Precision and efficiency detection device for small planetary roller screw pair

A planetary roller and efficiency detection technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as reading deviation, torque measurement error, and failure to consider system errors, etc., to avoid installation Non-parallel, easy to install and disassemble, and improve the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0037] The purpose of the present invention is to overcome the deficiencies in the existing structure and provide a device capable of detecting the accuracy and efficiency of small planetary roller screw pairs, which is used for detecting the accuracy and efficiency of small planetary roller screw pairs .

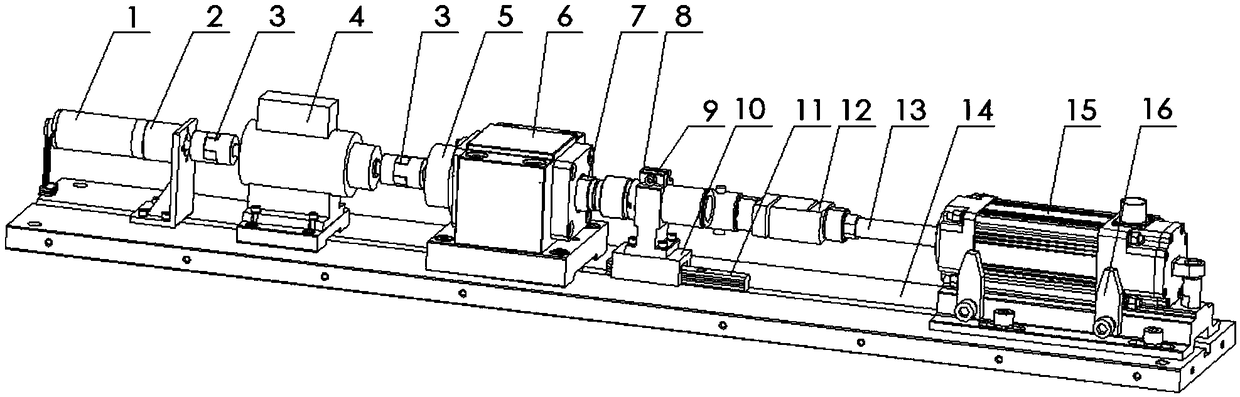

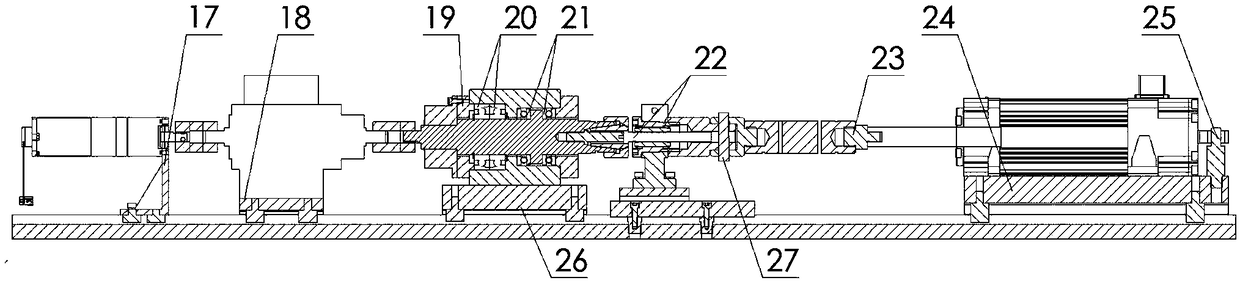

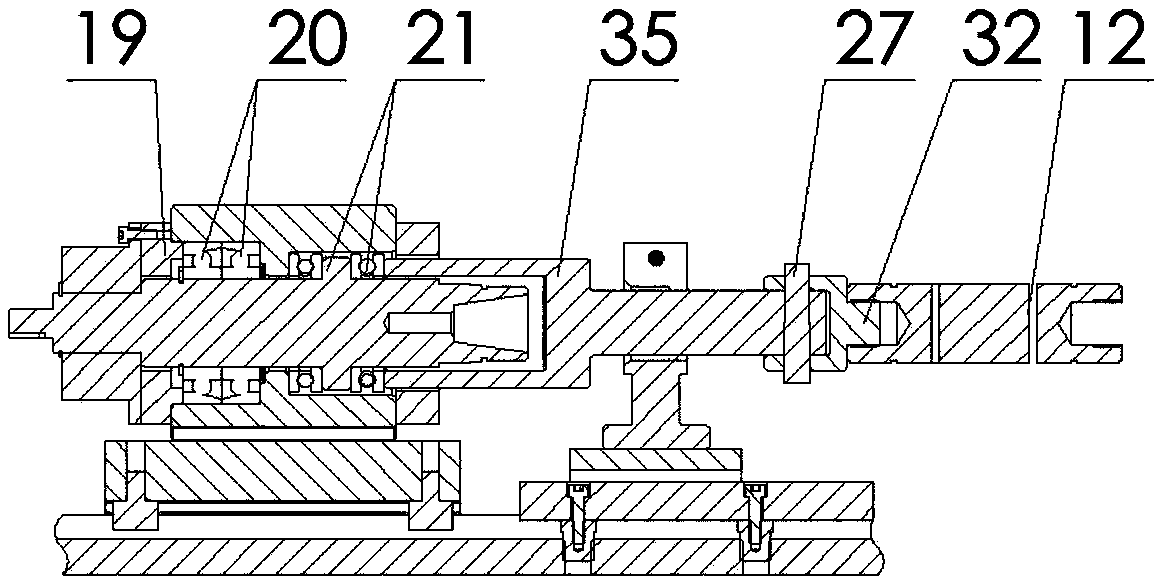

[0038] refer to Figure 1 to Figure 7 , a small planetary roller screw pair accuracy and efficiency detection device, including: servo motor (1); reducer (2); coupling (3); torque sensor (4); rotary encoder (5) ;Bearing seat (6); Mounting shaft (7); Nut sleeve (8); Locking screw (9); Slider (10); Guide rail (11); Pull pressure sensor (12); Load output shaft (13 ); base plate (14); electromechanical actuator (15); limit pressure plate (16); motor mounting bracket (17); torque sensor mounting plate (18); locking flange (19); angular contact ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com