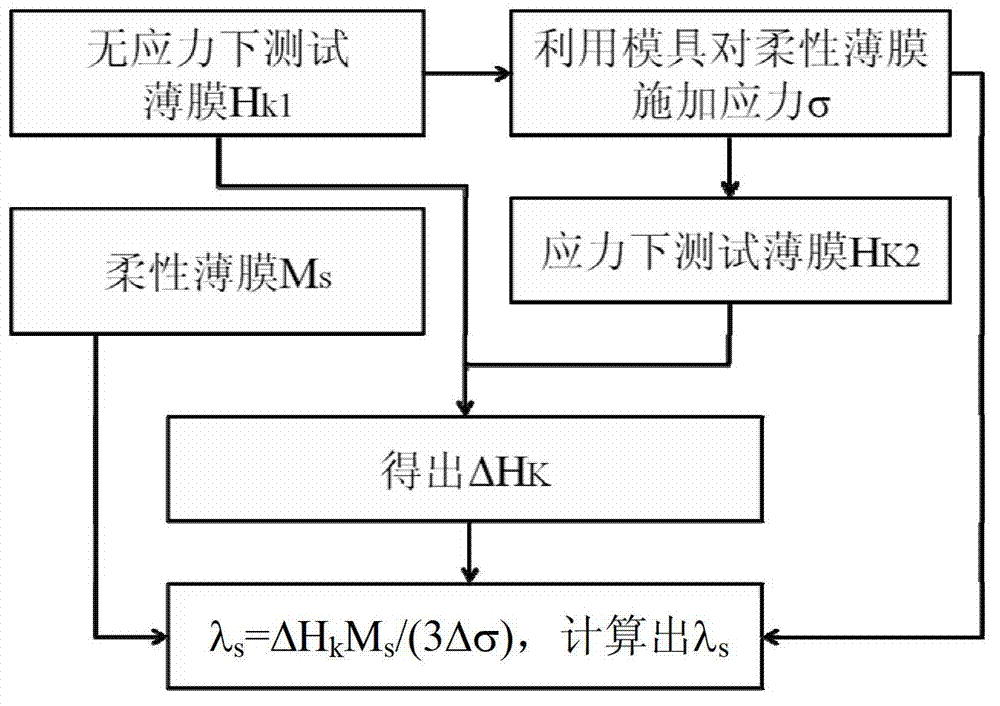

Method for measuring flexible magnetic film saturated magnetostriction coefficient

A technology of magnetostrictive coefficient and magnetic thin film, which is applied in the measurement of magnetostrictive performance and magnetic performance, etc., can solve the problems of complexity, no measurement method, difficult calibration, etc., and achieve the effect of low cost and fast measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the flexible magnetic film is FeGa(10nm) / IrMn(20nm) / Ta(30nm) / PET exchange bias film, that is, a Ta film layer with a thickness of 30nm is sequentially stacked on a flexible PET substrate, and the thickness is The measurement of the saturation magnetostriction coefficient of the 20nm IrMn thin film layer and the FeGa thin film layer with a thickness of 10nm includes the following steps:

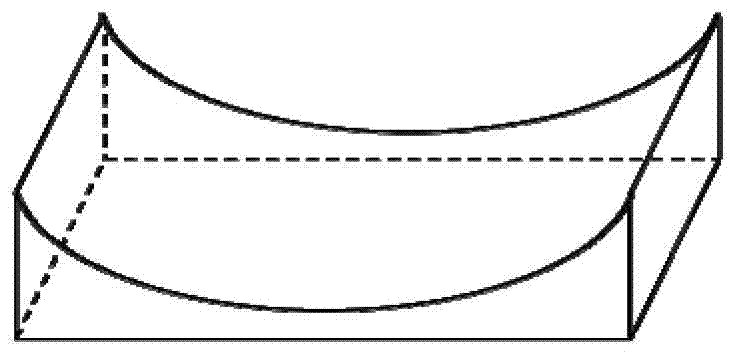

[0040] (1) Place the film sample on the surface of the flat mold 301, such as Figure 2a As shown, the mold 301 does not apply strain to the film sample to obtain an unstrained film sample 302; the flat mold 301 is installed on the MOKE test system, and the magnetization curve of the unstrained film sample 302 placed on the surface of the mold 301 is measured in longitudinal mode Measured, the hard axis magnetization curve is shown as the solid line in Figure 2, and the anisotropic field H of the strain-free film sample 302 is obtained k1 =170Oe;

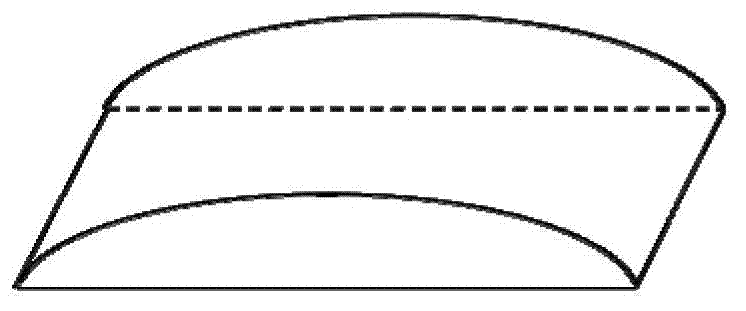

[0041] (2) Use a convex...

Embodiment 2

[0046] In this embodiment, the flexible magnetic film is a FeGa (20nm) / PET film, that is, an FeGa film layer with a thickness of 20nm is grown on a flexible PET substrate. The saturation magnetostriction coefficient measurement of the film includes the following steps:

[0047] (1) Similar Figure 2a As shown, the film sample is placed on the surface of a flat mold, and the mold does not apply strain to the film sample to obtain an unstrained film sample; the flat mold is installed on the MOKE test system, and the unstrained film placed on the surface of the flat mold is aligned in the longitudinal mode The magnetization curve of the sample is measured. The hard-axis magnetization curve is shown as the solid line in Figure 3, and the anisotropic field H of the strain-free film is obtained. k1 =250Oe;

[0048] (2) Similar Figure 2b As shown, using a convex non-magnetic mold with a fixed radius of curvature of ρ=7.4cm, the film sample is placed on the curved surface of the convex mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com