Master control multichannel conversion valve

A multi-way reversing valve, one-way valve technology, applied in the direction of fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the principle and practical degree to explore the oil replenishment method and other problems, to eliminate hidden troubles, leakage Low volume, high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

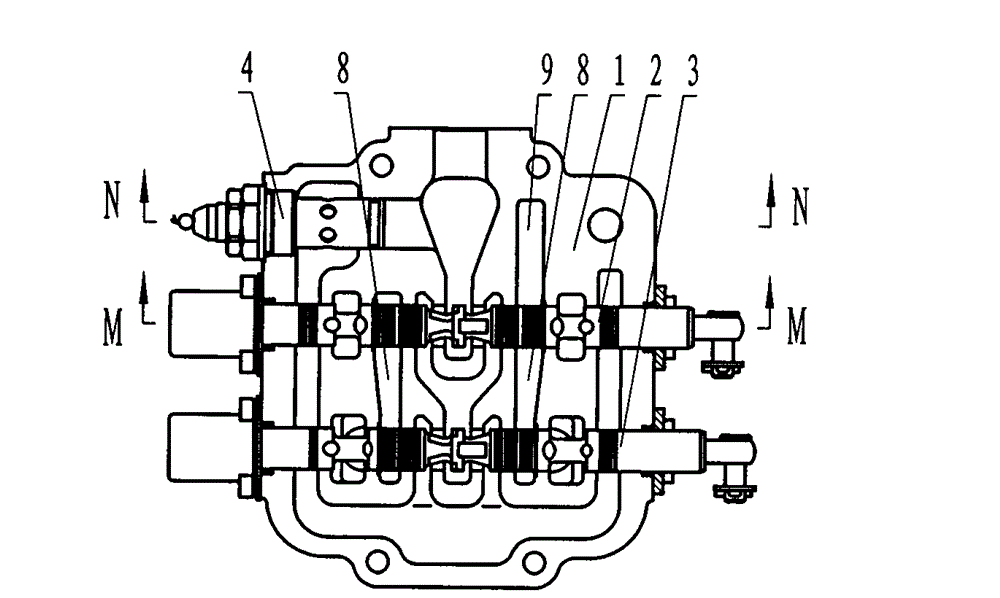

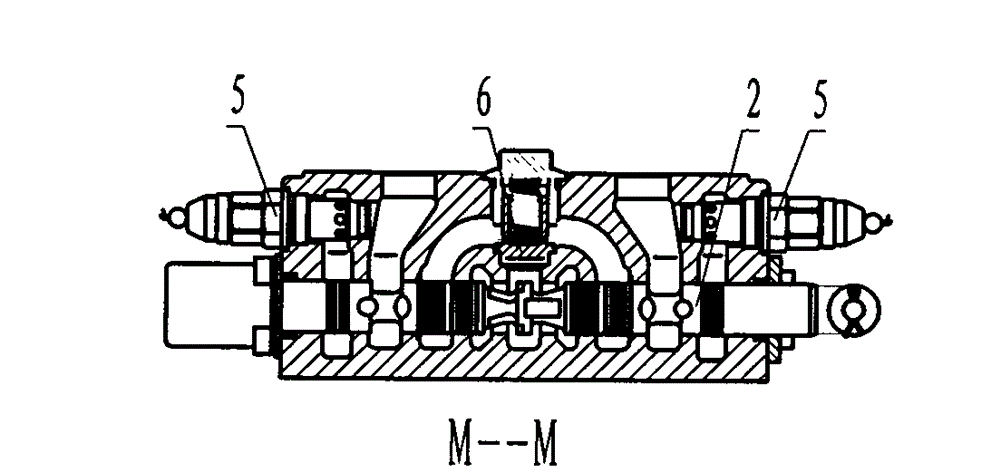

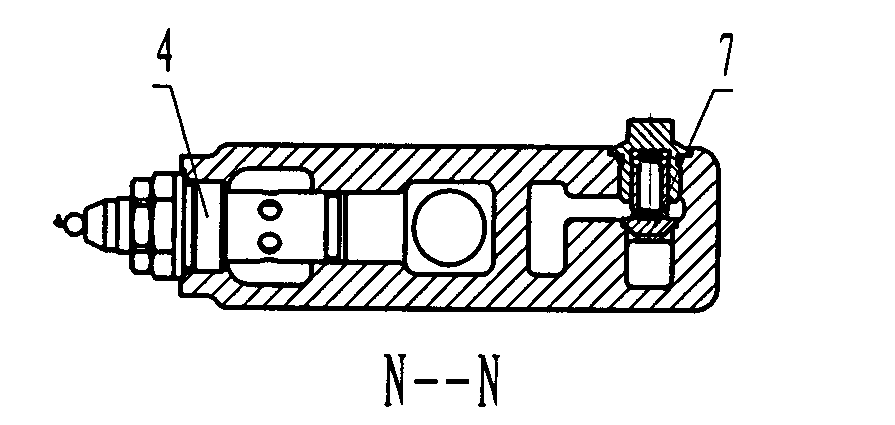

[0012] The structure and use of the present invention will be described in detail below in conjunction with the embodiments given in the accompanying drawings. Referring to the accompanying drawings, this kind of master control multi-way reversing valve includes an integral valve body (1), bucket valve stem (2), boom valve stem (3), main safety valve (4), overload oil supply valve (5), master control one-way valve (6), master control oil filling valve (7) etc. The integral valve body (1) has two-sided master control oil passages (8) and master control replenishment oil passages (9) that communicate with each other. In the disclosed design, the one-way valve oil passages and the replenishment valve oil passages are designed to be two, three or even several. The above-mentioned oil passage is simplified, the wall thickness of the valve body is more uniform, and casting defects such as trachoma, shrinkage cavity, and looseness are avoided.

[0013] In the integral valve body (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com