Measuring method for friction distribution of inner wall of confining device

A measurement method and technology in the device, which are applied in the direction of measurement force, measurement device, instrument, etc., to achieve the effect of simple instrument and equipment, simple data acquisition and processing method, and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] A method for measuring the distribution of friction force on the inner wall of a confining pressure device, characterized in that it includes the following specific steps:

[0021] 1) Take two symmetrical parts on the outer surface of the confining pressure device, first use coarse emery cloth, then use fine emery cloth, and grind out a smooth band-shaped area with a width of 1cm to 2cm along the axial direction;

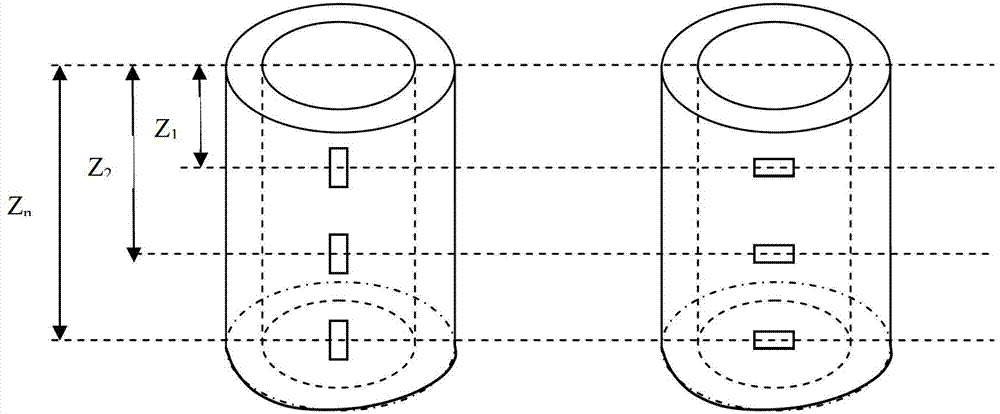

[0022] 2) Determine the number of required strain gauges according to the axial length of the confining pressure device, and stick the axial strain gauges in sequence along the axial direction in one of the smooth strip-shaped areas, with a certain distance between two adjacent strain gauges and record the distance from the center of each resistance strain gauge to the top of the confining pressure device, which are recorded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com