Automatic feeding and discharging mechanism of jig

A technology for feeding and unloading materials and fixtures, which is applied in the direction of conveyors, coil manufacturing, electrical components, etc., can solve problems such as difficulty in widespread use, waste of raw materials, and low efficiency, so as to reduce the use of manpower, ensure material supply, and improve coordination. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

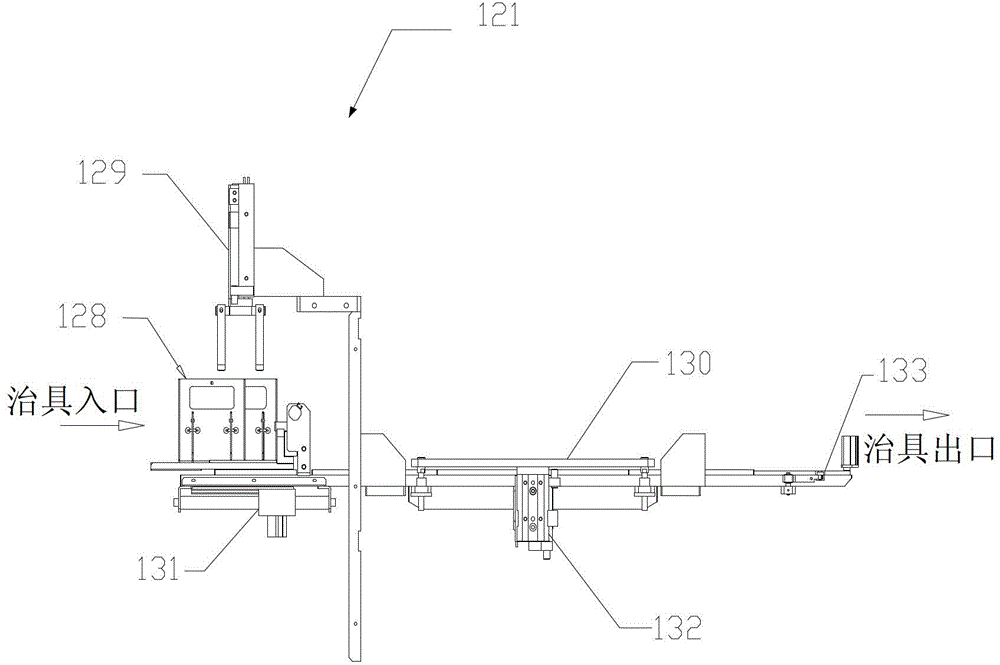

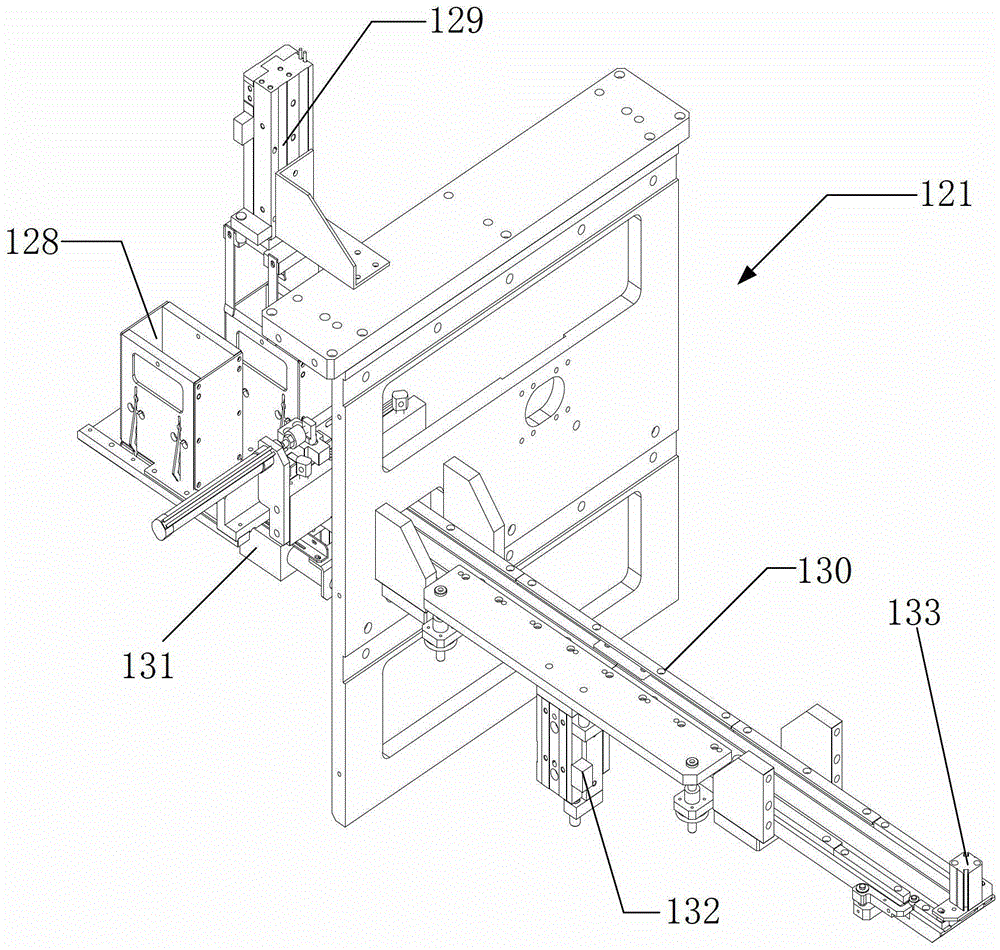

[0019] Please refer to figure 1 and figure 2 , figure 1 Shown is a schematic structural view of the jig automatic feeding and discharging mechanism in a preferred embodiment of the present invention, figure 2 Shown is a three-dimensional schematic view of the jig automatic feeding and discharging mechanism in a preferred embodiment of the present invention. The present invention proposes an automatic feeding and discharging mechanism for jigs, including: a feeding jig mechanism 121; a jig silo 128, which is arranged on the feeding jig mechanism 121 for feeding jigs; a feeding bin feeding cylinder 129 , set on the feeding jig mechanism 121 and above the jig bin 128; the bin advance cylinder 131, connected to the jig bin 128, is used to drive the jig to move; the discharge positioning mechanism 133 , connected to the feeding jig mechanism 121 , used to discharge the jig after the winding operation is completed.

[0020] According to a preferred embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com