Scott transformer

A technology of transformers and single-phase transformers, applied in the field of transformers, can solve the problems that transformers cannot meet industrial applications, do not have the function of three-phase to two-phase vector transformation, and the power supply device is too large, and achieve simple structure, small footprint, Use cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

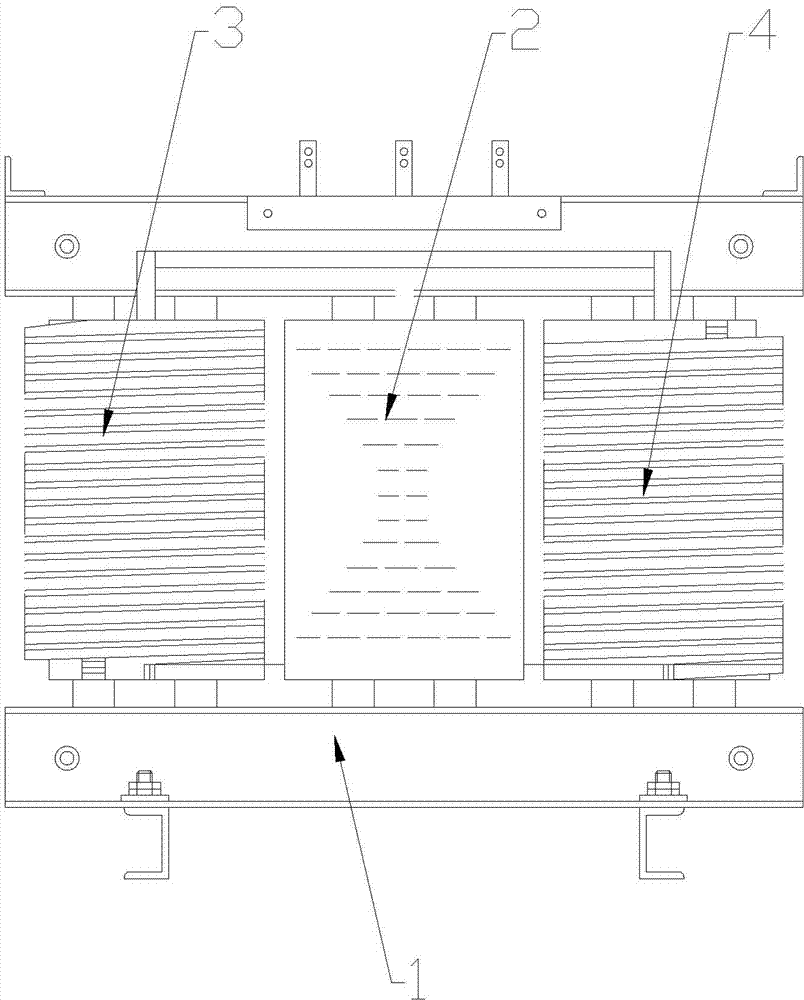

[0013] Such as figure 1 Shown: a Scott transformer, including a transformer mounting frame 1 made of channel steel, in the middle of the transformer mounting frame 1 is provided with an iron core 2 fixedly installed in the transformer mounting frame 1, on both sides of the iron core 2 A first transformer 3 and a second transformer 4 located in the transformer installation frame 1 are respectively provided. The first transformer 3 and the second transformer 4 are all single-phase transformers, wherein the high-voltage winding end of the first transformer 3 is connected to the end of the second transformer 4. The center point of the high voltage winding is connected or the end of the high voltage winding of the second transformer 4 is connected with the center point of the high voltage winding of the first transformer 3 .

[0014] In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com