Steel net rack installation method for integrally improving high-altitude moving and positioning

An overall lifting and installation method technology, which is applied in the direction of construction and building construction, can solve the problems of large overturning moment of the hoist pulley block system, the large change in the overturning moment of the pulling rod group, the complex force of the hoist pulley block, and the small area of the overall stiffness. High-altitude operation, convenient construction and simple lifting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

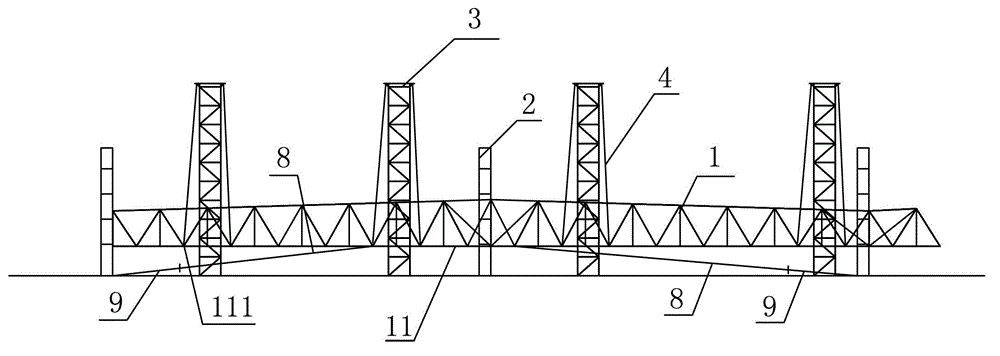

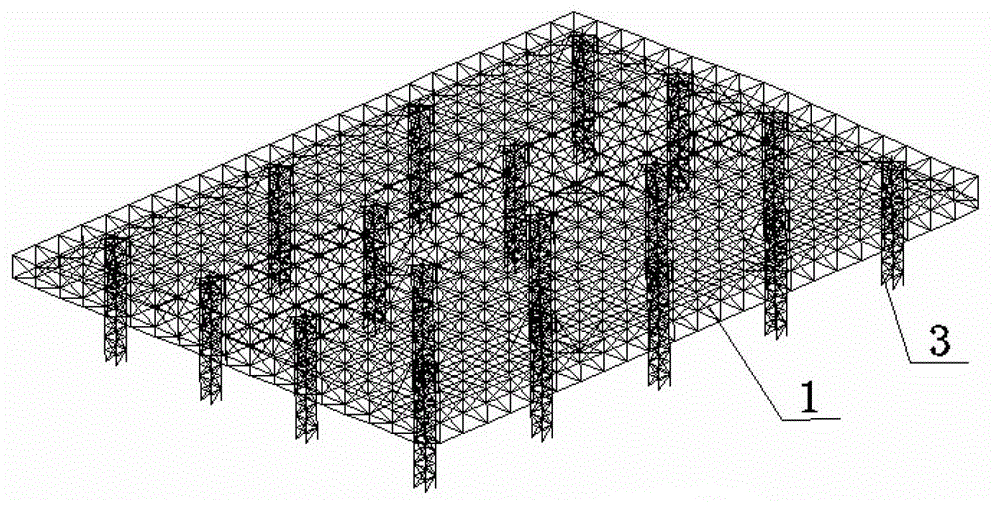

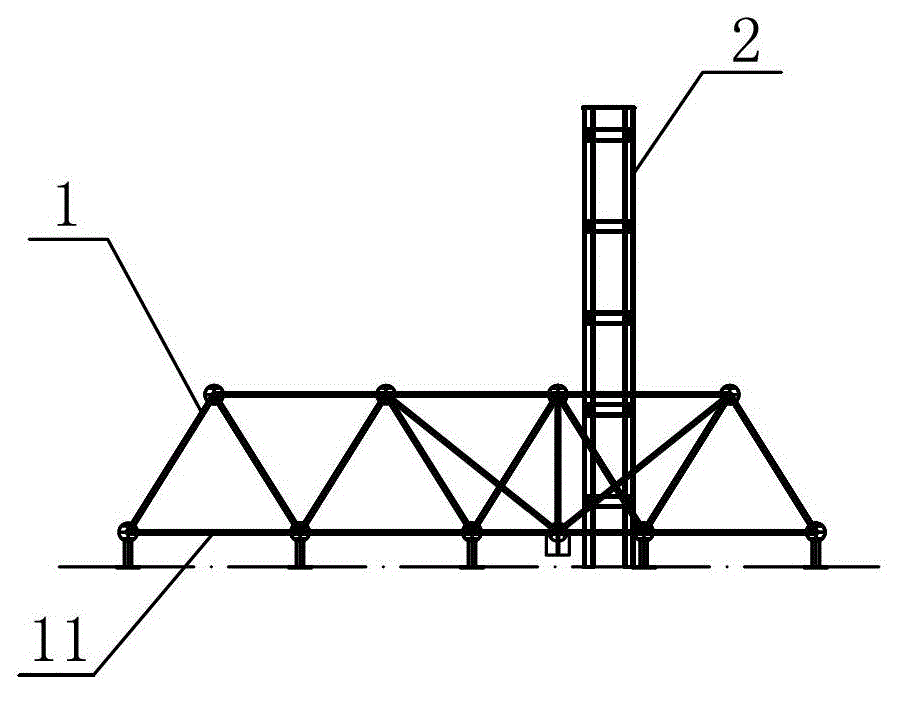

[0045] Such as figure 1 , 2 As shown, the present invention adopts a multi-fulcrum system, and uses an inverted chain as a lifting device to lift the assembled network frame 1 on the ground to the required height and move at high altitude by redistributing the force of the lifted inverted chain 4, and finally locates on the grid. The rack supports the top of the structural column 2.

[0046] An installation method of a steel grid frame for overall lifting and moving in place at a high altitude, which is carried out according to the following steps:

[0047] 1) if Figure 3a , 3b , 4a, 4b, according to the design conditions, determine the initial offset between the ground assembly position of the grid 1 and the support structure column 2 of the grid in the diagonal direction of the orthogonal grid, and the initial offset is generally be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com