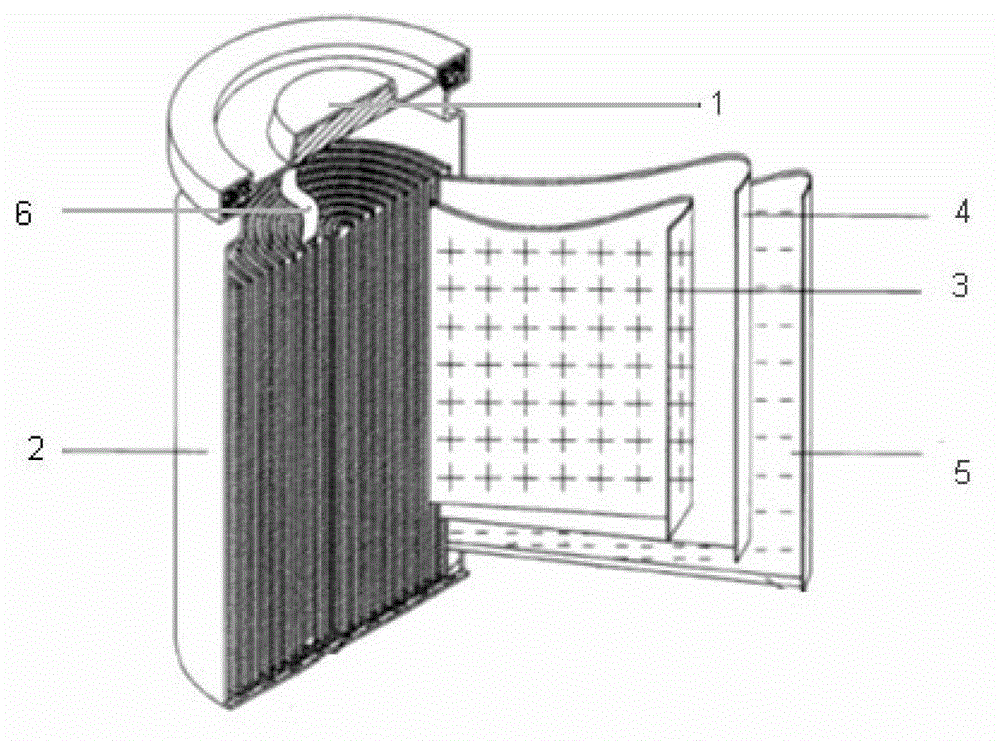

Secondary battery with high-ratio discharge characteristics and production method of secondary battery

A high-rate discharge, secondary battery technology, applied in secondary battery manufacturing, battery pack components, circuits, etc. The effect of low connection resistance and good high-rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

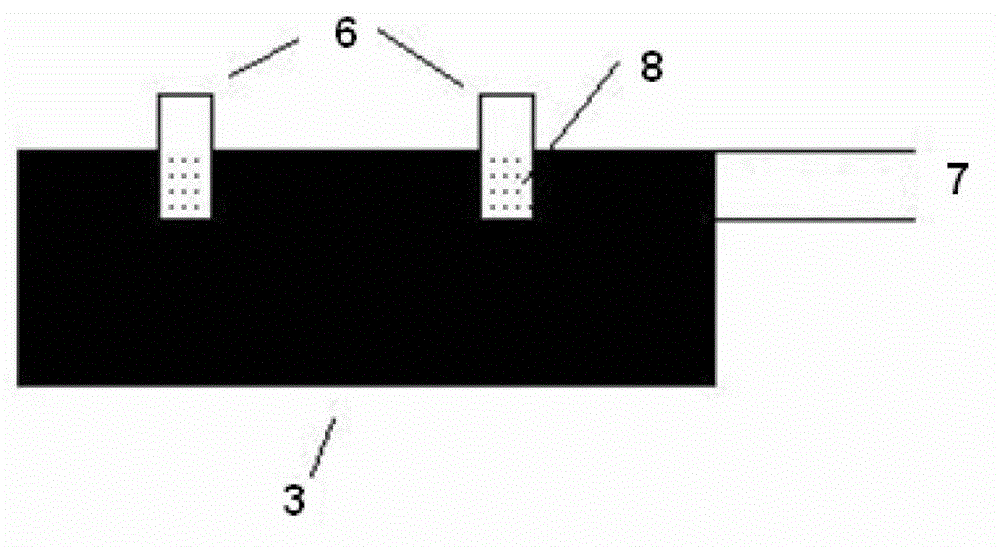

Method used

Image

Examples

Embodiment 1

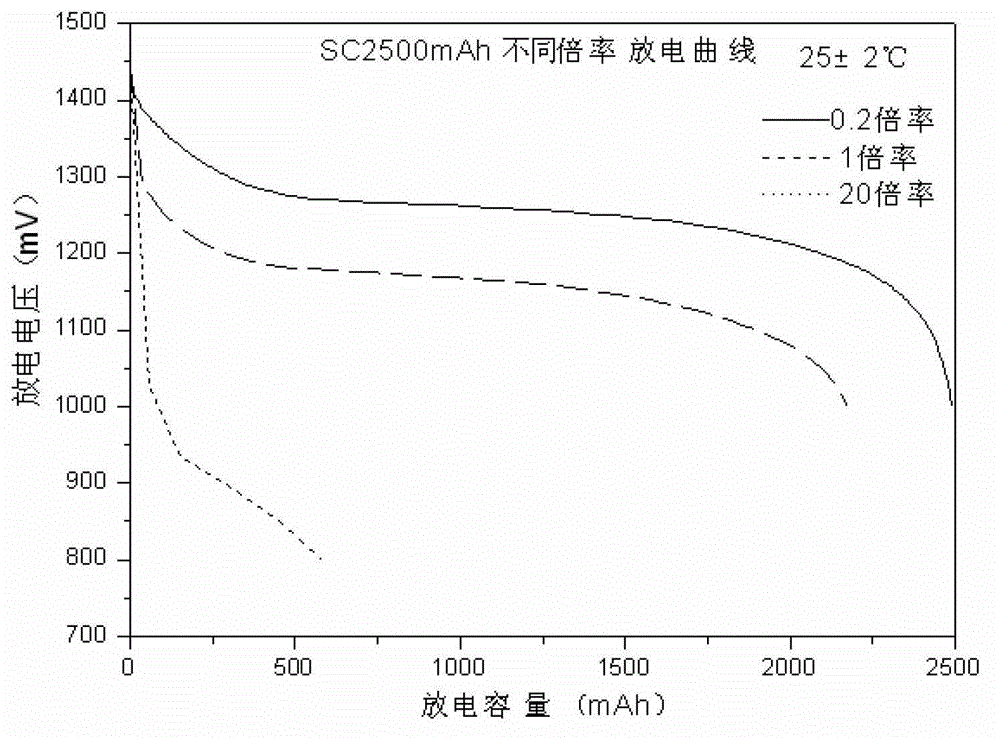

[0038] SC-type Ni-MH battery with a nominal battery capacity of 2500mAh is used. There are 3 tabs connected between the positive plate and the cap. The distance between the tabs is 6.0mm. The spot welding depth of the positive plate is 0.5mm. The material of the tabs is pure nickel strip. , the size is: width 3.5mm, thickness 0.10mm, the number of spot welding points of the positive tab is 1 point, and the battery internal resistance of this battery is 25mΩ. When the battery is discharged under the discharge current conditions of 0.2 rate (0.5 amps), 1 rate (2.5 amps), and 20 rate (50 amps), the 0.2 rate discharge capacity can reach 65% of the nominal capacity, and the 1 rate discharge capacity can reach the nominal capacity. 49% of the capacity, and the 20-rate discharge capacity is zero.

[0039] A method for preparing the above-mentioned secondary battery with high rate discharge characteristics, the method comprises the following steps:

[0040] 1) According to the number...

Embodiment 2

[0054] SC-type Ni-MH battery with a nominal capacity of 2500mAh is used. There are 3 lugs connecting the positive plate and the cap. The distance between the tabs is 6.0mm. The spot welding depth of the positive plate is 1.0mm. The material of the tabs is pure nickel strip. , the size is: width 3.5mm, thickness 0.10mm, the number of spot welding points of the positive tab is 2 points, and the battery internal resistance of this battery is 21mΩ. The battery is discharged under the discharge current conditions of 0.2 rate (0.5 ampere), 1 rate (2.5 ampere), and 20 rate (50 ampere). The 0.2 rate discharge capacity can reach 69% of the nominal capacity, the 1 rate discharge capacity can reach 55% of the nominal capacity, and the 20 rate discharge capacity is zero.

[0055] The preparation method of the above secondary battery is shown in Example 1.

Embodiment 3

[0057] SC-type Ni-MH battery with a nominal battery capacity of 2500mAh is used. There are 3 tabs connected between the positive plate and the cap. The distance between the tabs is 6.0mm. The spot welding depth of the positive plate is 1.5mm. The material of the tabs is pure nickel strip. , the size is: width 3.5mm, thickness 0.10mm, the number of spot welding points of the positive tab is 3 points, and the battery internal resistance of this battery is 18mΩ. The battery is discharged under the discharge current conditions of 0.2 rate (0.5 ampere), 1 rate (2.5 ampere), and 20 rate (50 ampere). The 0.2 rate discharge capacity can reach 86% of the nominal capacity, the 1 rate discharge capacity can reach 67% of the nominal capacity, and the 20 rate discharge capacity is zero.

[0058] The preparation method of the above secondary battery is shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com