Intelligent loading and unloading machine system

A loading and unloading machine, intelligent technology, applied in the field of mechanical equipment control, can solve the problems of inconvenient lateral movement, high labor cost, low work efficiency, etc., achieve the effect of convenient loading and unloading process, flexible and convenient lines, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

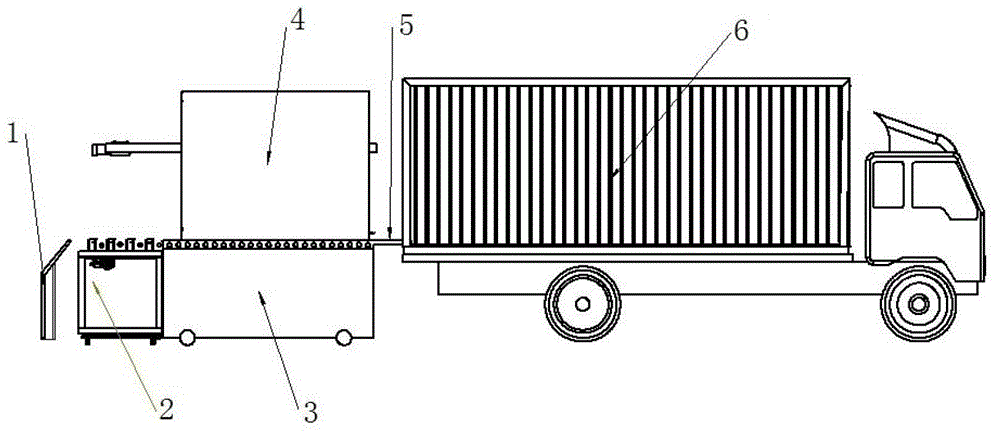

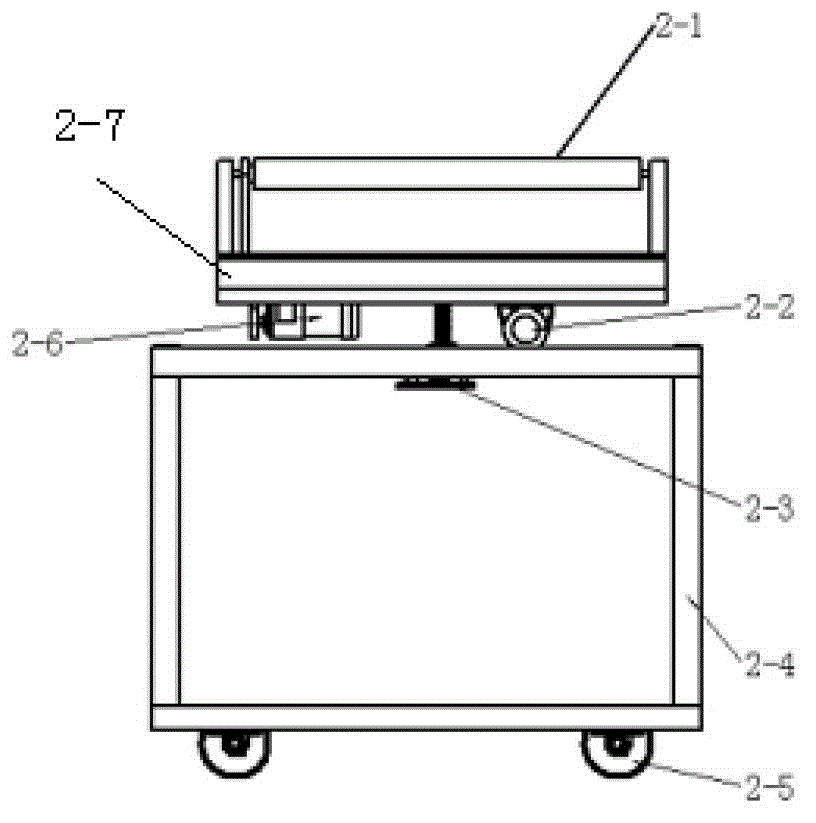

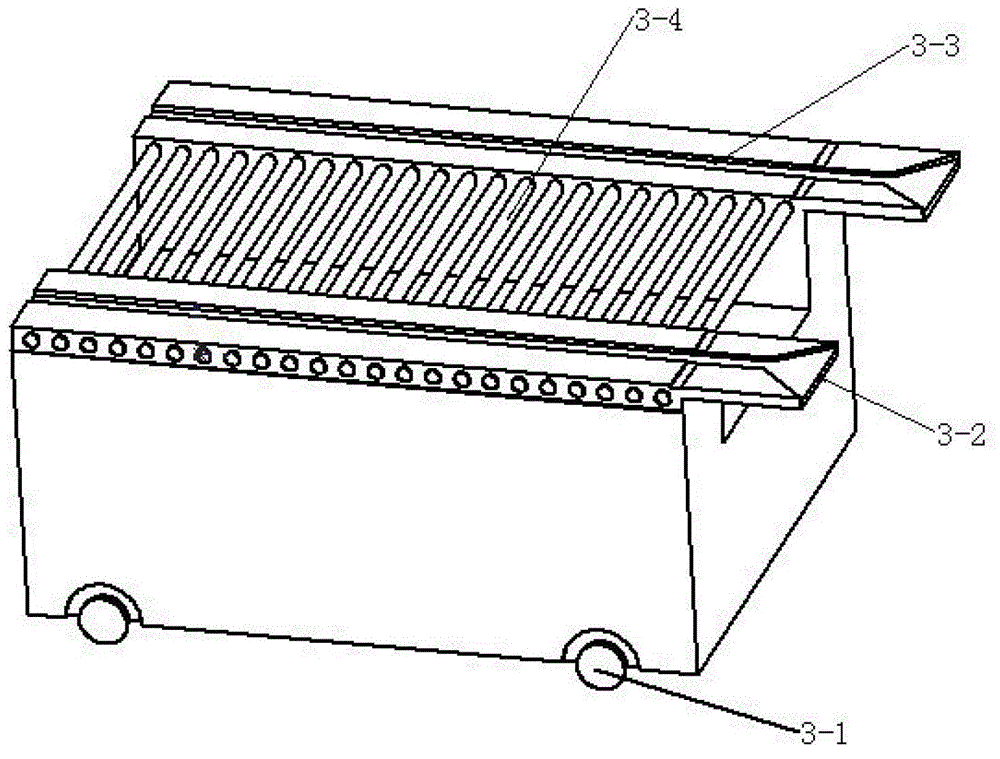

[0021] Such as figure 1 As shown, an intelligent loading and unloading machine system includes a field operation console 1, a cargo steering platform 2, a loading and unloading machine host 3, an intelligent loading and unloading operation locomotive 4, a connecting plate 5, and a truck 6; The position of the loading and unloading machine host 3 is connected to the right side of the cargo steering platform 2, the intelligent loading and unloading operation head 4 is slidingly connected to the upper surface of the loading and unloading machine host 3, and the connecting plate 5 is arranged at the right end of the loading and unloading machine host 3. When unloading, the connecting plate 5 can automatically Put it down and connect with the 6 compartments of the truck; the on-site operation console 1 is provided with a PLC touch screen, and the PLC liquid crystal touch screen ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap