Improved alkylation process

A technology for alkylating aromatics and alkylating agents, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, catalysts, etc., and can solve problems such as lack of activity, increased requirements for catalysts in liquid phase processes, and no teaching of improvement methods. , to achieve the effect of reducing catalyst poisons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

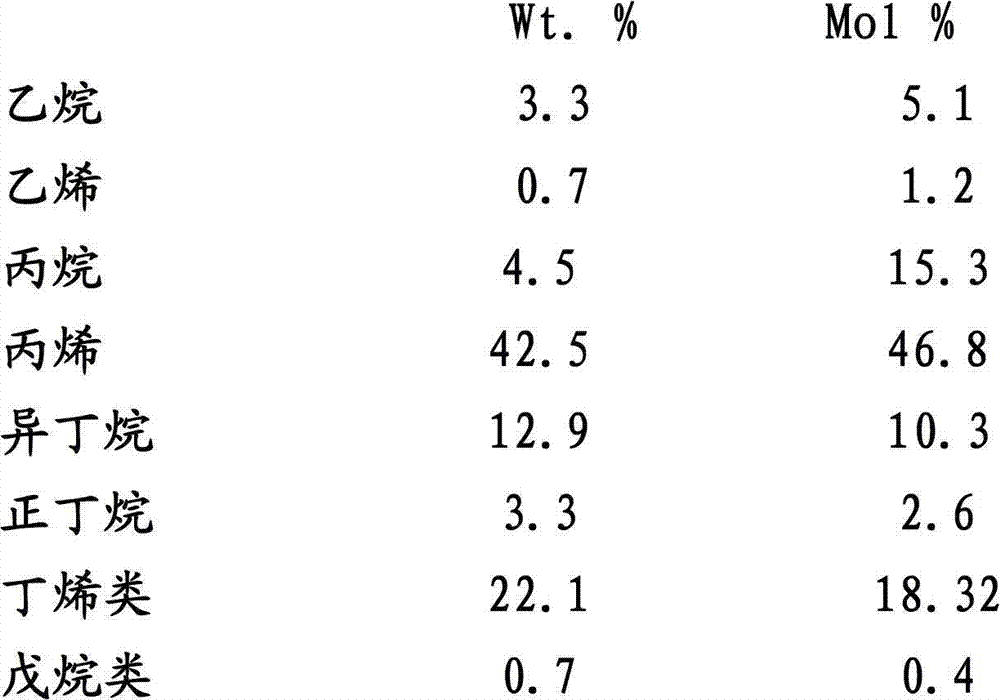

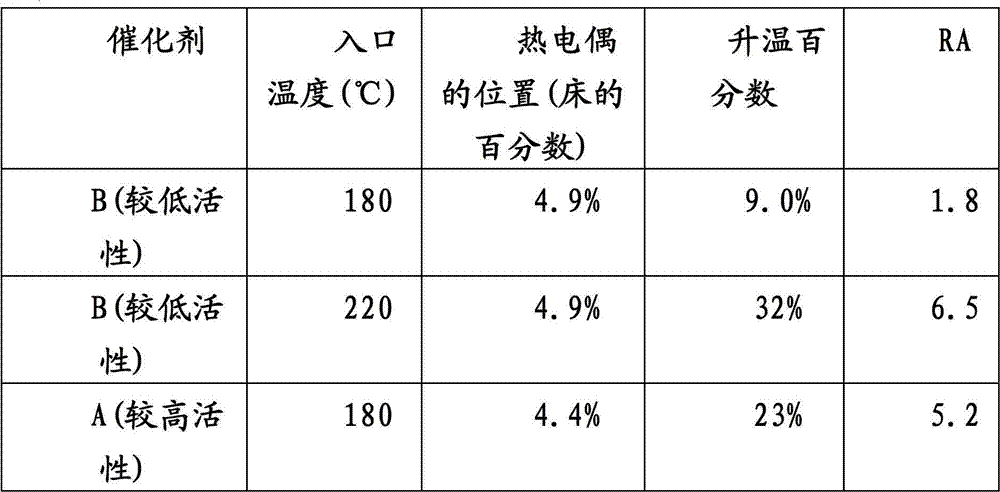

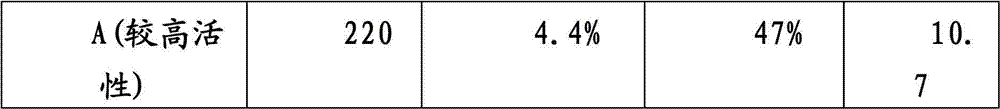

Embodiment 1

[0091] An amount of 16 g of material formulated in the form of 1 / 20 inch (0.13 cm) four-lobed granules containing MCM-49 (which has a MWW framework) was placed in the treatment zone (as a treatment composition) and in the alkylation reaction zone ( as a catalyst composition) in both places. The surface area / surface volume ratio of the quatrefoil material is about 180-220 in -1 (71-87cm -1 ). Benzene / ethylene molar ratio 50:1-70:1, about 60:1 at ambient pressure, WHSV about 21hr based on benzene -1 And at 180°C (liquid phase), benzene and ethylene containing 0.3 wppm of nitrogen in the form of N-formylmorpholine (hereinafter "N") were fed into the treatment zone. The effluent from the treatment zone is then fed to the alkylation reaction zone maintained at a temperature of 180°C mixed with ethylene and the mixture is in the liquid phase with a benzene / ethylene molar ratio of 18:1, and Based on ethylene, WHSV is 0.77hr -1 . The catalyst composition in the reaction zone was...

Embodiment 2

[0093] An amount of 16 g of MCM-49 (which has a MWW framework structure) formulated in the form of 1 / 20 inch (0.13 cm) four-lobed granules, crushed into 200-250 micron sized particles was placed in the treatment area (as Treatment composition) and an amount of 28 g of material formulated as 1 / 20 inch (0.13 cm) four-lobed particles containing MCM-49 was placed in the alkylation reaction zone (as the catalyst composition). The surface area / surface volume ratio of comminuted material (treatment composition) in the treatment zone is about 600-770 in -1 (236-303cm -1 ). The surface area / surface volume ratio of the quatrefoil material (catalyst composition) in the alkylation reaction zone is about 180-220 in -1 (71-87cm -1 ). Benzene / Ethylene molar ratio 9:1-26:1 at ambient pressure WHSV about 20hr based on benzene -1 And at 180°C (liquid phase), benzene and ethylene containing 0.3 wppm of N in the form of N-formylmorpholine were fed into the treatment zone. The effluent from ...

Embodiment 3

[0095] The amount of 16g containing zeolite beta (it has a *BEA framework structure) is 180-220in surface area / surface volume ratio -1 (71-87cm -1 ) of the treatment composition formulated in the form of 1 / 20 inch (0.13 cm) quatrefoil granules was placed in the treatment area and an amount of 28 g of MCM-49 formulated in the form of 1 / 20 inch (0.13 cm) quatrefoil granules The material is placed in the alkylation reaction zone. At ambient pressure, the benzene / ethylene molar ratio is about 55:1, and the WHSV is about 21hr based on benzene -1 And at 180°C (liquid phase), benzene and ethylene containing 0.3 wppm of N in the form of N-formylmorpholine were fed into the treatment zone. (However, the selectivity of the treatment composition is very poor, producing about 2.5-4.0 times the amount of diethylbenzene as a MWW catalyst.) The effluent from the treatment zone mixed with ethylene is then fed to a In the reaction zone at temperature, and the mixture is in the liquid phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com