Engine suspension component and motor tricycle

A technology of three-wheeled motorcycles and engines, which is applied in the field of three-wheeled motorcycle parts and three-wheeled motorcycles, and can solve the problems of large shear force and lateral vibration, reduced spring suspension effect, and inability to withstand shear force, etc., to achieve Good bonding strength, obvious friction holding effect, and the effect of increasing lateral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

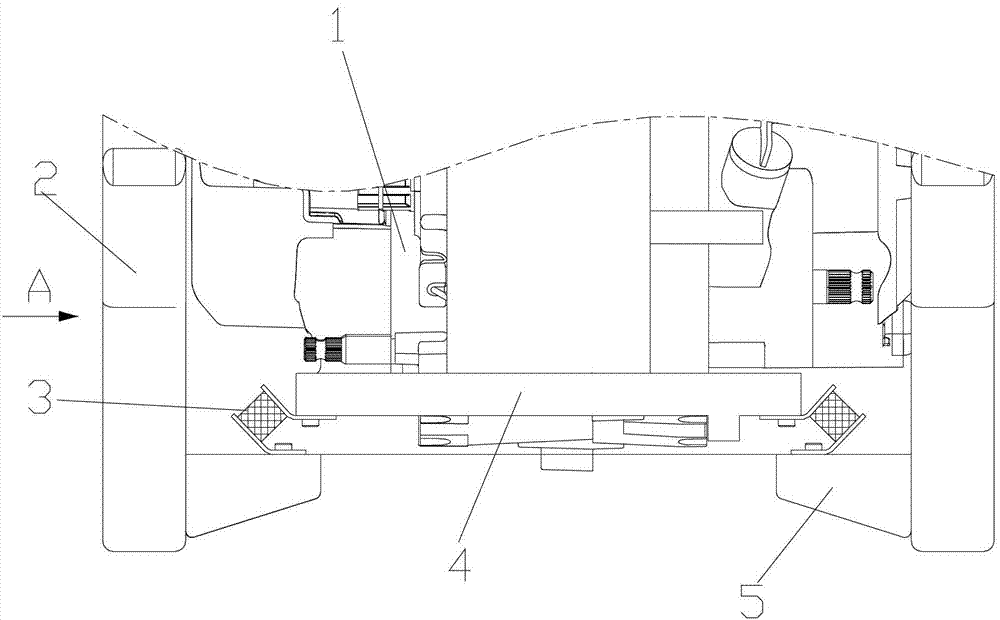

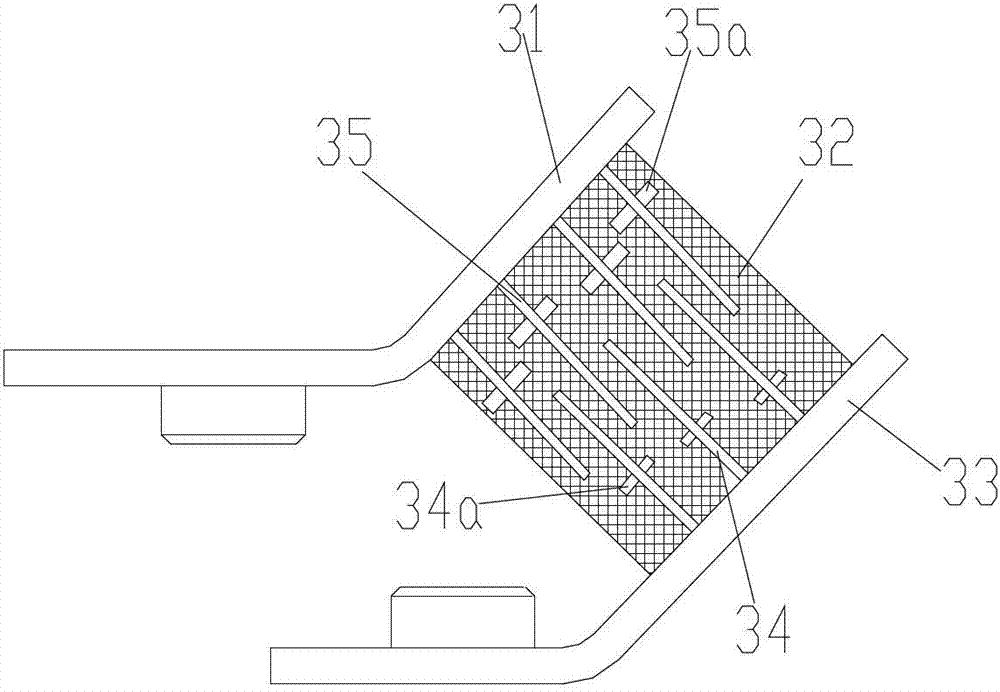

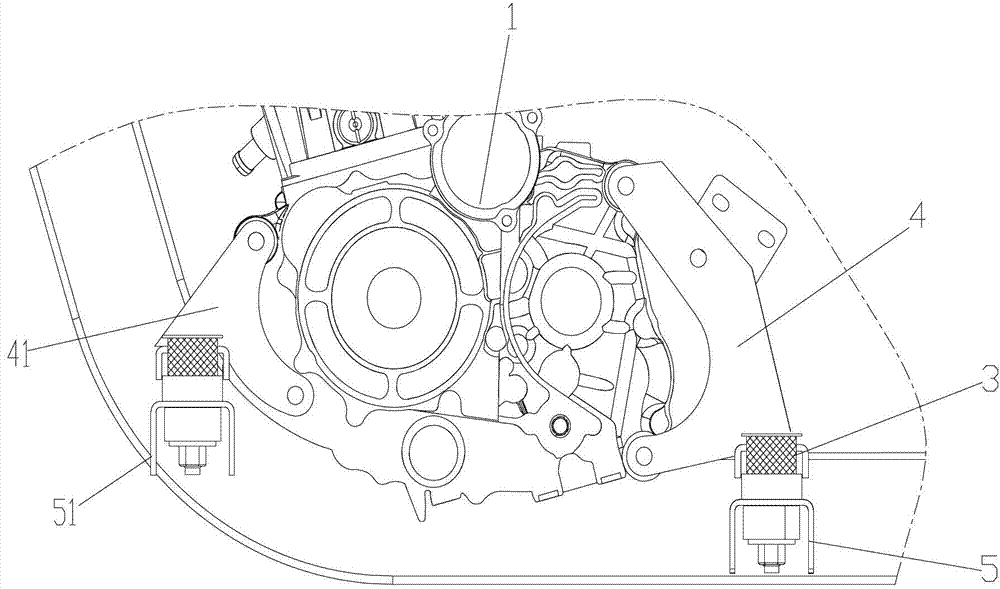

[0020] figure 1 It is a schematic diagram of the installation structure of the present invention, figure 2 It is a schematic diagram of the suspension structure of the present invention, image 3 for figure 1 View along direction A, as shown in the figure: the engine suspension assembly of this embodiment includes suspensions 3 arranged at the four corners of the engine to support it, and each of the suspensions 3 includes an upper support plate 31 for fixed connection with the engine , the lower support plate 33 for fixed connection with the vehicle frame and the elastic pad 32 fixed between the upper support plate 31 and the lower support plate 33, the elastic pad 32 of each suspension 3 supports the engine 1 from bottom to top The horizontal direction is inclined to the center; the support direction of the elastic pad 32 to the engine 1 refers to the pressure produced by the engine on the elastic pad due to gravity, and the direction of the reaction force produced by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com