Gravel soil mechanical property evaluation method

An evaluation method and technology of soil mechanics, applied in soil material testing, material inspection products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific implementation mode 1: see 1-2, the specific process of a method for evaluating the mechanical properties of gravel soil described in this implementation mode is:

[0033] Step A, correction process of super heavy dynamic penetrating hammer number:

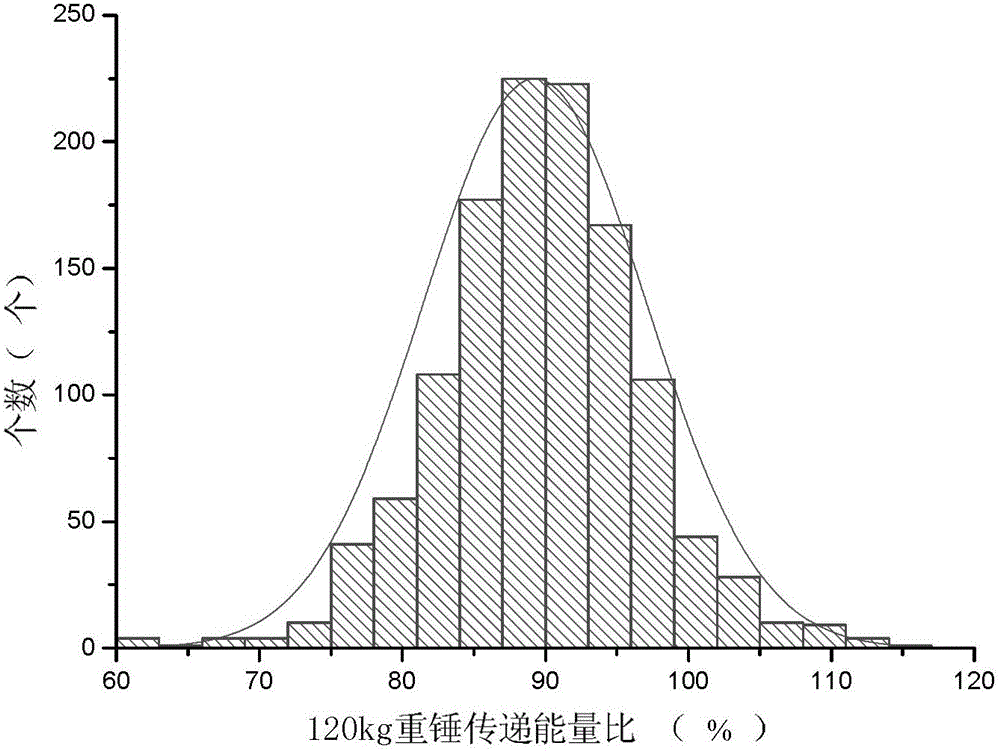

[0034] Step A1. Select a typical gravel soil site, use super heavy dynamic penetrating sounding standard probe and 120kg standard weight to conduct super heavy dynamic penetrating sounding test, test the energy transmitted by the heavy hammer to the drill pipe, and calculate the ratio of the transmitted energy to the theoretical total energy , a total of more than 1200 basic data were obtained;

[0035] Step A2. According to statistics of more than 1200 data, the energy ratio delivered by the 120kg heavy hammer of the ultra-heavy-duty dynamic penetrating test under the conventional operating procedures has an average value of about 90% and a standard deviation of 7.8%;

[0036] Step A3, using super-heavy power pen...

Embodiment

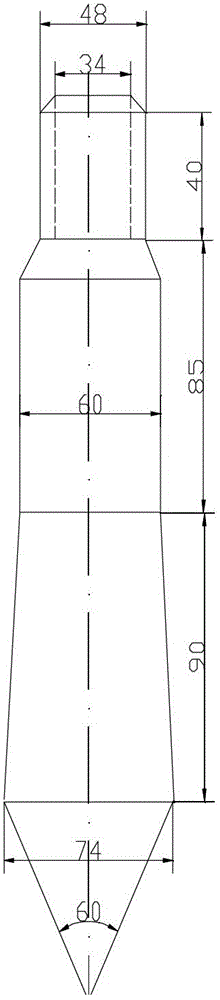

[0055] 1. Adopt super heavy-duty dynamic penetrating probe standard probe ( figure 2 );

[0056] 2. If the ultra-heavy-duty dynamic penetration penetrating 120kg heavy hammer is used, the hammer number obtained from the test will not be corrected for energy;

[0057] 3. If other hammers with different hammering energy are used, it is necessary to measure the transfer energy of the hammer used, and calculate the transfer energy ratio according to the theoretical total energy of the 120kg hammer, which is 1.2kN.m, and perform energy correction according to formula (6) ;

[0058] 4. The number of power penetrating strikes after energy correction N m-120 (stroke / 30cm), the degree of compaction of gravel soil is determined according to Table 1:

[0059] Table 1 Classification of compactness of gravel soil

[0060]

[0061] 5. Using the number of power penetrating strikes after energy correction N m-120 , to judge the liquefaction of gravel soil:

[0062] 1) Calculate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com