Static and dynamic combined intelligent pre-warning anchor rod

An intelligent, dynamic and static technology, applied in the installation of bolts, mining devices, mining equipment, etc., can solve the problems of interference and influence of monitoring results, inability to realize non-destructive real-time monitoring and early warning of surrounding rock and rock burst, and achieve the effect of reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

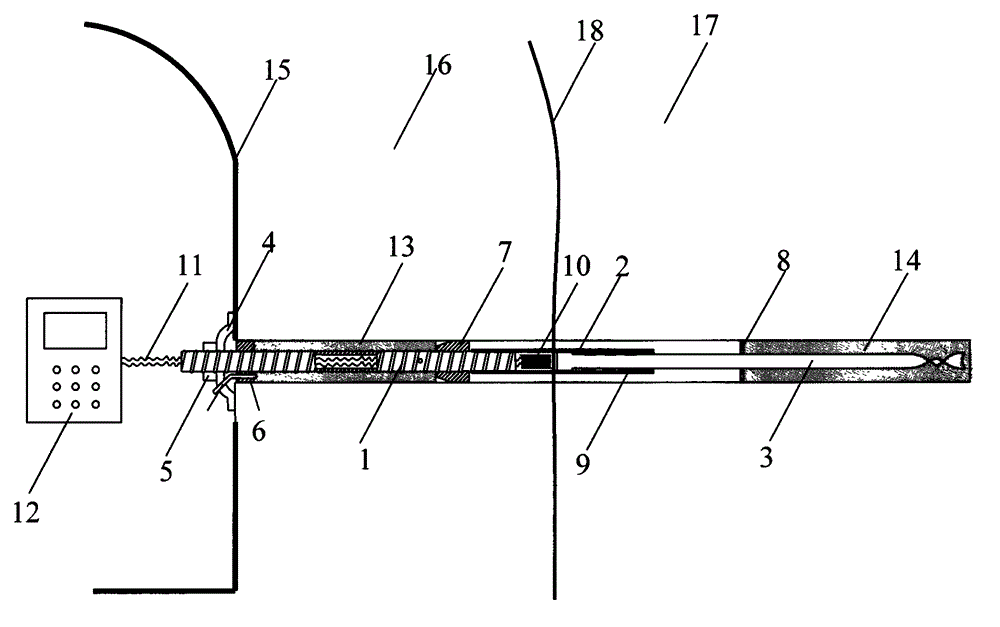

[0019] Embodiment 1: Referring to shown in Fig. 1, the hard and brittle surrounding rock cavern will form a fracture softening zone 16 and an elastic zone 17 under the action of high ground stress, and the boundary 18 of the crack softening zone can be measured by acoustic wave testing equipment; According to the anchorage design specification, high-strength rebar is selected to process the hollow grouting rod body 1 and the solid rod body 3 respectively. The hollow grouting rod body 1 is provided with a grout hole, and its surface thread should facilitate the installation of the casing 2, the nut 5, the inner grout stopper 6 and the outer grout stopper 7, and the tray 4 and the outer grout stopper 6 are provided with exhaust holes. aisle. One end of the solid rod body 3 is a stirring wing, and the other end is socketed with a sleeve. The rod body at the sleeve end is provided with a cylindrical blocking block with a slightly larger diameter and a certain number of three sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com