Liquid seal anti-vibration device and manufacturing method thereof

An anti-vibration device, liquid technology, applied in the direction of spring/shock absorber manufacturing, shock absorber, shock absorber-spring combination, etc., can solve the problem of flow reduction, internal pressure cannot be fully increased, and vibration reduction cannot be achieved Capability and other issues, to achieve the effect of preventing deformation, reducing vibration, and high vibration damping function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

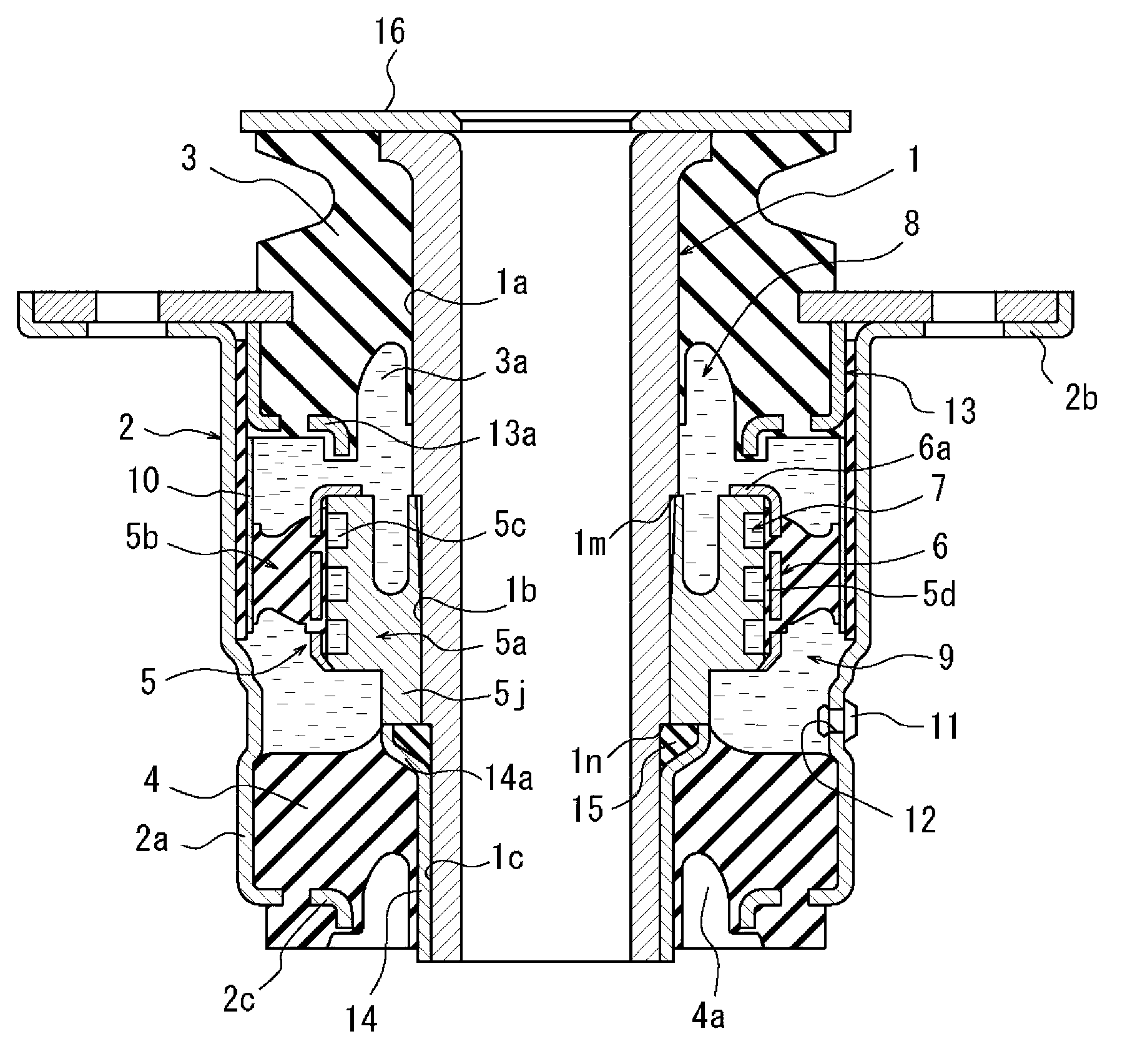

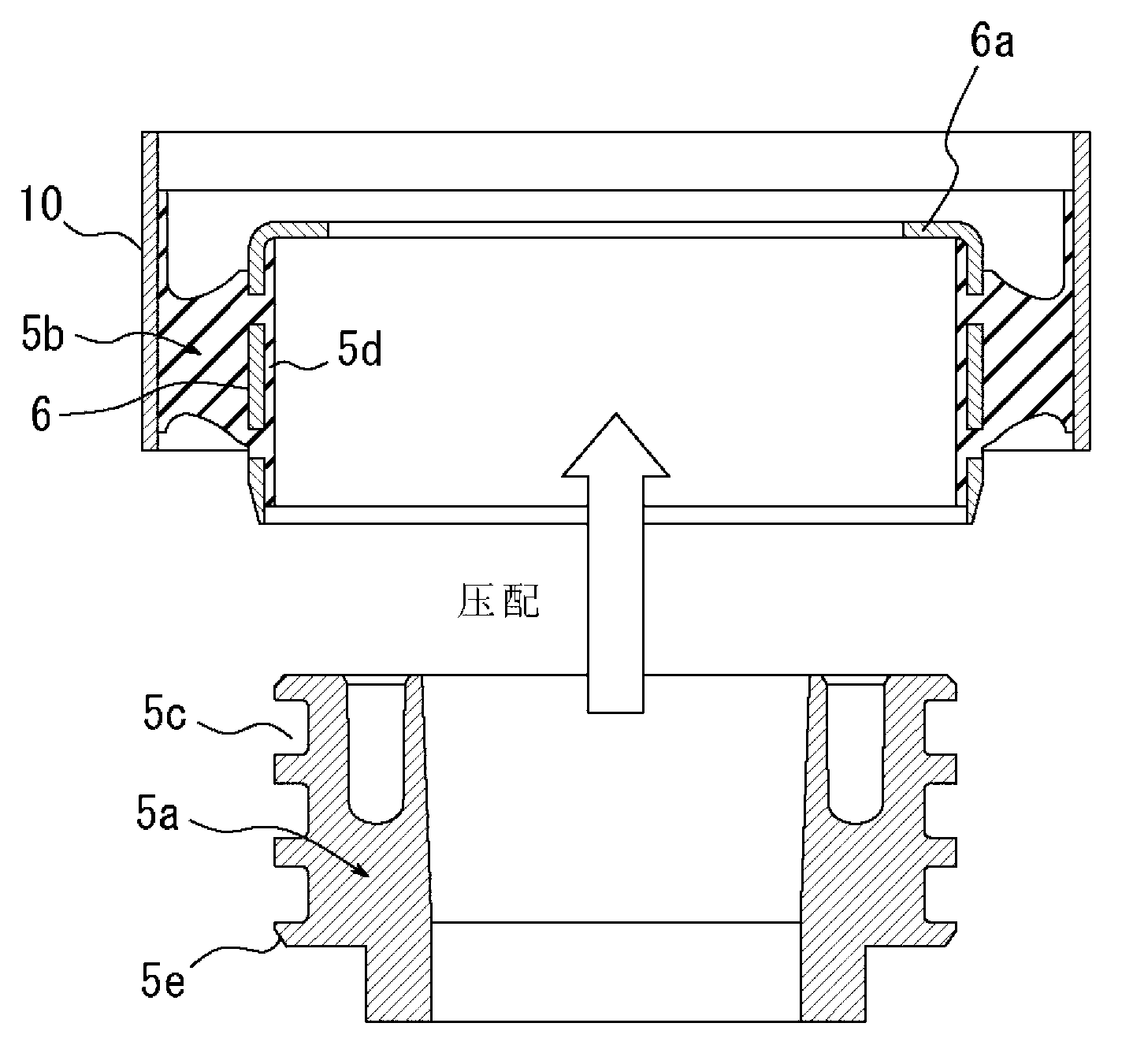

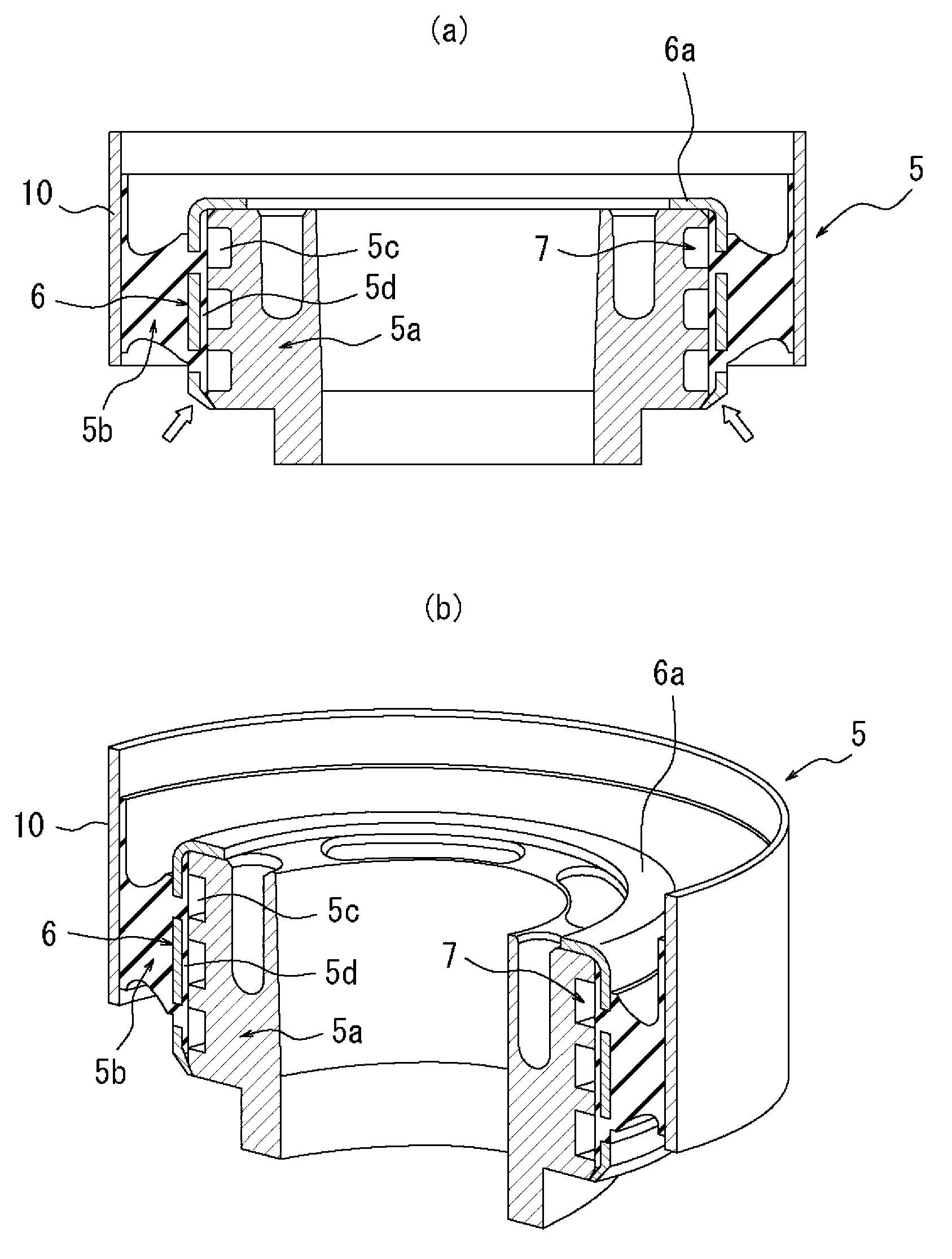

[0074] refer to figure 1 In the embodiment shown, reference numeral 1 designates an inner cylinder provided with a flange at the upper end shown. The inner cylinder 1 may be made of metal and is generally cylindrical. Reference numeral 2 denotes an outer cylinder which is spaced apart from the inner cylinder 1 on the circumferential outside of the inner cylinder 1 and provided with an upper end flange. The outer cylinder 2 is also generally cylindrical and may also be made of metal.

[0075] The inner cylinder 1 and the outer cylinder 2 are connected to each other in a liquid-tight manner by a rubber body 3 at the illustrated upper end and a rubber body 4 at the illustrated lower end. The rubber bodies 3 , 4 are spaced apart from each other in the axial direction of the inner cylinder 1 and the outer cylinder 2 and are arranged between the inner cylinder 1 and the outer cylinder 2 . The space defined by the inner cylinder 1 , the outer cylinder 2 and the rubber bodies 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com