Stamping part clamp

A technology for stamping fixtures and plastic clamps, applied in the field of stamping fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

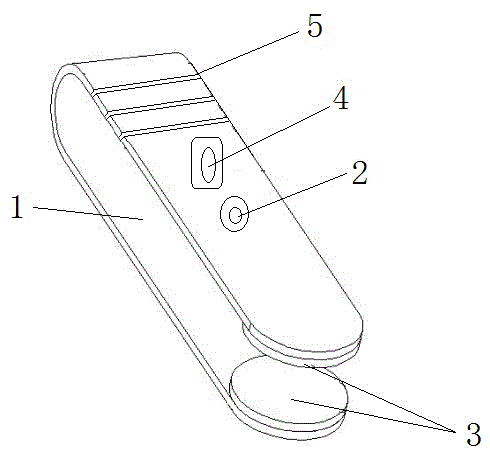

[0014] Such as figure 1 As shown, a clamp for stamping parts includes a U-shaped plastic clamp body 1. The surface of the rear end of the plastic clamp body 1 is also provided with an anti-slip groove 5, which is convenient to hold and has an anti-slip function. The plastic clamp body 1 There is a button battery 4 inside, which is used to pass the operating voltage to the electromagnet 3. The electromagnet 3 is installed on the inside of the front end of the plastic clip body 1 close to the opening, because the cylindrical electromagnet 3 is very common, easy to obtain, and cheap. The shape of electromagnet 3 is selected as cylindrical, beautiful in appearance, and the outer surface of plastic clip body 1 is provided with power switch 2, and button cell 4 is connected with the lead-out end of electromagnet 3 through power switch 2, when taking stamping parts, Press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com