Embedded-type combined wall, and construction method of embedded-type combined wall

A construction method and a built-in technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing construction difficulty and project cost, saving labor and materials, improving thermal insulation performance, and reducing construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention are described in detail below.

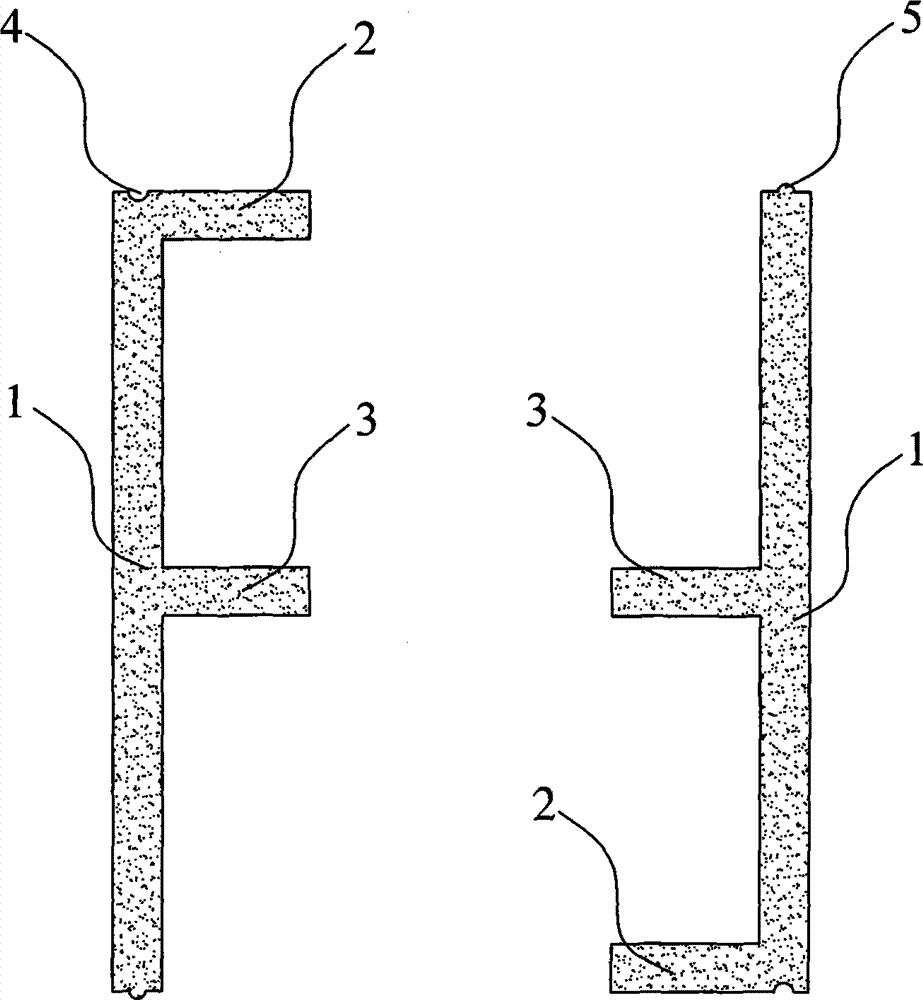

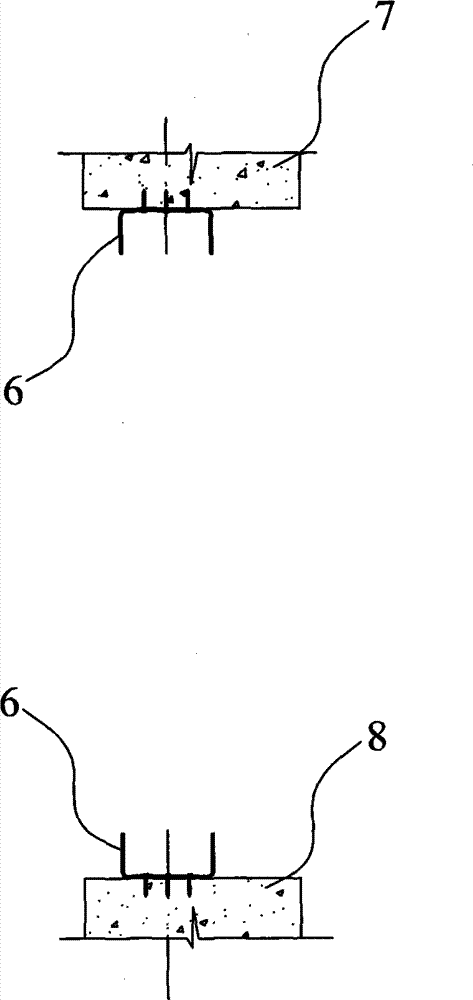

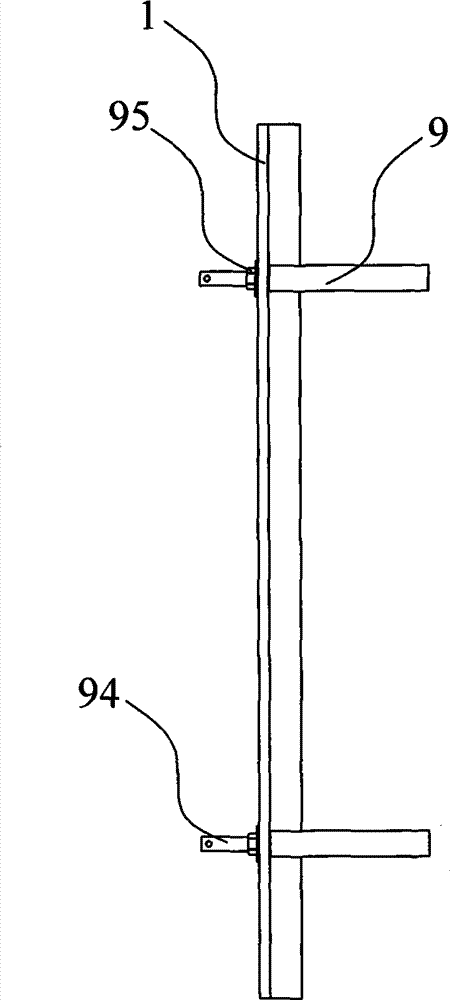

[0035] figure 1 It is a schematic diagram of the cross-sectional structure of the embedded composite wall of the present invention, such as figure 1 As shown in , the chiseled combined wall of the present invention includes a wall panel 1, and the top of one end of the wall panel 1 is integrally provided with a top wing plate 2 perpendicular to the wall panel 1, and the middle part of the wall panel 1 is provided with a top wing plate 1. The middle wing board 3 is arranged in parallel, and the wall board is integrally formed in the shape of an English letter F; the top end of the wall board 1 is provided with a concave hole 4, and the bottom end of the wall board 1 is provided with a convex strip 5 that is fitted and spliced with another same wall board Two wallboards are spaced apart to form a composite wall, wherein one wallboard is vertically mirrored and horizontally mirrored relative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com