of the circulating water jacket of the first reaction vessel is 75° C.), And stirring the materials in the first reaction vessel (in this step, the stirring speed is 1500 rpm, and the stirring time is 40 minutes); after the stirring is completed, the first semi-finishe...

Embodiment 2

[0027] The preparation method of this no-baking type crystal-bonding glue comprises the following steps in sequence:

[0028](1) Take 50Kg of bisphenol A epoxy diacrylate (both bisphenol A epoxy diacrylate with a viscosity of 700000cps and a hydrolyzable chlorine content of 300ppm), 15Kg of reactive diluent (including 5Kg of hydroxyethyl methacrylate , hydroxypropyl methacrylate 10Kg), 5Kg o-sulfobenzimide, 0.1Kg accelerator (both acetophenhydrazine), 0.11Kg stabilizer (including hydroquinone 0.06Kg, ethylenediamine diacetic acid Tetrasodium 0.05Kg), and join in the first reaction vessel that cleans, dry and have circulating water jacket; Then run the circulating water jacket of the first reaction vessel (in this step, when the circulating water jacket of the first reaction vessel is running, its interior The water temperature is 70°C), and the materials in the first reaction container are stirred (in this step, the stirring speed is 1000 rpm, and the stirring time is 60 minut...

Embodiment 3

[0033] The preparation method of this no-baking type crystal-bonding glue comprises the following steps in sequence:

[0034] (1) Take 50Kg bisphenol A epoxy diacrylate (both bisphenol A epoxy diacrylate with a viscosity of 800000cps and a hydrolyzable chlorine content of 100ppm), 8Kg reactive diluent (both are hydroxypropyl methacrylate ), 1Kg o-sulfobenzimide, 2Kg accelerator (both benzohydrazide), 1Kg stabilizer (both disodium ethylenediaminetetraacetate), and added to a clean, dry and circulating water jacket In the first reaction vessel; then run the circulating water jacket of the first reaction vessel (in this step, the internal water temperature of the circulating water jacket of the first reaction vessel is 80° C.), and stir the materials in the first reaction vessel (In this step, the stirring speed is 1500 rpm, and the stirring time is 50 minutes); after the stirring is completed, the first semi-finished rubber material is obtained;

[0035] (2) 50Kg bisphenol A ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com