Steam heat pipe drying method and system for sewage sludge

A sewage sludge and heat pipe technology, applied in dehydration/drying/concentrated sludge treatment, chemical instruments and methods, separation of dispersed particles, etc., to achieve the effects of continuous operation, odor removal, and simplified treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

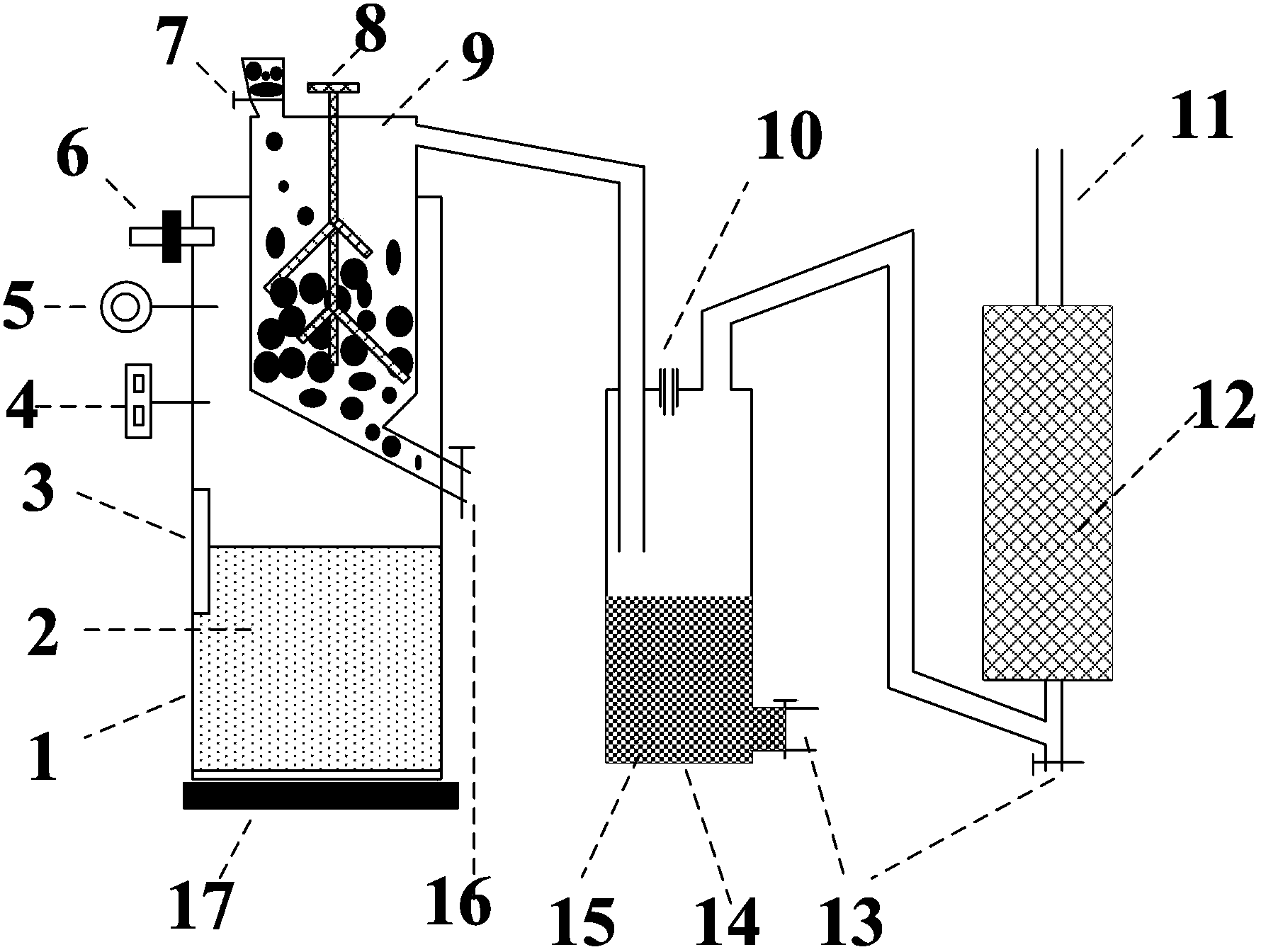

[0023] see figure 1 Shown, a kind of sewage sludge steam heat pipe type drying method comprises the following steps:

[0024] Step 1: Use waste heat flue gas and other low-grade external heat sources 17 to heat the closed barrel steam generator 1 to generate steam, and the deionized water 2 is heated to generate steam and move upward. The heating temperature is 150-200°C and the air pressure is 0.48-1.55Mpa ;

[0025] Step 2: The steam generated by heating rises and contacts the wall of the drier 9 to dry the sludge in the drier 9;

[0026] Step 3: After being cooled, the steam descends back to the bottom of the steam generator 1 and is reheated. This process forms a heat pipe-type working fluid internal circulation.

[0027] The sludge in the above step 2 enters the dryer 9 from the sludge bin 7, and is stirred and mixed by a plow-shaped agitator 18 to realize sludge mixing and moving down to enhance uniform drying; the dried sludge is discharged through the outlet 16 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com