High-temperature resistance plastics centrifugal pump

A high temperature resistant, centrifugal pump technology, used in pumps, pump devices, pump components, etc., can solve problems such as affecting the normal use of the pump, short operating life, and single-end mechanical seals without cooling and flushing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

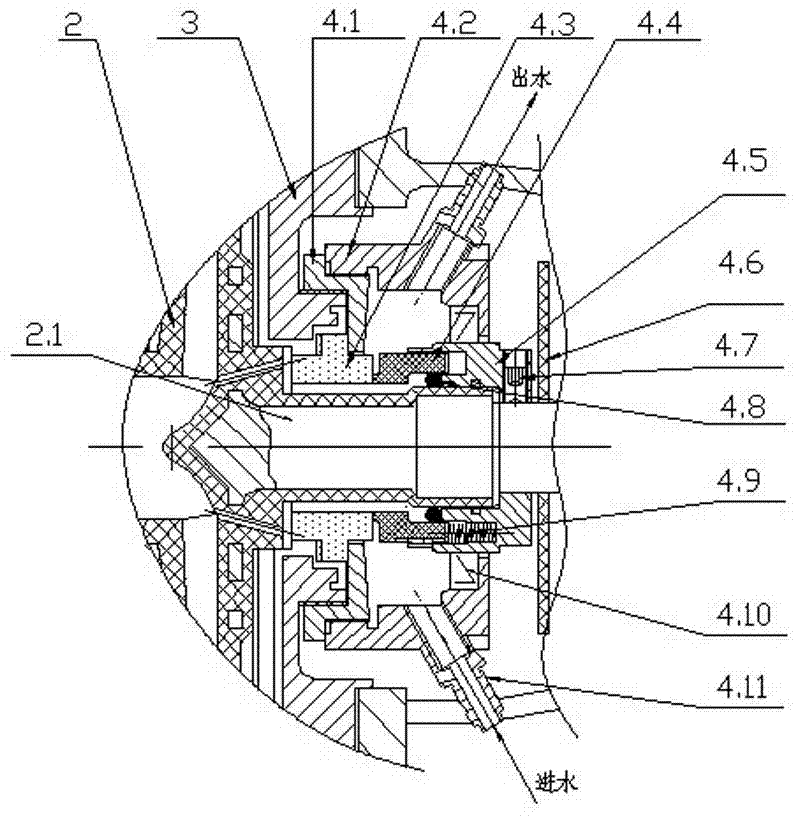

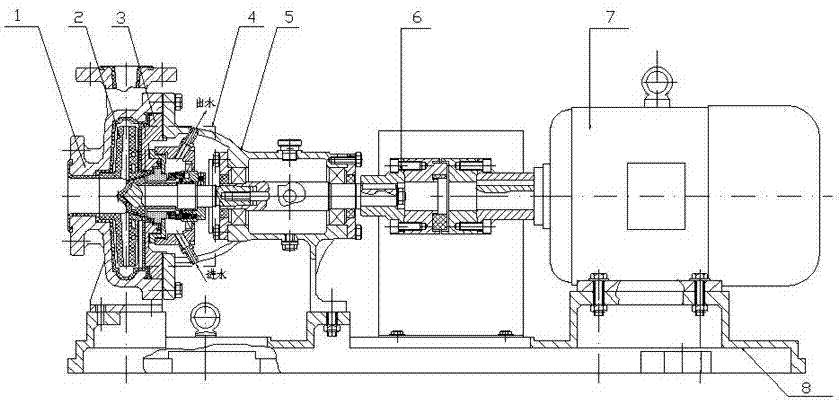

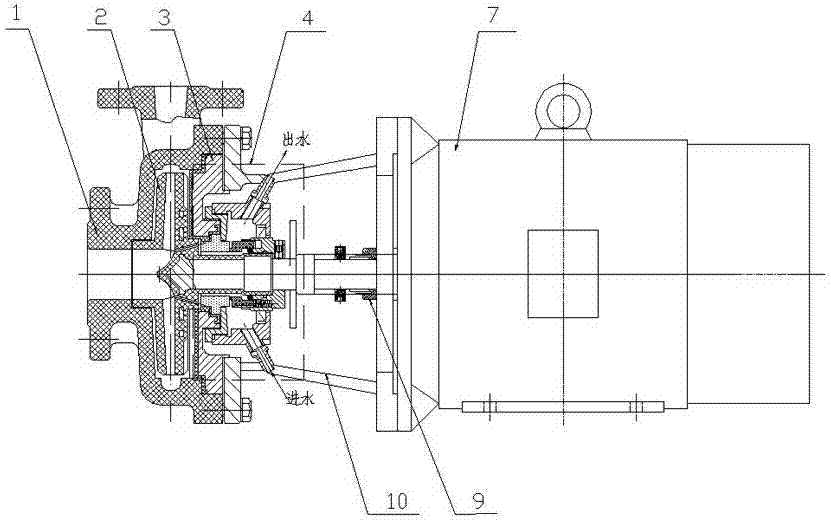

[0018] Example 2: The high temperature resistant plastic centrifugal pump of the present invention is divided into connection type (see figure 2 Shown) and direct connection (see image 3 Shown); the connection type is composed of the pump body, pump cover, impeller, sealing parts, bearing seat parts, coupling, motor, and base; the direct connection type is composed of the pump body, pump cover, impeller, sealing parts, intermediate bracket, and motor , Tensioning connection device composition; two forms of flow parts (pump body, pump cover, impeller) and sealing parts are common, the flow parts are made of high temperature and corrosion resistant plastic by molding, the pump body can be made of all plastic or lined with plastic Form, the impeller is made of a metal shaft and plastic as a whole, and the metal shaft is partially exposed for the assembly of the mechanical seal, and the mechanical seal components (see figure 1 Shown), with cooling water flushing device, design coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com