Drive gear assembly capable of locating by fine adjustment

A technology for transmission gears and driven gears, which is applied to transmission parts, belts/chains/gears, rigid shaft couplings, etc., and can solve the problems of low machining efficiency of precision positioning holes, difficulty in machining precision positioning holes, and inaccurate transmission positioning. Accuracy and other issues, to achieve the effect of simple structure, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

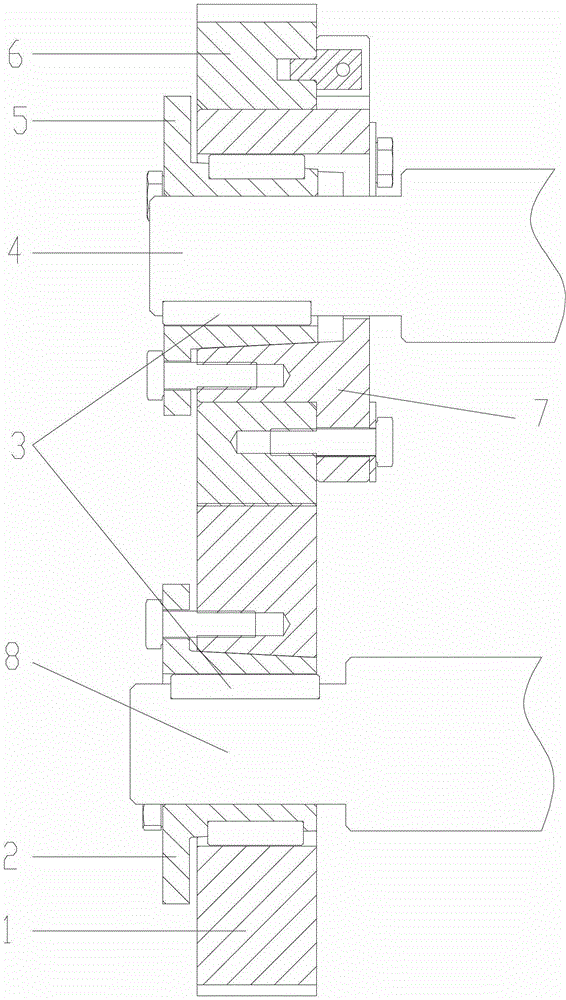

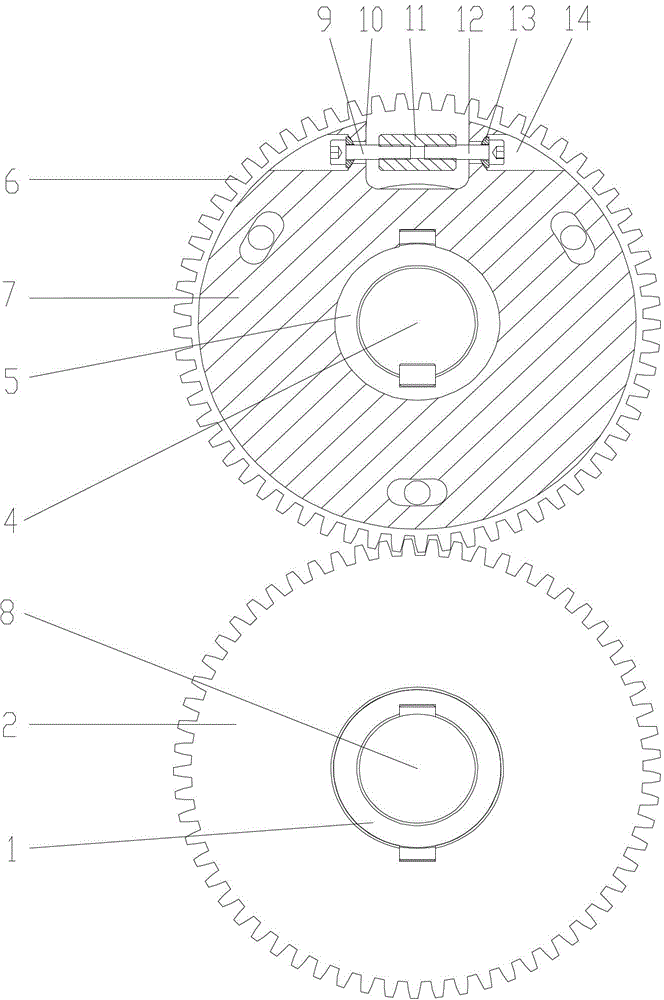

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the left view of the present invention, as shown in the figure, a finely adjustable and positioned transmission gear assembly provided by the present invention includes a driving gear 1, a driving shaft 8 coaxially fixedly fitted with the driving gear 1, and a driven gear 6 and the driven shaft 4 coaxially fixedly fitted with the driven gear 6, the driving gear 1 meshes with the driven gear 6, and the driven gear 6 is provided with a The adjustment device for the relative position of the working parts on it;

[0021] The adjustment device includes an outer coupling sleeve 7, an adjustment column 11 for adjusting the outer coupling sleeve 7, and a driven inner expansion sleeve 5. The driven inner expansion sleeve 5 is sleeved on the driven shaft 4, and is passed through a flat key 3 for fastening, the outer coupling sleeve 7 is overlaid on the driven inner expansion sleeve 5, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com