Stator winding hot-immersion and heating system and process

A stator winding and heating system technology, applied in electric components, manufacturing motor generators, electrical components, etc., can solve the problems of easy loss of insulating varnish, large winding gap, long time, etc., to reduce the loss of insulating varnish and reduce dripping Time, solve the effect of poor permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

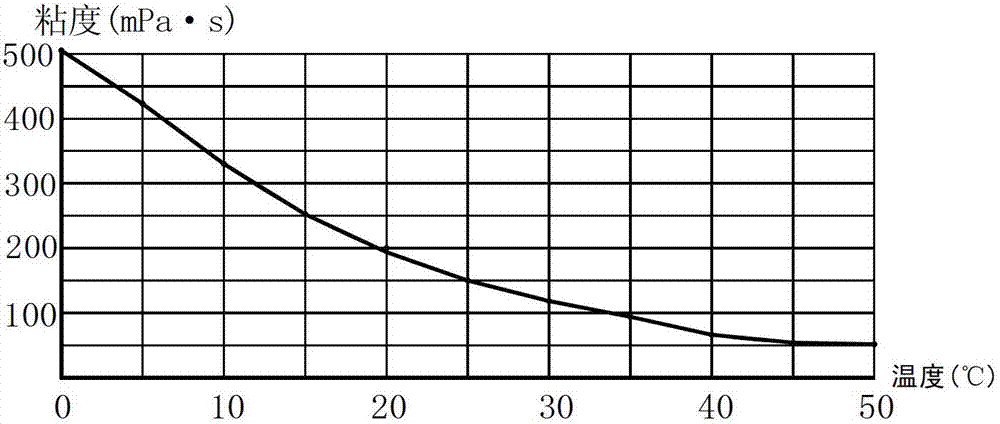

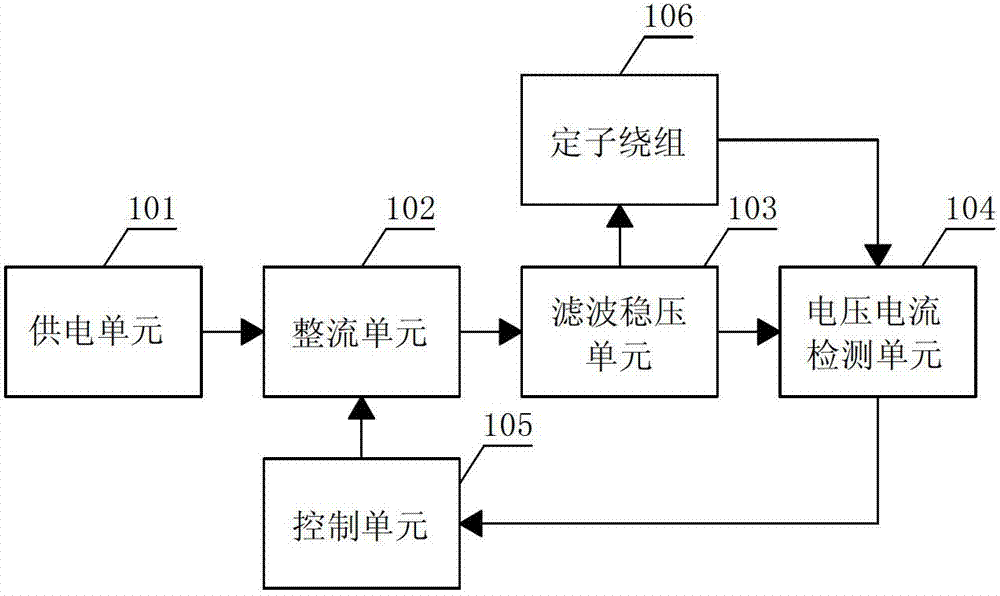

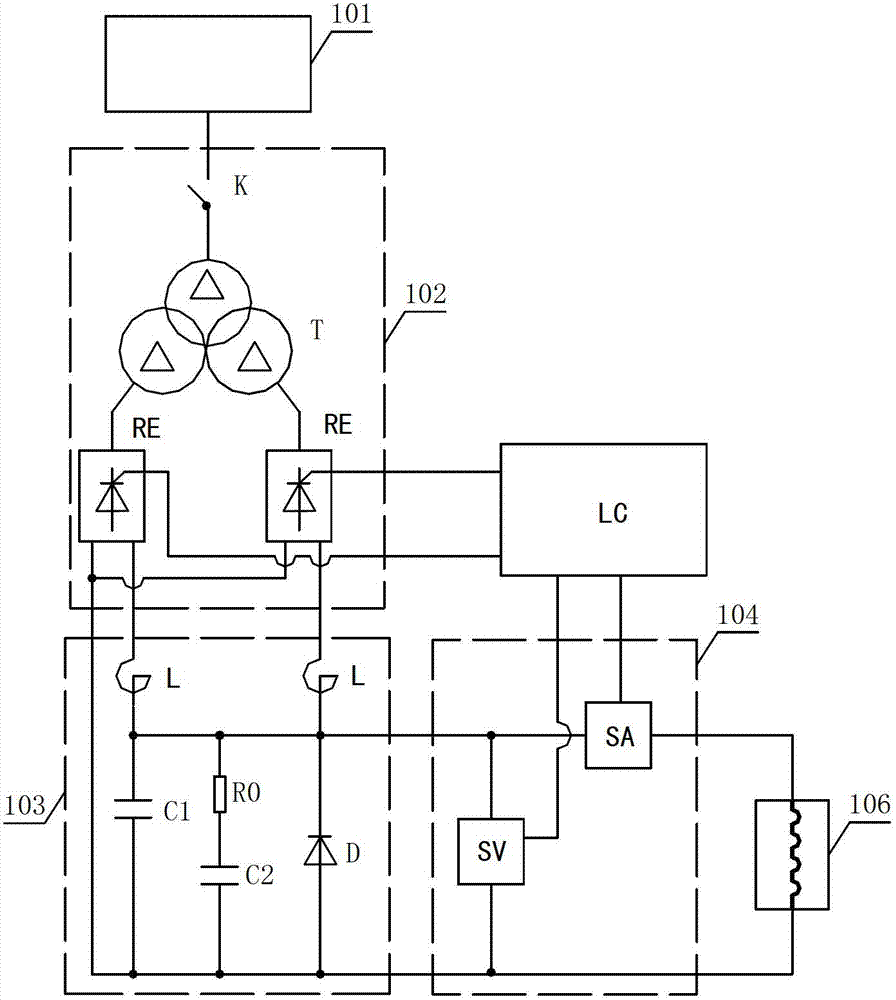

[0042] The principle of the invention is as follows: The first important property of insulating varnishes is the negative dependence of viscosity on temperature. Such as figure 1 as shown, figure 1Shown is a graph of viscosity versus temperature for a typical insulating varnish. It can be seen from the figure that with the increase of the temperature of the insulating varnish, the viscosity of the insulating varnish drops sharply. , the viscosity dropped to 54mPa·s. Therefore, we can take advantage of this feature, use high-viscosity insulating varnish, and heat the stator winding to an appropriate high temperature (such as 50-60°C) through the heating system when the stator winding is dipped in varnish, so that the insulating varnish in contact with the stator winding The local temperature rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com