Two-way rotating grinding head provided with planetary grinding discs and specially used for retreading machine

A bidirectional rotation and refurbishment machine technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of difficult and laborious operation, high cost and maintenance probability, and large reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

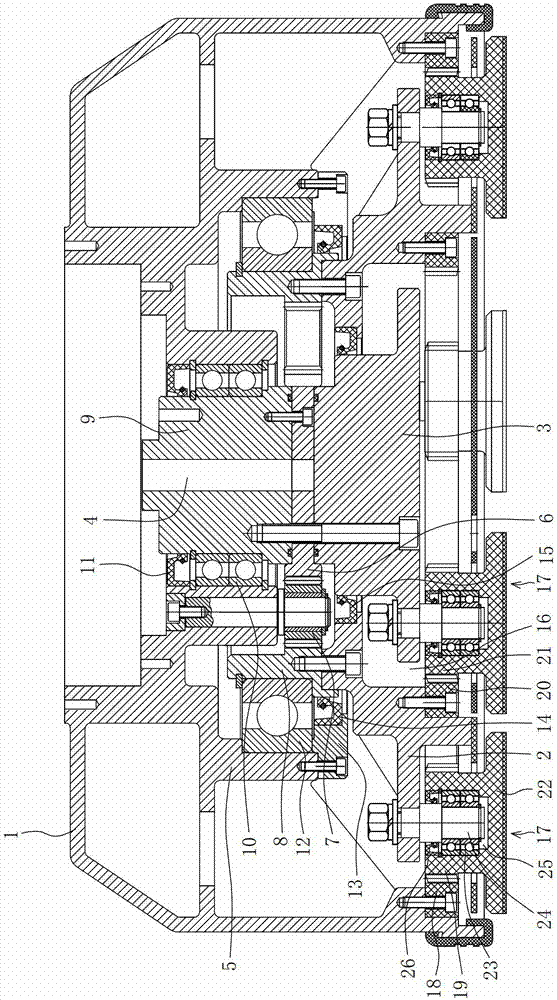

[0011] Now elaborate this technical scheme in conjunction with accompanying drawing:

[0012] The special two-way rotary grinding head for refurbishing machines with planetary grinding discs in this embodiment includes a fixed disc 1, an outer rotating disc 2, an inner rotating disc 3 and a central axis 4 connected to the power unit, and the inner rotating disc 3 is installed on the central axis 4 On the top, there is a mounting ring 5 extending downward from the top of the fixed disk 1, and a transmission device is connected between the central shaft 4 and the outer rotating disk 2. The transmission device is a planetary gear train, and the planetary gear train is composed of the first sun gear 6 1. The first planetary gear 7 and the first inner ring gear 8 are formed. On the central shaft 4 and above the inner rotating disk 3, a central shaft wheel 9 is fixedly set. The power unit drives the central shaft wheel 9 to rotate, and the central shaft wheel 9 Drive the central sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com