Method for preparing conotoxin polypeptide Eb1.6

A technology of eb1.6 and Cono snails, applied in the biological field, can solve the problems of unfavorable manual mass synthesis, inconvenience of condensation reaction and resin washing, and high cost, and achieves correct disulfide bond pairing method, high recovery rate, and realizes repeated recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the large-scale preparation of cone snail polypeptide Eb1.6

[0034] 1. Exploration of the conditions for large-scale preparation of the cone snail polypeptide Eb1.6

[0035] 1. The effect of different condensing agents on the manual solid-phase synthesis efficiency of Eb1.6 linear peptide

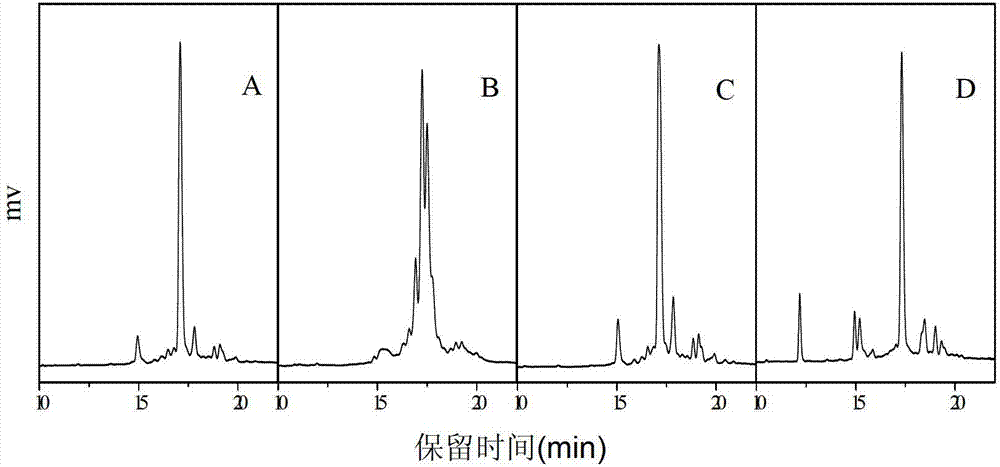

[0036] The pre-synthesis of Eb1.6 linear peptide was synthesized by an instrument, carried out on a 433A peptide synthesizer (ABI Applied Systems Biological Instruments), using Fmoc-protected amino acids (Shanghai Jill Biochemical Co., Ltd.) and a substitution rate of 0.60mmol / g Rink resin, condensing agent is DCC / HOBt. In the reaction system, the molar ratio of resin to amino acid is 1:5, 0.1mmol peptide resin is synthesized each time, and the coupling rate is high ( figure 1 -A). However, this method is not conducive to large-scale manual synthesis, because the condensing agent DCC reacts to form N,N'-dicyclohexylurea (DCU) which is insoluble in N,N-dimethylformam...

Embodiment 2

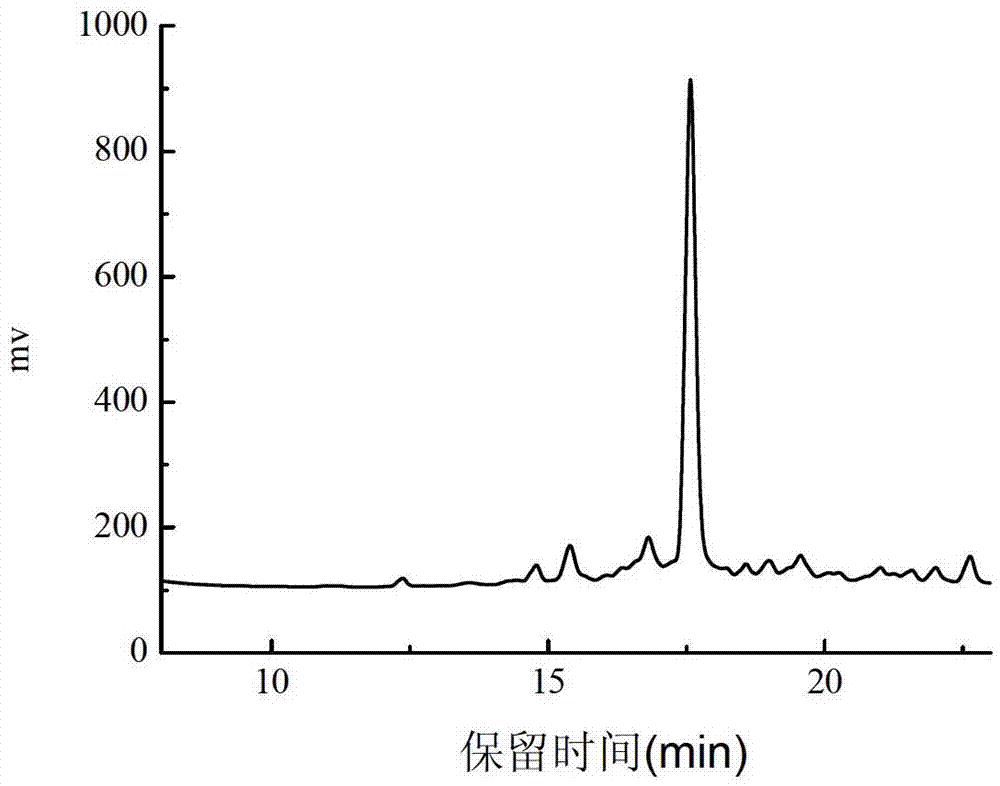

[0066] Embodiment 2, the detection of polypeptide Eb1.6

[0067]The above-mentioned purified polypeptide Eb1.6 obtained in Example 1 was sequenced, and its amino acid sequence was sequence 1 in the sequence table, and then the polypeptide was further detected as follows:

[0068] 1. Determination of polypeptide Eb1.6 disulfide bond

[0069] The determination of the disulfide bond of polypeptide Eb1.6 adopts a two-step folding method:

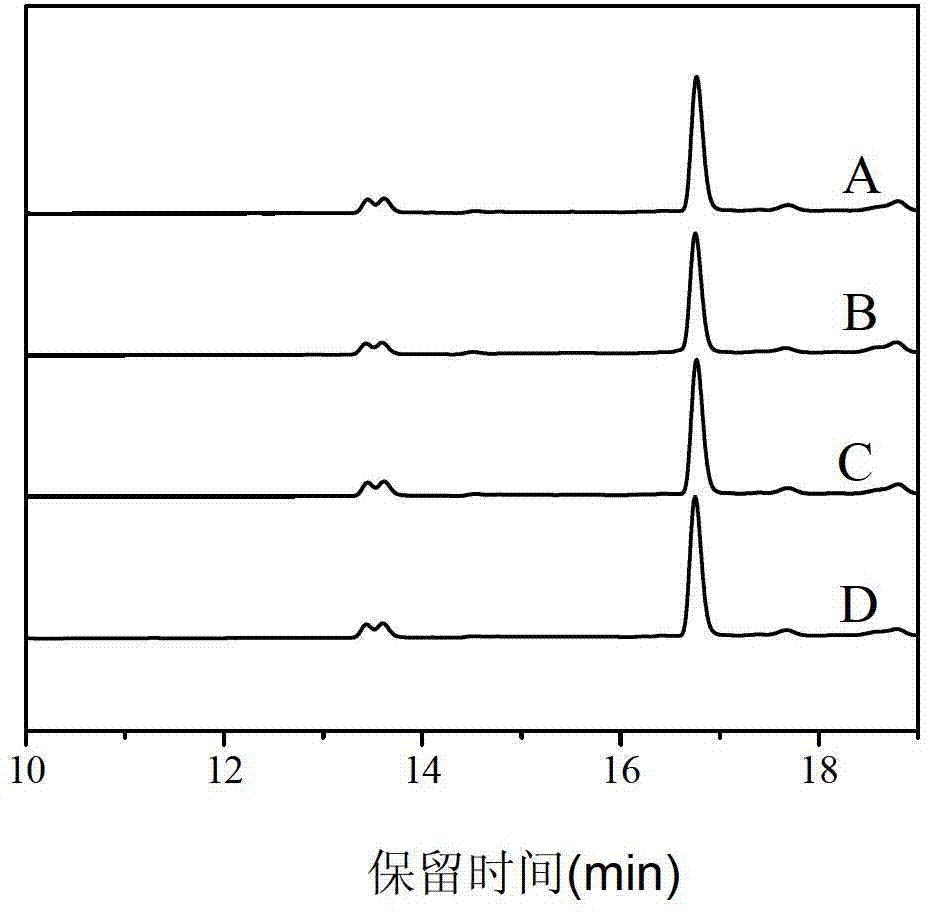

[0070] First, the linear peptide Eb1.6 was synthesized (synthetic method is the same as step 1 of Experiment 2 in Example 1 above). The first step was air oxidation folding to form the first pair of disulfide bonds (Cys1-Cys3), and then the iodine was oxidized to remove the Acm protecting group to form the first pair of disulfide bonds. Two pairs of disulfide bonds (Cys1-Cys3, Cys2-Cys4), the first step of oxidative folding conditions: 0.1M Tris-HCl buffer, pH = 7.7, magnetic stirring for about 28h, HPLC analysis of the folding process. The fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Replacement rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com