Method for determining position of erosion line of hearth of blast furnace

A determination method and blast furnace technology, applied in the field of blast furnace longevity, can solve the problems of unreasonable demarcation point, reduced calculation amount, and large amount of calculation, and achieve the improvement of calculation stability, reduction of calculation amount, and short calculation period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

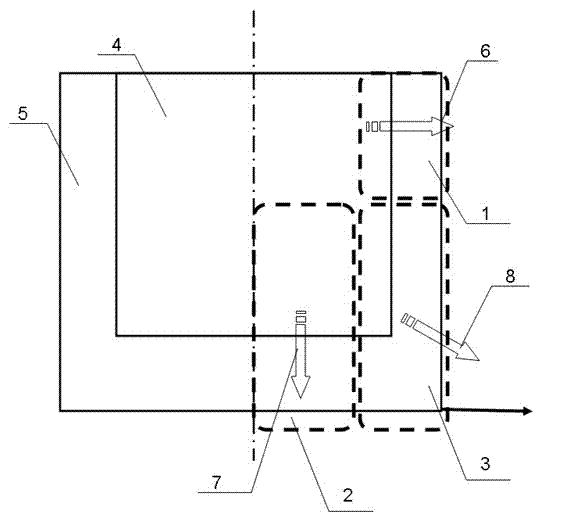

Image

Examples

Embodiment Construction

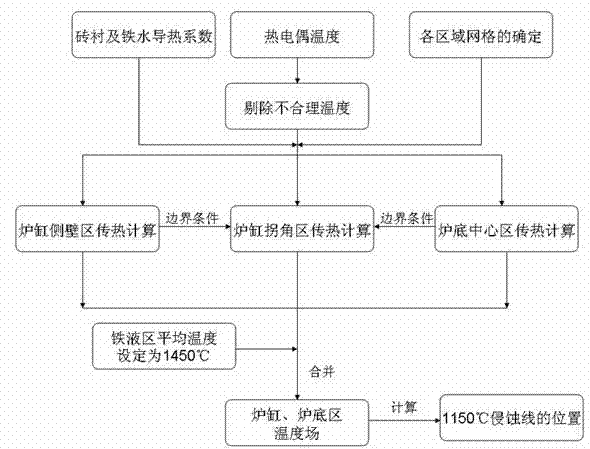

[0016] In order to overcome the deficiencies of the prior art in blast furnace longevity monitoring, in a nutshell: the present invention calculates the temperature field in the hearth brick lining directly with the finite element or finite difference method of the stable grid based on the steady-state heat conduction equation, and iteratively In the calculation, the thermal conductivity of the brick lining is determined according to the temperature of the grid nodes. If the temperature is higher than 1450 ° C, the effective thermal conductivity of molten iron will be used to calculate and determine the temperature field in the hearth brick lining, and the position of the erosion line at 1150 ° C is determined according to the temperature field , this method of determining the position of the erosion line only needs to calculate the temperature field once, so compared with the previous method, the calculation amount is greatly reduced, the calculation period is short, and it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com