Structure for ensuring coaxiality of assembled lens cones

A technology of coaxiality and lens barrel, applied in installation, optics, instruments, etc., can solve the problems of keeping the lens distance unchanged, difficult to guarantee the coaxiality, and tilting the lens resolution, and achieves fast upright assembly, low cost, Effects with low assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

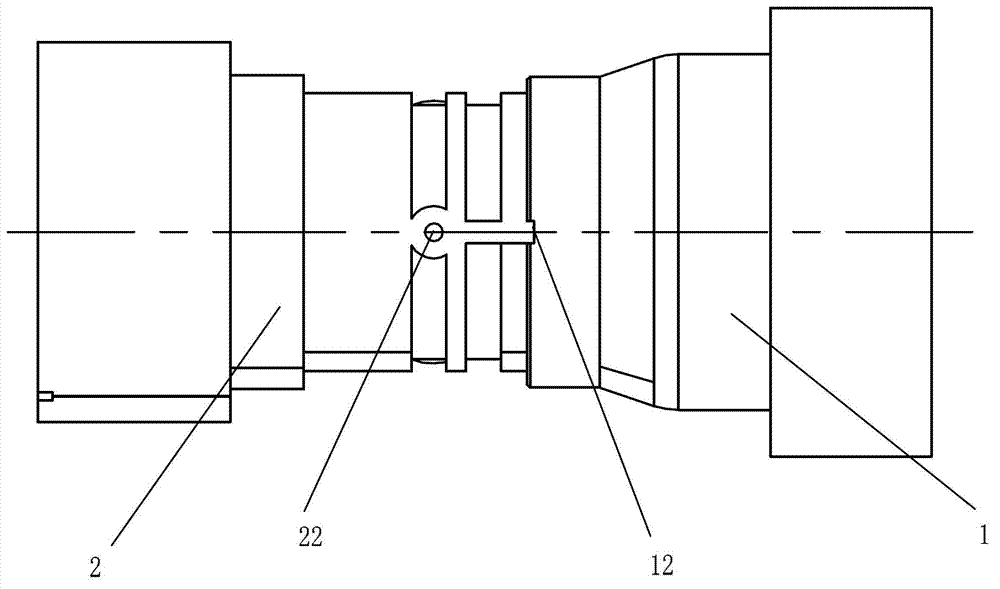

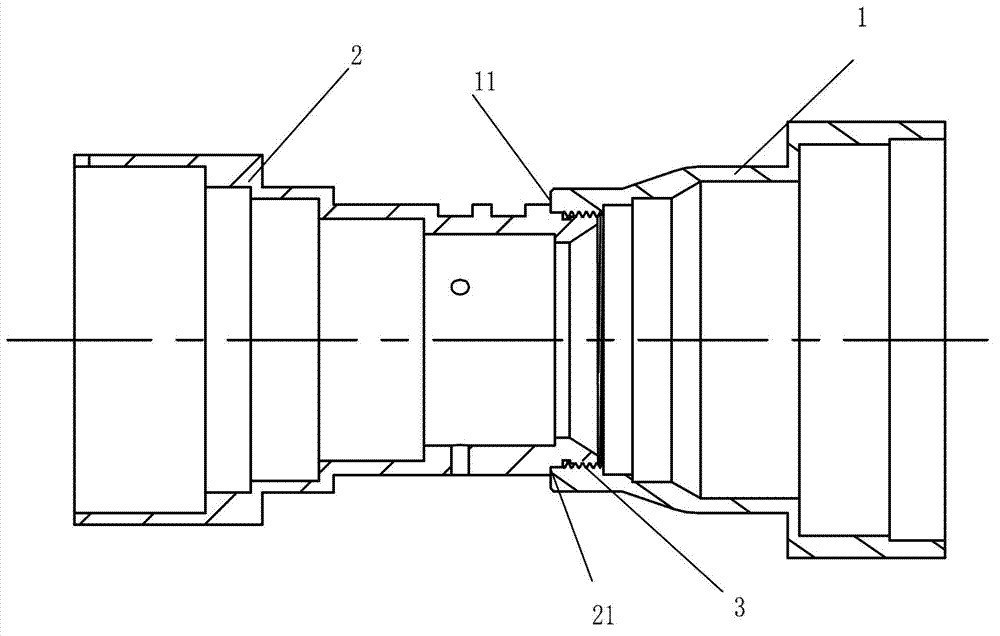

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

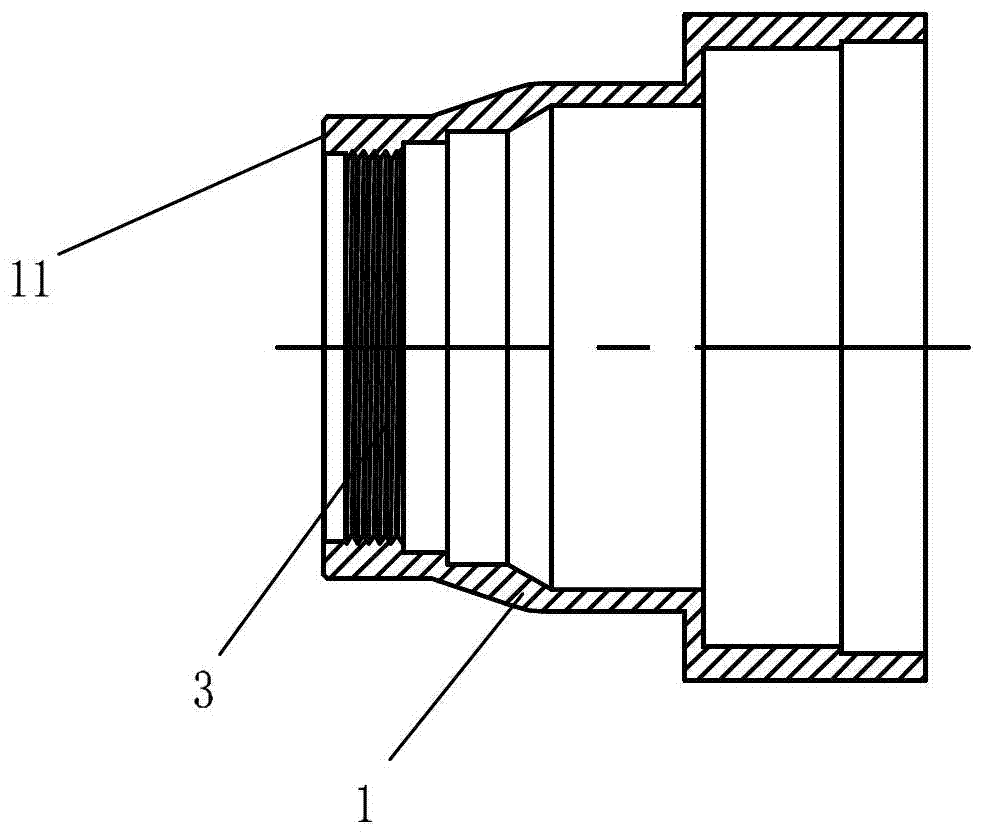

[0022] As shown in the figure, a structure to ensure the coaxiality of the lens barrel after assembly includes a front lens barrel 1 and a rear lens barrel 2 . The joints of the front lens barrel 1 and the rear lens barrel 2 are provided with threads 3 and connected by threads to make the two lens barrels connected and fixed, wherein the threads of the front lens barrel 1 are internal threads, and the threads of the rear lens barrel 2 are external threads .

[0023] A front convex ring platform 11 is provided on the threaded front end of the front lens barrel 1 , and a rear convex ring platform 21 that can be closely attached to by the front convex ring platform 11 is provided at the thread end of the rear lens barrel 2 . Such as figure 1 , 4 As shown, when the two threads are tightened, the two platforms are pressed against each other. Both the front convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com