Phase array ultrasonic detecting device and method for solid axle

An ultrasonic testing and phased array technology, which is applied in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

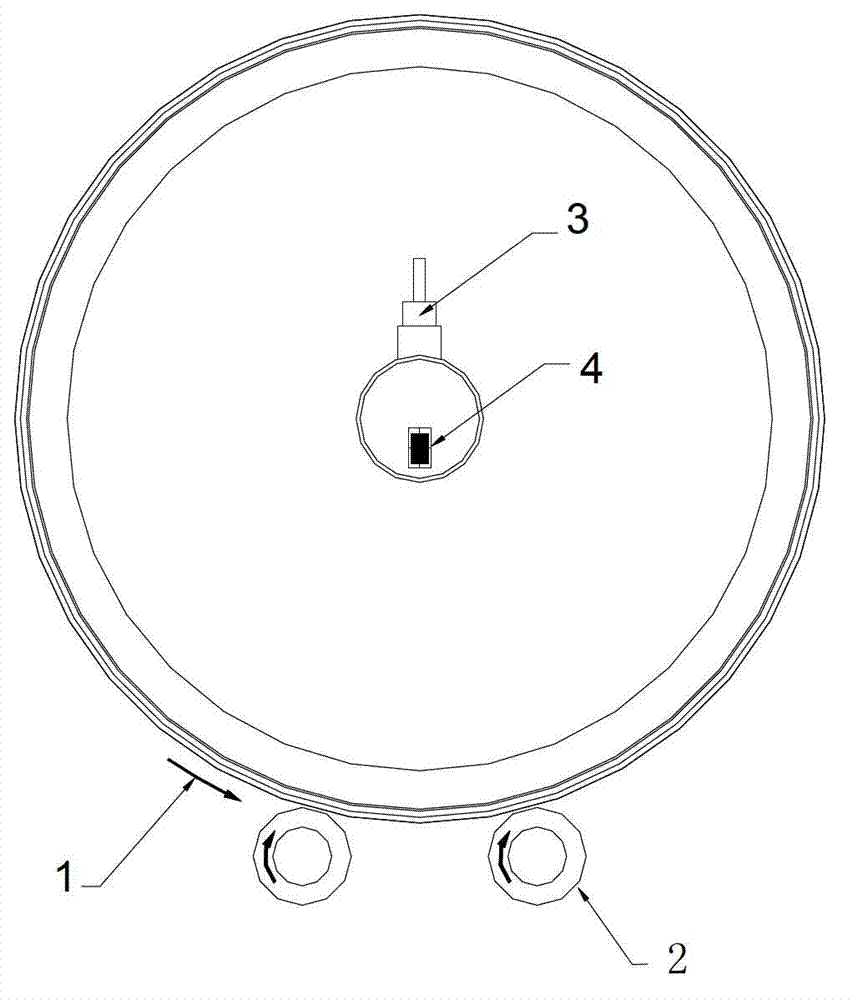

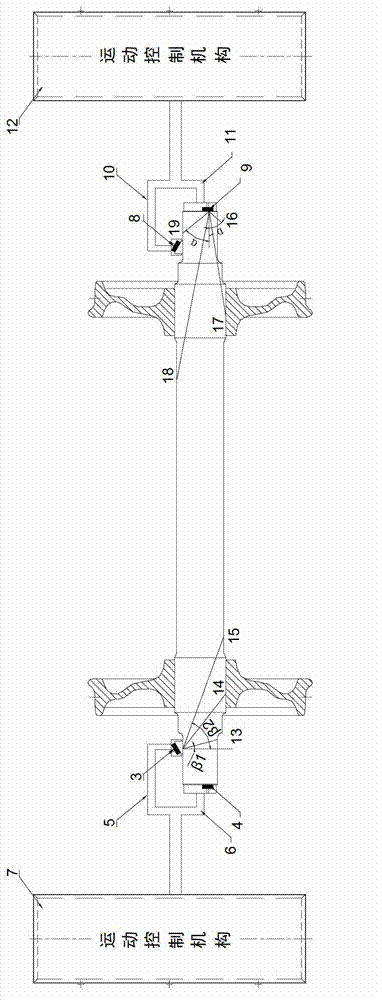

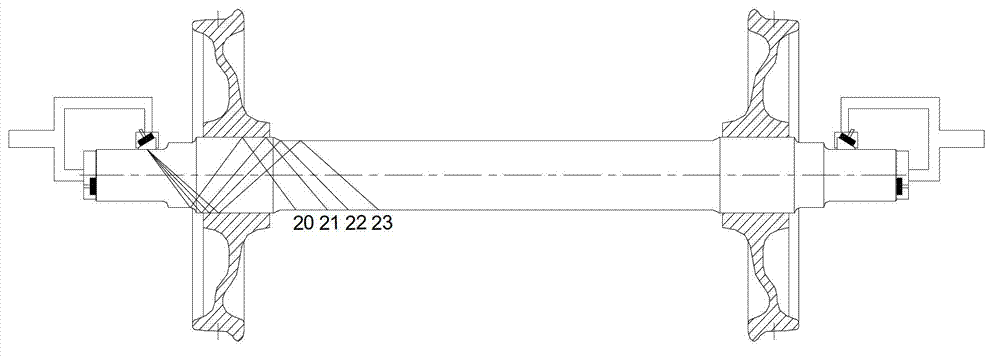

[0032] figure 1 , figure 2 , Figure 3a , Figure 3b , Figure 4 It is shown that a specific embodiment of the present invention is: a phased array ultrasonic detection device and method for a solid axle, using the deflection and focusing characteristics of the phased array ultrasonic to detect the axle journals 67, 68, wheel Seat 71,72, gear seat 73, holding journal 74,75, shaft body 76 positions are scanned. The top running wheel device 2 drives the wheel pair to perform circumferential motion 1 . When using this equipment for axle inspection, the ultrasonic coupling agent is oil, and under the condition that the surface of the axle shaft end and the journal surface of the axle are kept wet, the full coverage scan of all areas of the entire axle can be completed by rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com