Metal purification furnace

A metal and furnace body technology, applied in the field of metal processing and purification devices, can solve the problems of poor sealing effect of the furnace body, poor temperature regulation and control ability, large energy loss, etc., and achieve the effect of simple structure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

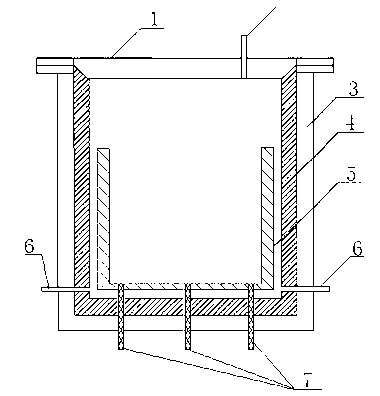

[0009] as attached figure 1 Shown is a metal purification furnace, including a furnace body with a cylindrical inner cavity, an upper cover 1 and a heater 5, the upper cover 1 covers the upper end of the furnace body, and is locked by a flange structure, and the upper cover 1 There is an air extraction hole 2 on the top, and a temperature-regulating layer 3 and an insulating layer 4 are sequentially arranged on the inner cavity wall of the furnace body. The heater 5 powered by the three-phase electrode 7 is arranged inside the insulating layer, and its outer wall and the insulating layer 4 The distances on the inner wall are equal and not equal to zero; the air delivery hole 6 is arranged at the bottom of the cylindrical side of the furnace body, connecting the inside and outside of the heating chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com