Parallel genetic algorithm steam pipe system model auto-calibration system based on TBB (threading building block)

A technology of automatic calibration and genetic algorithm, applied in the field of steam pipe network model calibration calculation, can solve the problems that it is difficult to ensure a good estimate of the pressure drop coefficient of the pipe network, it is impossible to perform online measurement, and the calculation error is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

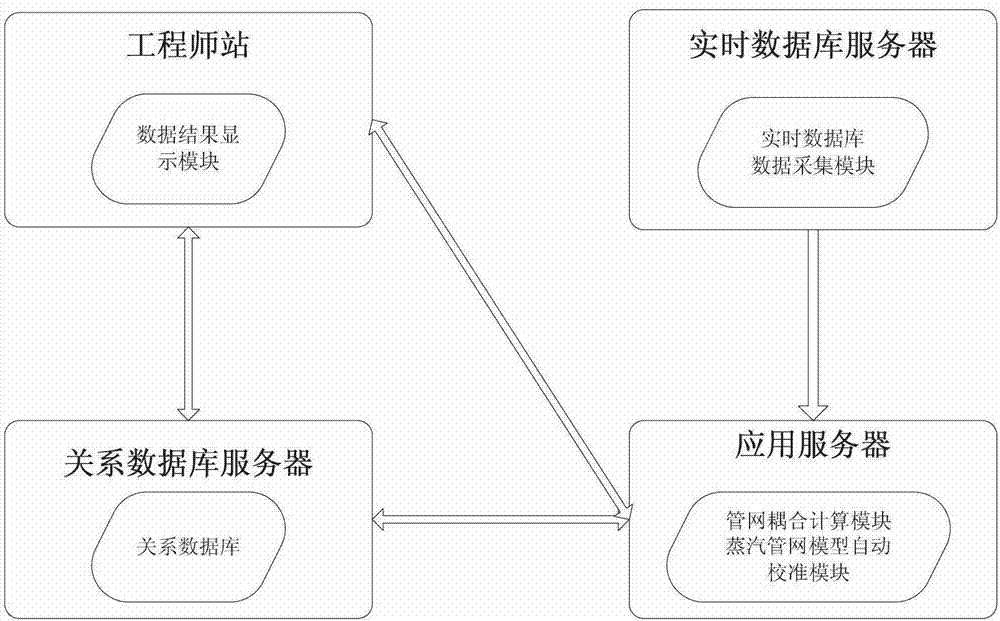

[0038] figure 1 It is a relationship diagram among the modules of the invention system. The system of the invention includes a relational database, a data acquisition module, a data result display module, a coupling calculation module and a pipe network automatic calibration module. The data result display module is deployed on the engineer station, the pipe network coupling calculation module and the automatic calibration module are deployed on the application server, the relational database is deployed on the relational database server, and the data acquisition module is deployed on the real-time database. The relational database is the data communication medium between the display module and the coupling calculation module and the friction coefficient identification module. The coupling calculation model and the friction identification program write the calculation results into the relational database, and the display module reads them out from the relational database and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com