Scraper knife

A shovel and planer technology, which is applied in the field of shovels, can solve the problems of high labor consumption, difficult storage, and hard work of workers, and achieve the effect of reasonable opening depth, easy storage, and even shaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

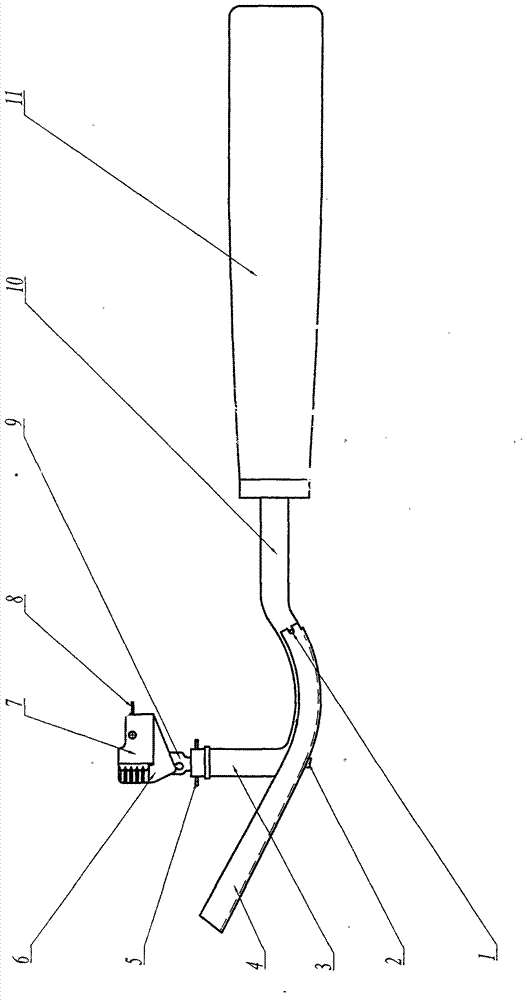

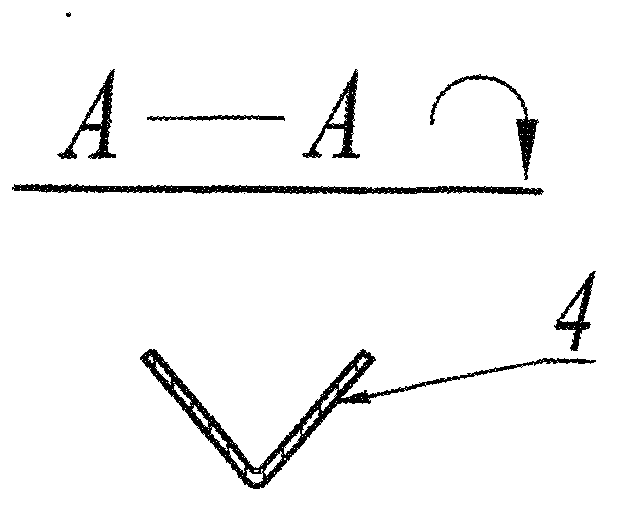

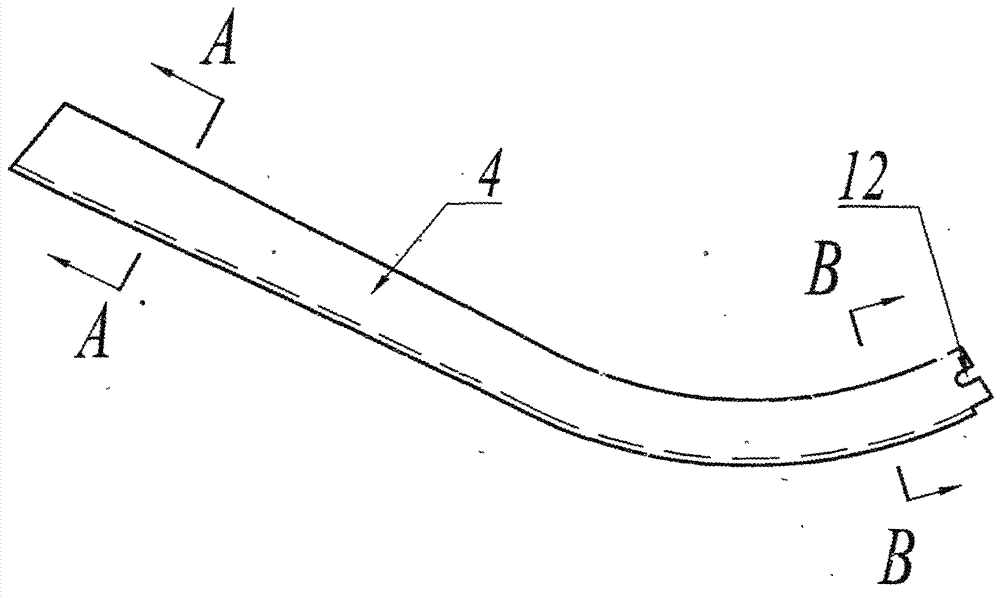

[0024] The preferred embodiment of the present invention is like this, with reference to Figure 1 to Figure 14 , the front end of the handle (11) is equipped with a handle hook bar (10), and the front section of the handle hook bar (10) bends up for a section to be a vertical hook bar (3), and the two sides of the handle hook bar (10) at the lower bending point are the first fulcrum Pin (1), the shovel body (4) tail end face symmetrically has tooth opening (12), and the tooth mouth (12) of shovel body (4) tail end snaps into the first fulcrum pin (1) and fixes. The shovel body (4) front section is V-shaped, and the rear section is a U-shaped inner cavity. The V-shaped is a working bar, and the U-shaped is a mounting bar. 3) The second fulcrum pin (2) with a cap is installed on the bottom end, and the second fulcrum pin (2) passes through the slotted hole (13) under the blade body (4), and the aperture of the slotted hole (13) is smaller than that of the second fulcrum Pin (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com