Stress removing and reinforcing method used for steel construction truss

A technology for steel trusses and buildings is applied in the field of stress relief and reinforcement, which can solve the problems of weakening and bearing large stress, large amount of reinforcement works, and long construction period, and achieves the effects of good reinforcement effect, less material consumption and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

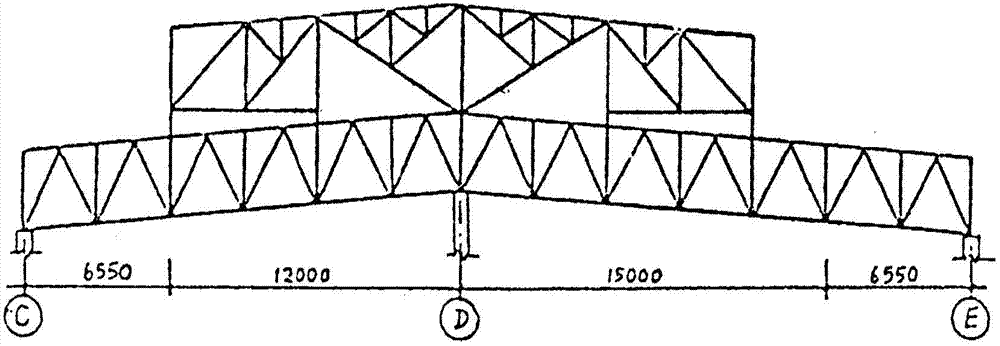

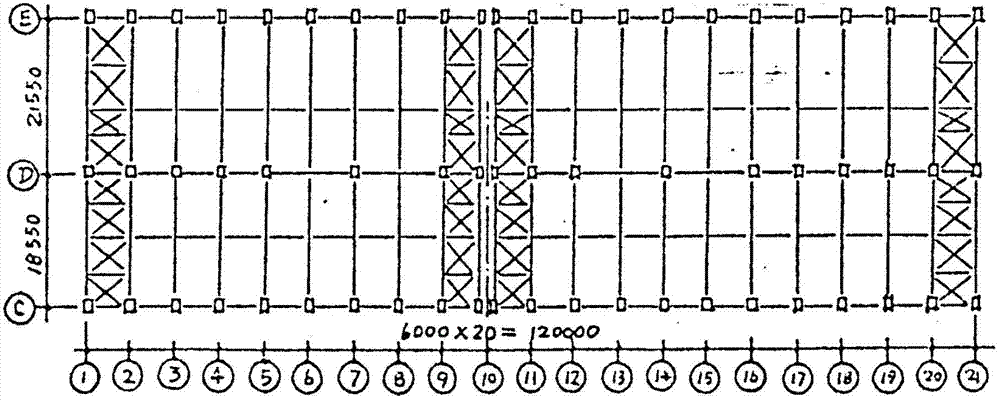

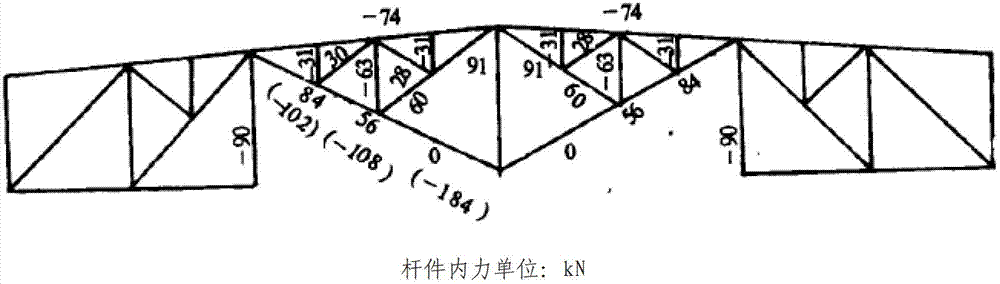

[0045] a kind of like Figure 1~3 The steel truss stress relief and reinforcement construction method of a steelmaking main factory building is shown. The main factory building is a four-span factory building. After being put into production, 80% of the main oblique rods of the skylight frame have obvious out-of-plane bending deformation, the maximum bending deformation lateral displacement reaches 170mm, and there are obvious buckling characteristics.

[0046] Concrete implementation scheme has following steps successively:

[0047] 1) Detect the actual stress state of the steel truss of the building, provide a basis for analyzing and judging the causes of hidden dangers and establish a steel truss calculation model, avoid blindness in the design of steel truss stress relief and reinforcement schemes, and adopt the slotting method on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com