Method for overcoming exposure region defect caused by underexposure

A technology of exposure area and underexposure, which is applied in the field of solving exposure area defects caused by underexposure, can solve problems such as exposure area defects, and achieve the effects of solving exposure area defects, eliminating photoresist residues, and saving process cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

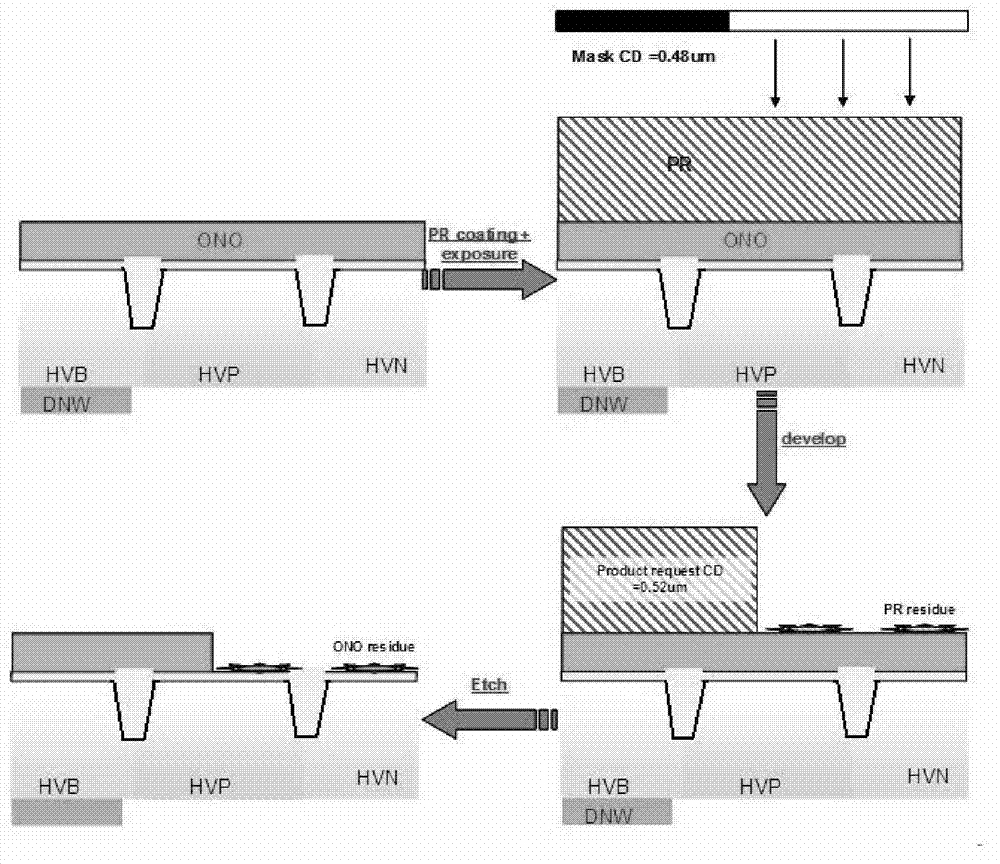

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

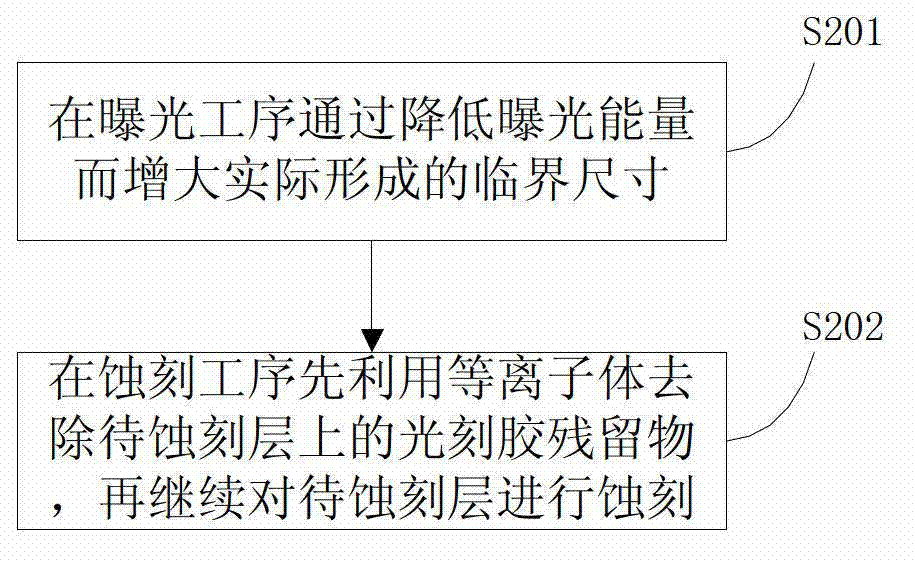

[0024] figure 2 It is a flow chart of a method for solving exposure area defects caused by underexposure provided by an embodiment of the present invention, and the method includes:

[0025] S201, increasing the actually formed critical dimension by reducing the exposure energy in the exposure process.

[0026] In the case of a given mask, when the critical dimension of the mask is smaller than the critical dimension required for actual production, the actual critical dimension of the product will be increased by reducing the exposure energy.

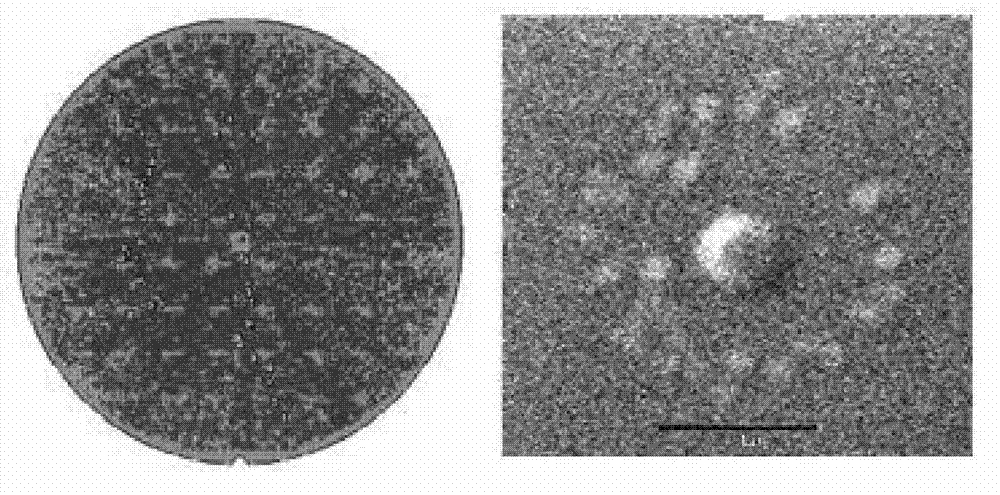

[0027] When the exposure energy is adjusted too much, it often leads to underexposure, which will cause photoresist residues to remain after development, reducing the accuracy of the subsequent etching process.

[0028] S202. In the etching process, firstl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com