Freon-sewage heat exchanger

A freon and heat exchanger technology, which is applied in the field of freon-sewage heat exchangers, can solve problems such as technical difficulty and not well solved, and achieve the effects of reducing initial investment, improving efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

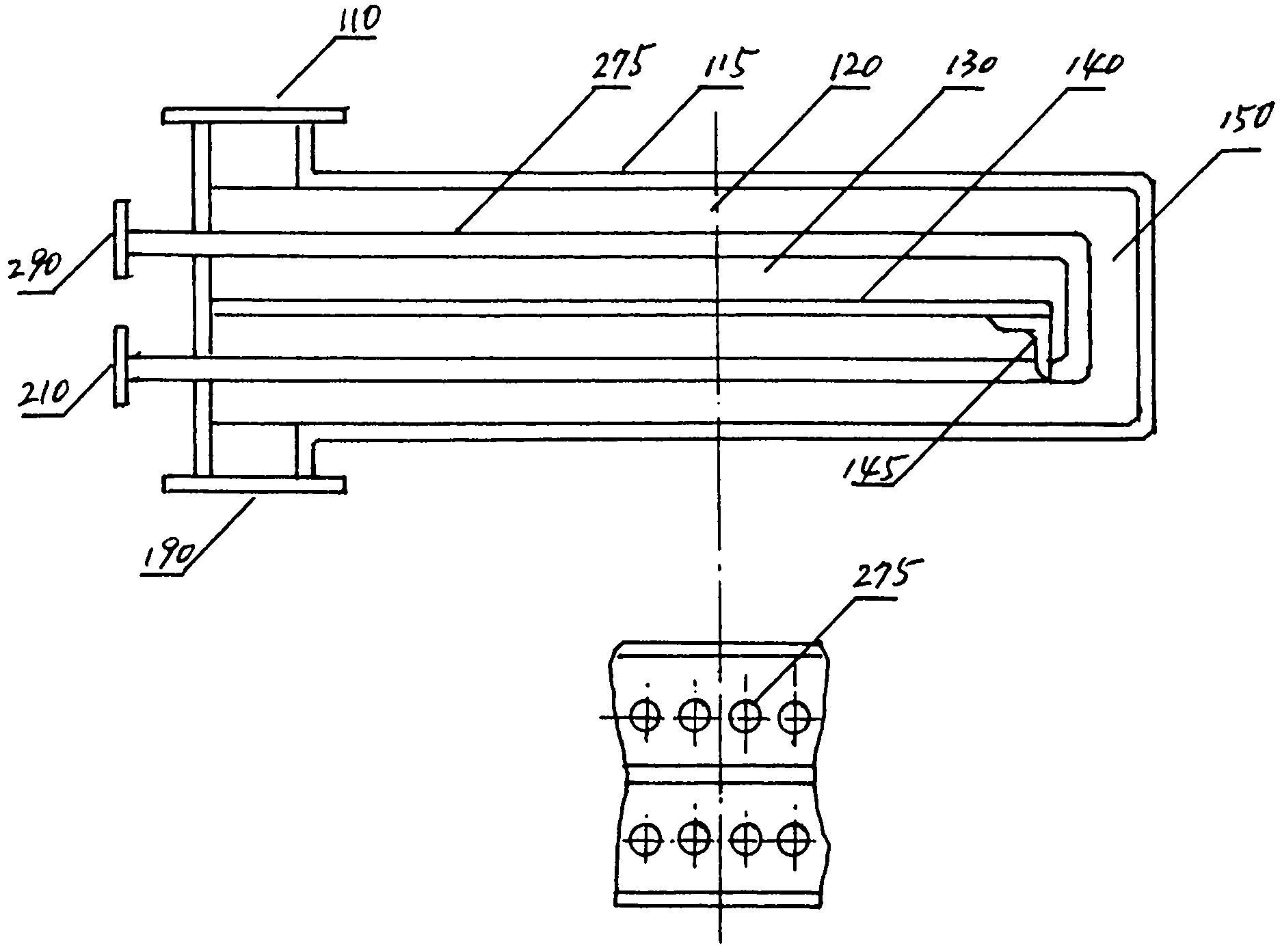

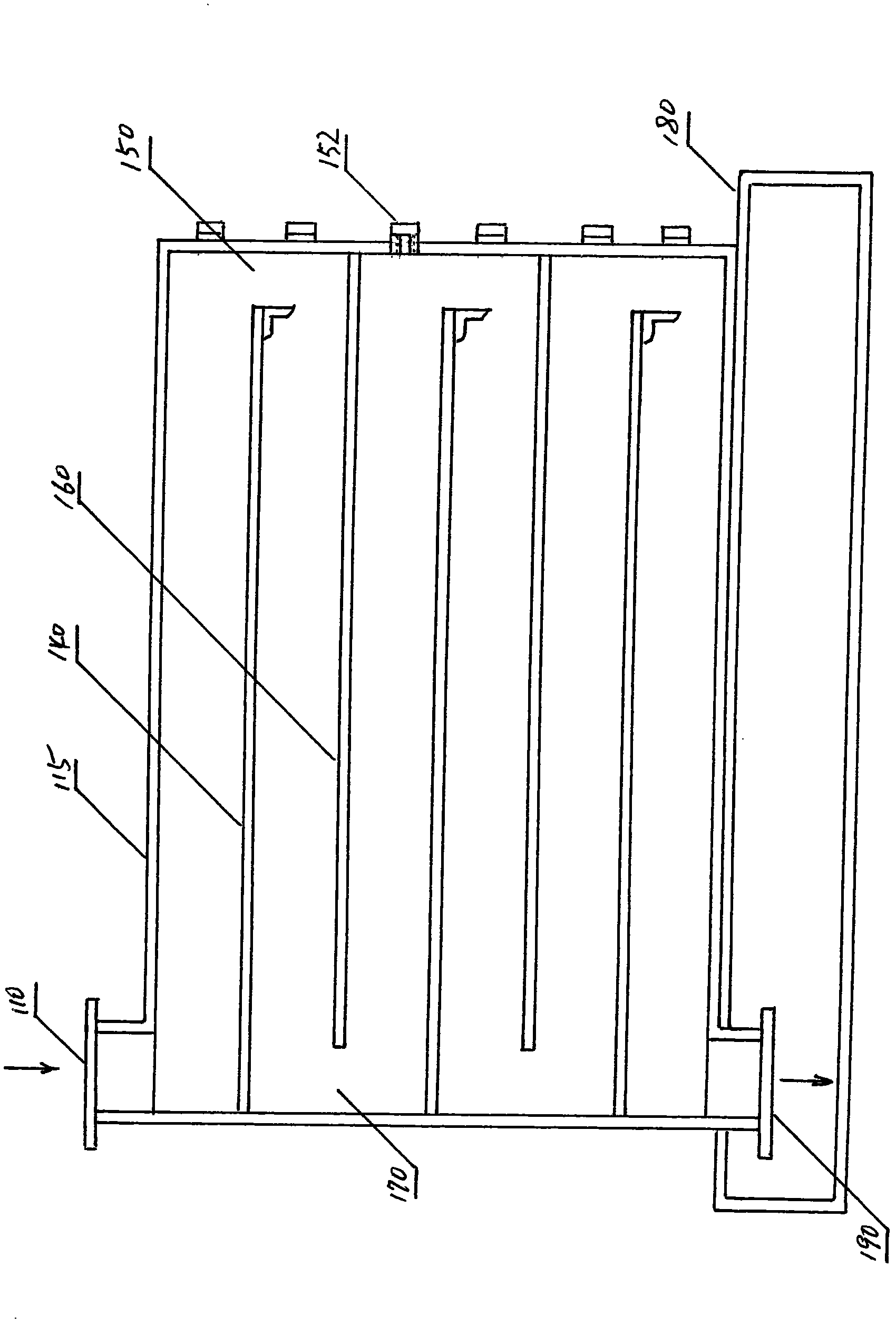

[0044] figure 1 The basic principle diagram of the embodiment of the Freon-sewage heat exchanger of the present invention is given.

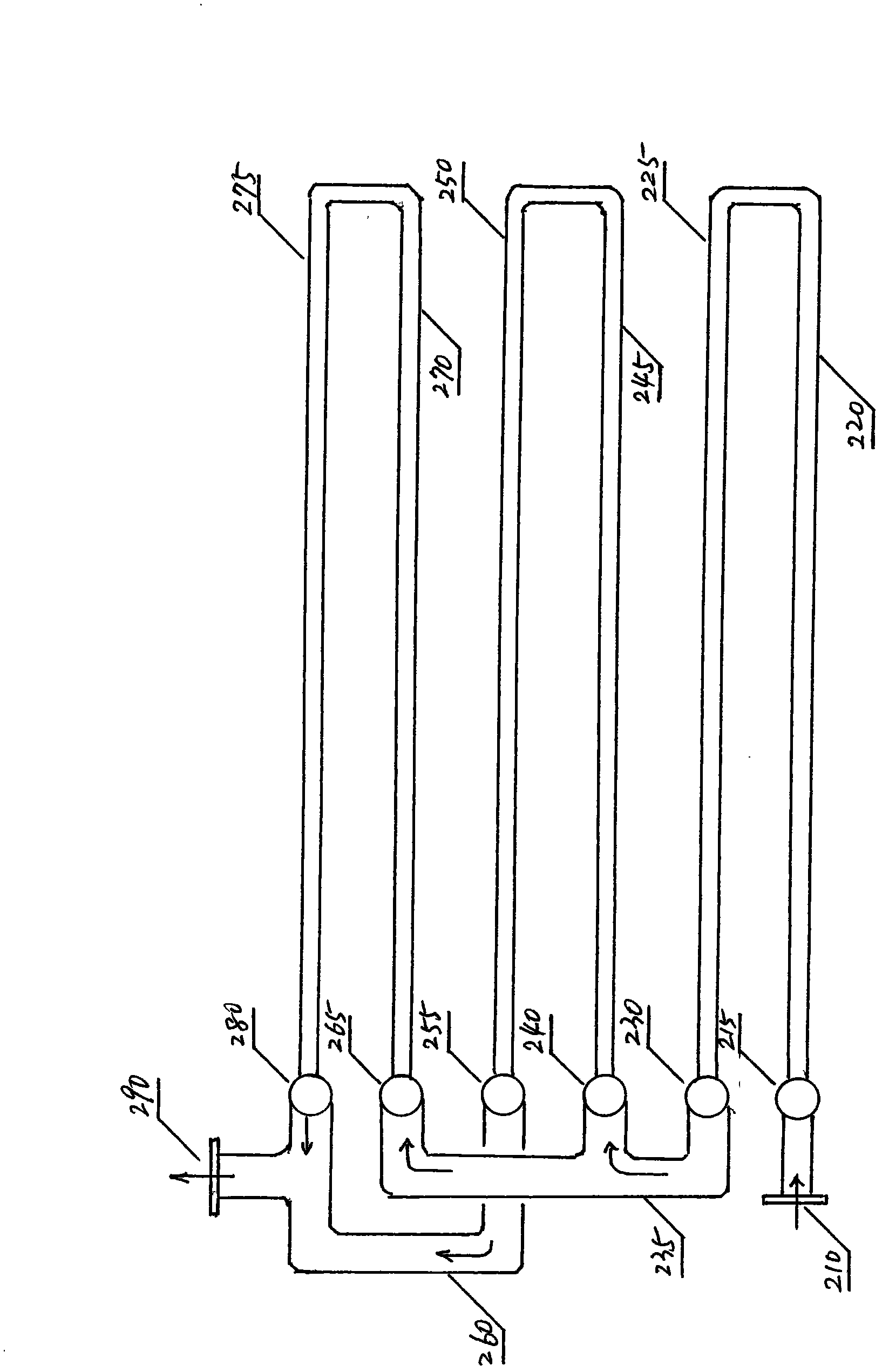

[0045] The Freon-sewage heat exchanger embodiment of the present invention is a shell-and-tube heat exchanger, and the box body 115 is the shell of the heat exchanger, which includes six panels of the box-shaped heat exchanger, up, down, left, right, front, back. As an evaporator, the sewage enters the sewage pipe 125 of the heat exchanger from the sewage inlet 110 above, and Freon flows from bottom to top in the heat transfer pipe 275, and the sewage flows outside the heat transfer pipe 275 and in the box body 115 from above. flow down.

[0046] The heat transfer pipe 275 is arranged in the sewage flow channel, and the axis of the heat transfer pipe is parallel to the flow direction of the sewage. The heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com